Cement-based decorative sheet with durable mirror surface effect

A cement-based, decorative board technology, applied in the field of construction and landscape decoration materials, can solve the problems of convenience in production and installation, structural safety, insufficient durability, inconformity with the development direction of concrete materials, and the decline in concrete gloss, so as to achieve beautiful appearance Long-lasting effect, good water resistance and mirror surface retention performance, raw material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

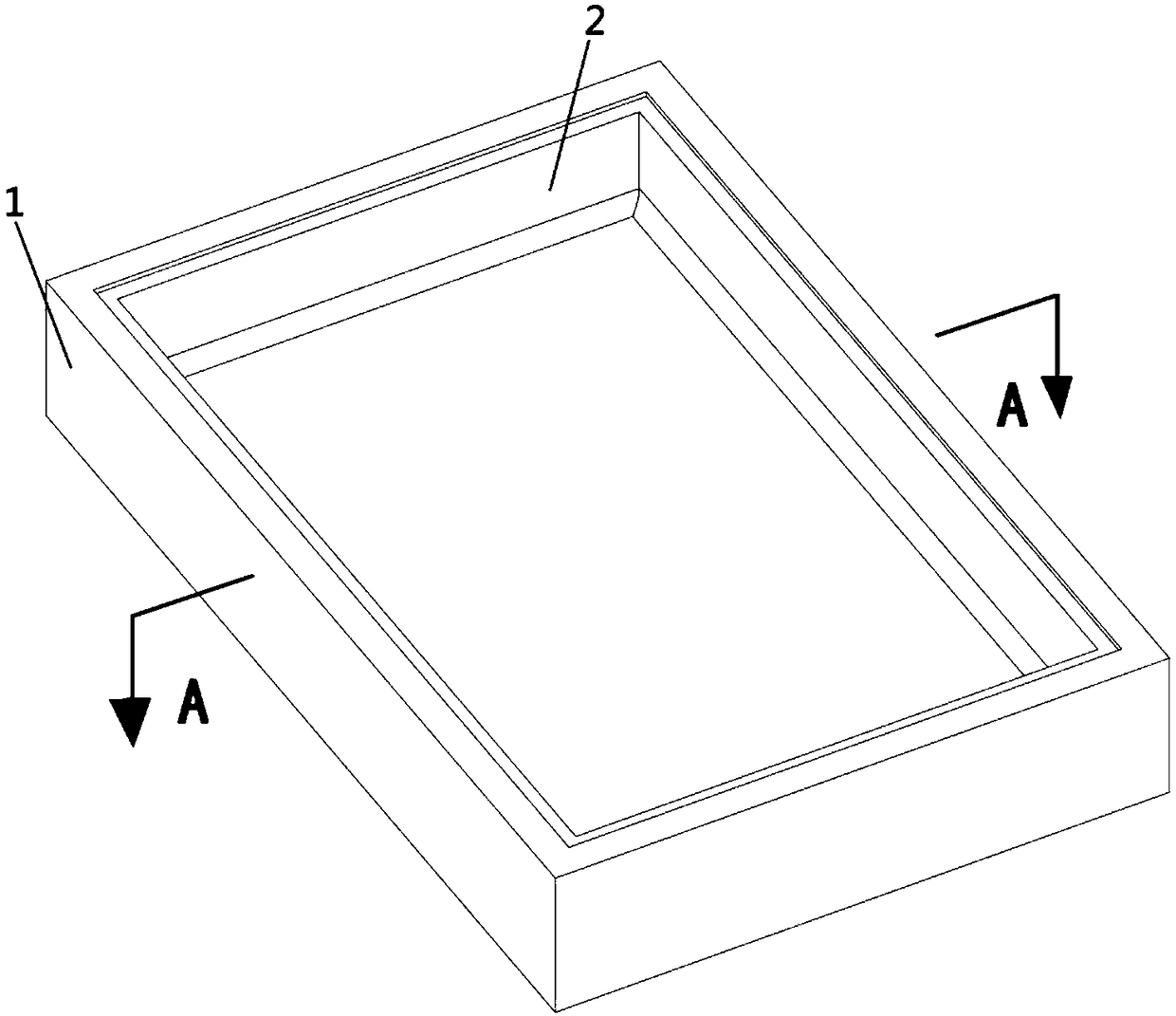

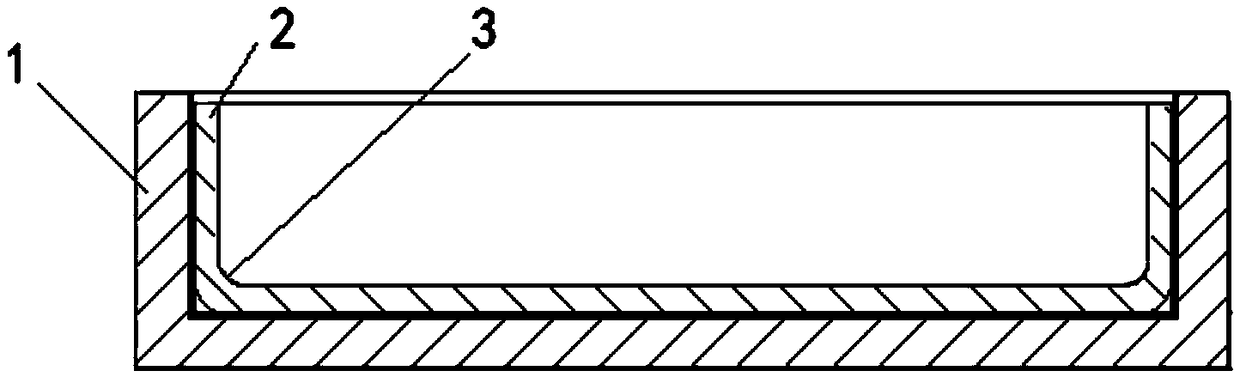

[0028] A cement-based decorative panel with a durable mirror finish made by:

[0029] (1) Weigh raw materials: Ordinary Portland cement (P.O42.5 type) 120kg, fly ash microbeads 20kg, silica fume (SiO 2 The mass content is 90%) 10kg, quartz sand (particle size ≤ 0.5mm) 160kg, and the water reducing agent is early-strength polycarboxylate high-performance water reducing agent 20HE type 6kg, polyvinyl alcohol fiber (length 6-20mm, tensile strength 1200MPa) 2.3kg, water 25kg; mix to obtain a mixture;

[0030] (2) Pour the mixture into the mold, vibrate with a vibrator for 40 seconds to discharge visible air bubbles, let it stand for 3 hours, raise the temperature to 60°C at a heating rate of 20°C / hour, and maintain it for 15 hours at a constant temperature with steam, and then maintain it at a temperature of 10°C / hour Cool down to room temperature, take off the mold, then raise the temperature to 180°C at a heating rate of 20°C / hour, keep the dry heat constant temperature for 9 ...

Embodiment 2

[0036] A cement-based decorative panel with a durable mirror finish made by:

[0037] (1) Weigh raw materials by weight: ordinary Portland cement (P.O42.5 type) 100kg, fly ash microbeads 15kg, silica fume (SiO 2 The mass content is 91%) 8kg, quartz sand (particle size ≤ 0.5mm) 150kg, water reducer (composed of 0.05kg triisopropanolamine and 4.45kg polycarboxylate high-performance water reducer Type composition) 4.5kg, polyvinyl alcohol fiber (length 6-20mm, tensile strength 1400MPa) 1.5kg, water 18.45kg; mix to obtain a mixture;

[0038] (2) Pour the mixture into the mold, vibrate with a vibrator for 15 seconds to discharge visible air bubbles, let it stand for 6 hours, raise the temperature to 50°C at a heating rate of 15°C / hour, and maintain it at constant temperature with steam for 24 hours, at a rate of 8°C / hour Cool down to room temperature, take off the mold, then raise the temperature to 120°C at a heating rate of 15°C / hour, keep the dry heat at a constant temperature...

Embodiment 3

[0046] A cement-based decorative panel with a durable mirror finish made by:

[0047] (1) Weigh raw materials by weight: ordinary Portland cement (P.O52.5) 150kg, fly ash microbeads 45kg, silica fume (SiO 2 The mass content is 92%) 12kg, quartz sand (particle size ≤ 0.5mm) 187.5kg, and the water reducing agent is early-strength polycarboxylate high-performance water reducing agent Type 7kg, polyvinyl alcohol fiber (length 6-20mm, tensile strength 1600MPa) 3.75kg, water 27.5kg; Mix well, get mixture;

[0048] (2) Pour the mixture into the mold, vibrate with a vibrator for 60 seconds to discharge visible air bubbles, let it stand for 0.5 hours, raise the temperature to 70°C at a heating rate of 18°C / hour, and maintain the steam at constant temperature for 6 hours, at a temperature of 9°C / hour Cool down to room temperature, take off the mold, then raise the temperature to 240°C at a heating rate of 18°C / hour, keep the dry heat at a constant temperature for 6 hours, and then c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com