Assembly type column-mounting auxiliary device

An installation-assisted and prefabricated technology, which is applied in construction, building structure, and building material processing, can solve problems such as slow progress, inability to guarantee, and one-to-one correspondence, so as to speed up construction progress, solve time-consuming and labor-intensive problems, and reduce construction costs. effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention and its effects will be further described below in conjunction with the accompanying drawings and embodiments.

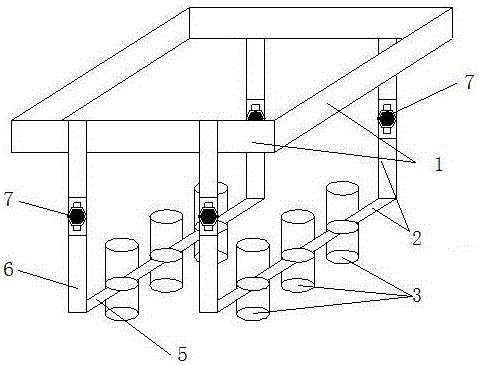

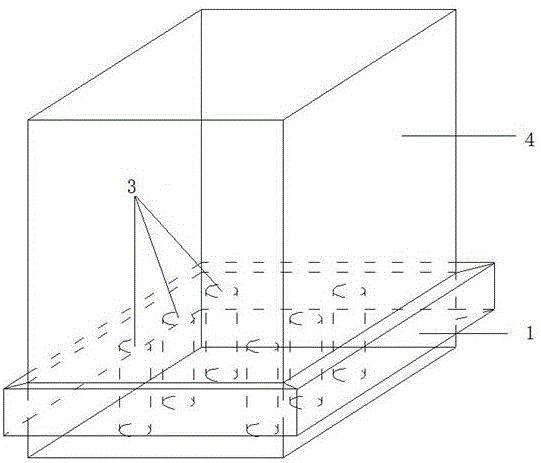

[0017] Such as figure 1 , 2 As shown, a prefabricated column installation auxiliary device includes a hoop 1, an adjusting rod 2 and a butt sleeve 3. The hoop 1 is a steel plate that is surrounded by a 10mm thick steel plate and matches the shape of the prefabricated column 4. The hoop and the adjusting rod 2 are U-shaped frames folded from 10mm thick steel plates, including the bottom horizontal rod 5 and the two side rods 6, wherein the bottom horizontal rod 5 is fixedly connected with several docking sleeves 3, and the docking sleeves 3 are made of It is cut from a steel pipe, and the two side rods 6 are connected with a length expander 7, and the length of the two side rods 6 is adjusted through the length expander 7, so that the bottom horizontal rod 5 and the docking sleeve 3 on it move up or down. The ends of the side bars 6 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com