Feather spin-drying device

A feather drying barrel technology, applied in drying, drying machine, drying solid materials, etc., can solve the problems of damage, feather entanglement, loss of equipment, etc., and achieve the effect of rapid drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

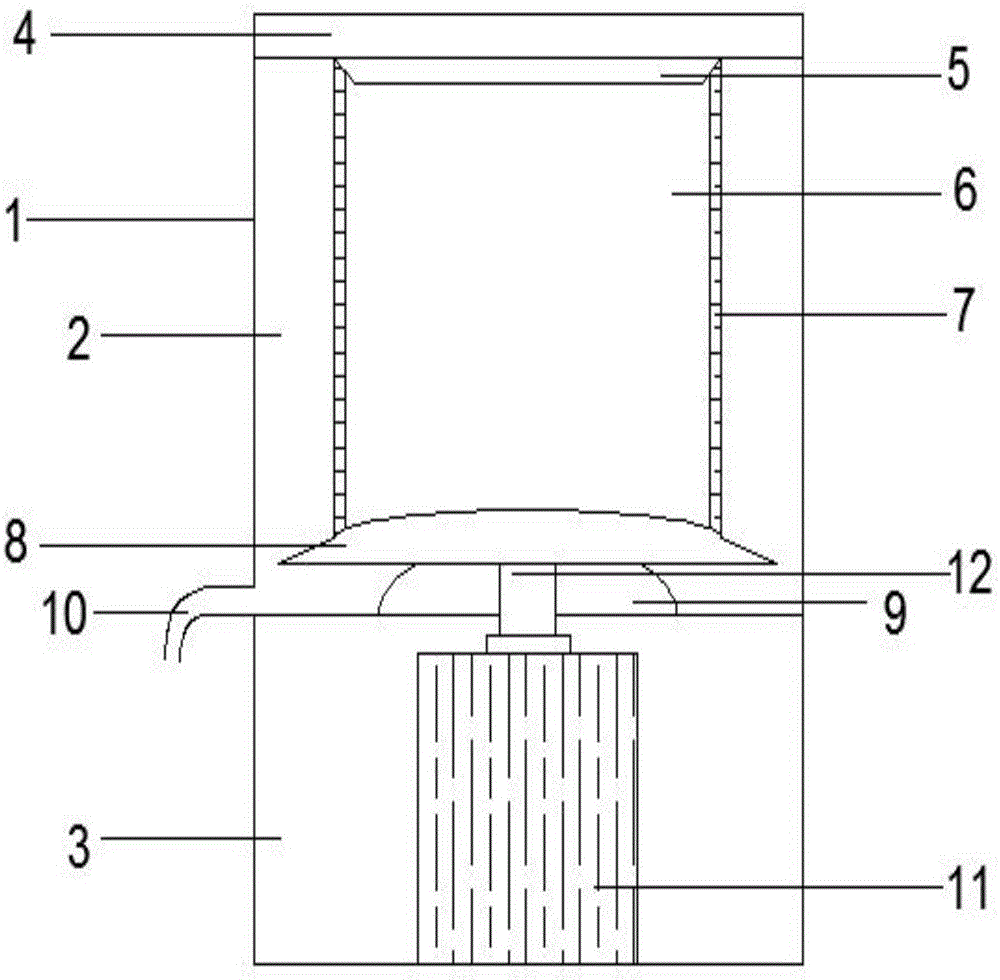

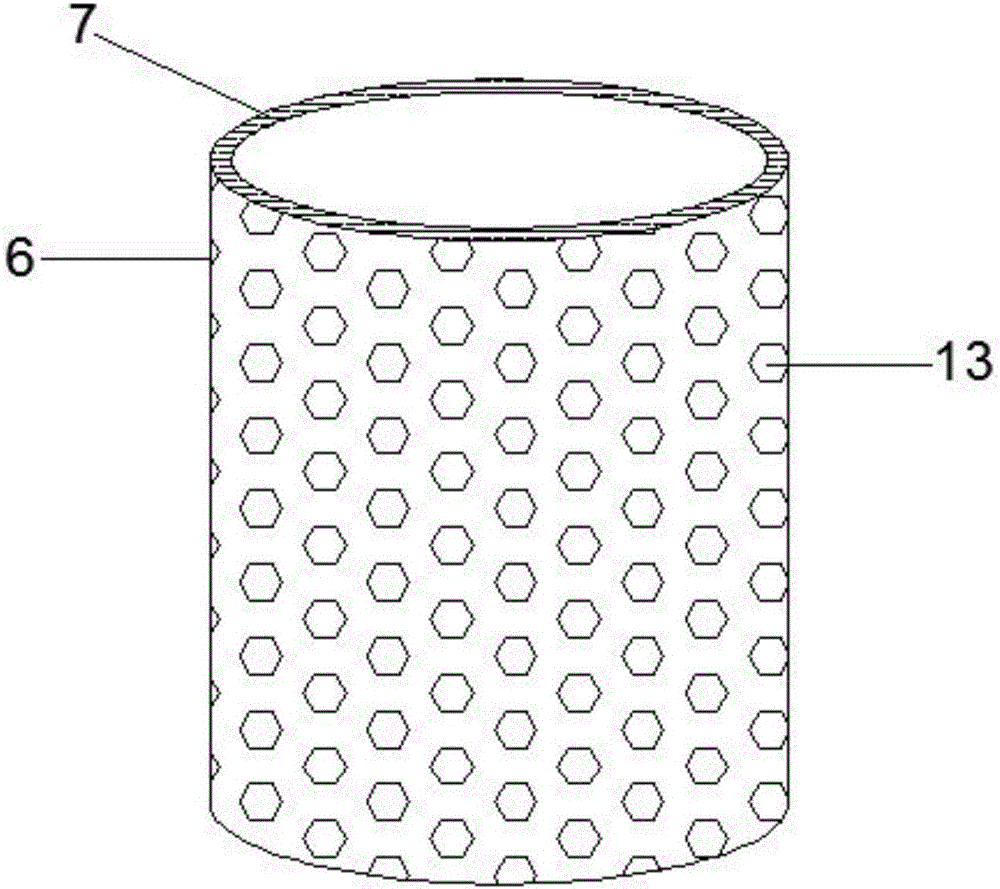

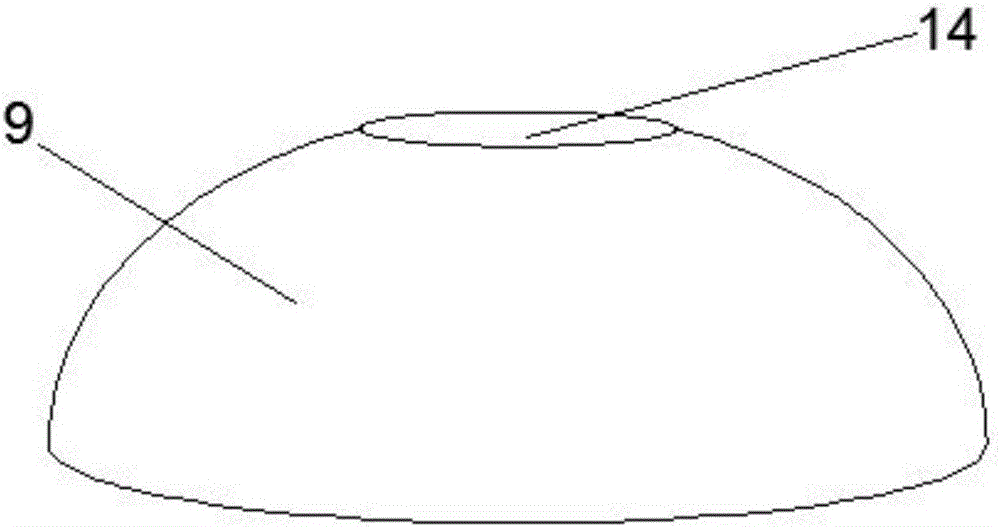

[0015] Refer to attached figure 1 , in order to make the present invention reach required technical effect. The present invention uses the following embodiments to illustrate: a feather drying device, including a drying machine, the drying machine includes a drying chamber and a driving chamber, a drying barrel is provided in the drying chamber, and a drying barrel is provided in the drying chamber. The inner wall of the drying barrel is provided with a protective layer, the side wall of the drying barrel is provided with water seepage holes, the bottom of the drying barrel is provided with a water diversion plate, the drying chamber is provided with a sealing cover, and the sealing cover is provided with a bump. The drying cavity is provided with a waterproof cover, the waterproof cover is provided with a bearing hole, the bottom side of the drying cavity is provided with a water outlet, and the water outlet is provided with a water outlet pipe, and the driving cavity is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com