Sealed washing method of slurry circulation pump in cyclohexanol unit

A technology of circulating pump and cyclohexanol, which is applied to the components, pumps, and pump elements of the pumping device for elastic fluids, can solve the problems of catalyst entry, pump damage, back-channeling, etc., and achieves sealing water pressure and The amount of flushing water is stable, eliminating cumbersome operations and ensuring stable and safe results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

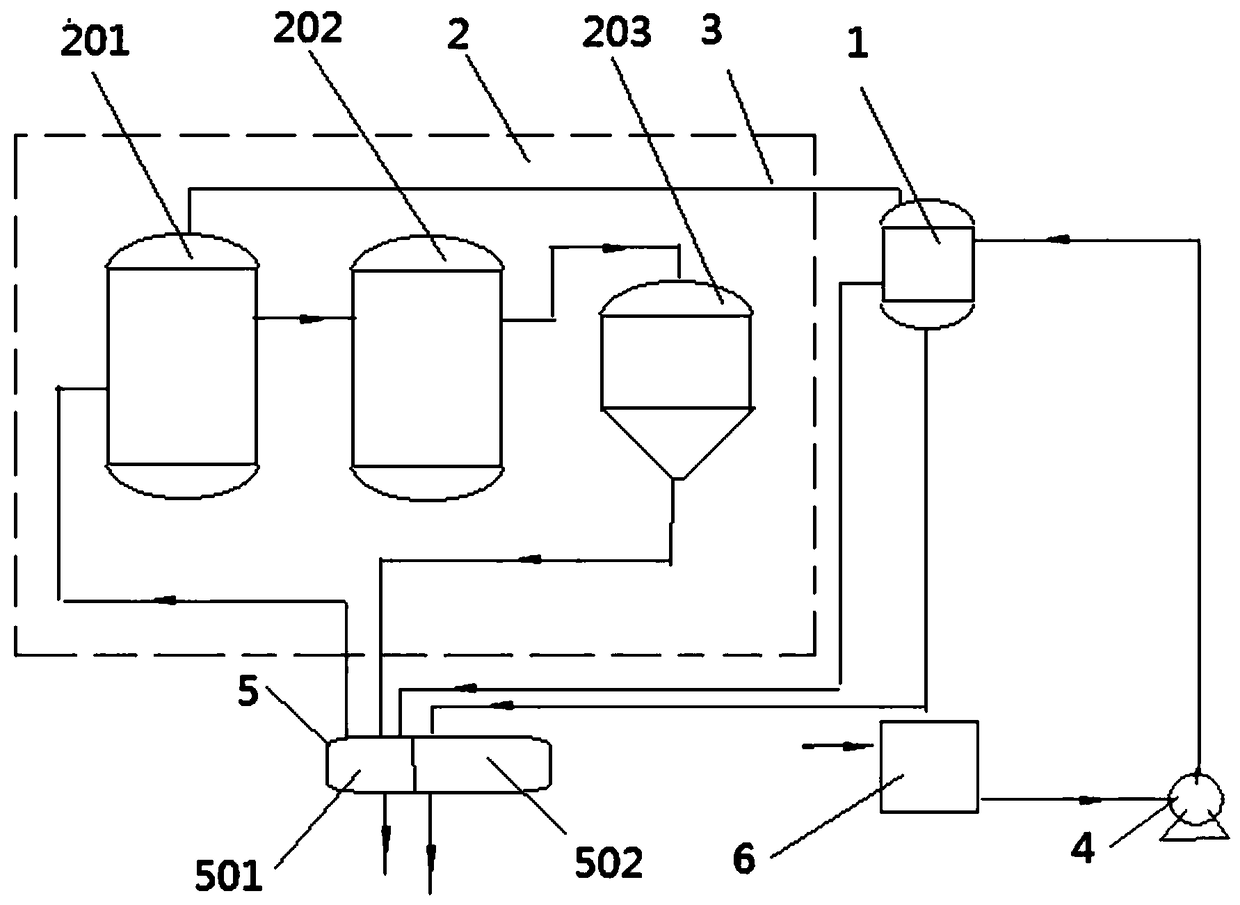

[0026] see figure 1 , the water sealing method of the slurry circulating pump in the cyclohexanol device of the present invention is realized by adopting a sealing water washing system matched with the slurry pump, the system comprising: head tank 1, reaction system 2, sealing Water pump 4, slurry circulation pump 5 and water tank 6;

[0027] The header tank 1 is connected to the reaction system 2 through a communication pipe 3 to perform pressure balance to ensure that the working pressure of the header tank is consistent with the force of the reaction system;

[0028] The sealed water pump 4 is connected with the head tank 1 through a pipeline, and is used to send the water in the water tank 6 into the head tank 1;

[0029] The first outlet of the elevated tank is connected to the pump chamber 501 of the slurry circulation pump through a pipeline, and the second outlet is connected to the motor chamber (502) of the slurry circulation pump through a pipeline;

[0030] The i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com