Dyeing fabric deepening finishing agent and preparation method

A finishing agent and fabric technology, applied in the field of deepening finishing agents, can solve the problems of low surface tension, low surface energy, weak polarity, etc., and achieve the effect of improving dry and wet rubbing fastness and avoiding cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

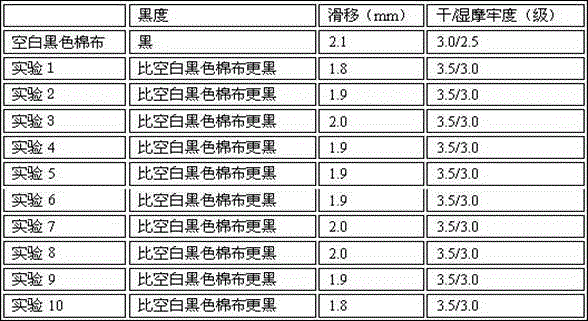

Examples

Embodiment 1

[0051] Embodiment 1, the preparation of A component water-based sealing polyurethane resin:

[0052] (1) Add 120 parts of polyoxypropylene triol (number average molecular weight 3000), 26 parts of N-methyldiethanolamine, 70.2 parts of hexamethylene diisocyanate, 55 parts of acetone, and 0.4 parts of dibutyltin dilaurate, and add In the reaction kettle, the temperature was raised to 65°C, and the reaction was carried out at 65°C for 5.5 hours;

[0053] (2) Add 16 parts of acetone oxime, react at 65°C for 3.5 hours, then;

[0054] (3) Add 25 parts of dimethyl sulfate and react at 65°C for 40 minutes;

[0055] (4) Blow the material into the emulsification kettle, cool down to 20°C, add 13 parts of glacial acetic acid into the emulsification kettle and stir evenly;

[0056] (5) Add 5.8 parts of sodium bisulfite to 560 parts of deionized water to dissolve evenly, add them to the emulsification kettle, stir and emulsify, stir for 40 minutes after emulsification is completed, filte...

Embodiment 2

[0057] Embodiment 2, preparation of A component water-based sealing polyurethane resin:

[0058] (1) Add 62 parts of polyoxypropylene triol (number average molecular weight 3000), 11.9 parts of N-methyldiethanolamine, 33 parts of hexamethylene diisocyanate, 30 parts of acetone, and 0.06 parts of dibutyltin dilaurate, and add In the reaction kettle, the temperature was raised to 75°C, and the reaction was carried out at 75°C for 5 hours;

[0059] (2) Add 7.6 parts of acetone oxime, react at 75°C for 3 hours, then;

[0060] (3) Add 11 parts of dimethyl sulfate and react at 75°C for 30 minutes;

[0061] (4) Blow the material into the emulsification kettle, cool down to 25°C, add 8 parts of glacial acetic acid to the emulsification kettle and stir evenly;

[0062] (5) Add 3 parts of sodium bisulfite to 280 parts of deionized water to dissolve evenly, add them together to the emulsification kettle, stir and emulsify, stir for 35 minutes after emulsification is completed, filter a...

Embodiment 3

[0063] Embodiment 3, preparation of A component water-based sealing polyurethane resin:

[0064] (1) Add 100 parts of polyoxypropylene triol (number average molecular weight 3000), 20 parts of N-methyldiethanolamine, 55 parts of hexamethylene diisocyanate, 40 parts of acetone, and 0.3 parts of dibutyltin dilaurate, and add In the reaction kettle, the temperature was raised to 70°C, and the reaction was carried out at 70°C for 5.5 hours;

[0065] (2) Add 12.7 parts of acetone oxime, react at 70°C for 3 hours, then;

[0066](3) Add 20 parts of dimethyl sulfate and react at 70°C for 40 minutes;

[0067] (4) Feed into the emulsification kettle, cool down to 35°C, add 11 parts of glacial acetic acid to the emulsification kettle and stir evenly;

[0068] (5) Add 4.6 parts of sodium bisulfite to 450 parts of deionized water to dissolve evenly, add them to the emulsification kettle, stir and emulsify, and stir for 40 minutes after emulsification is completed, filter and discharge to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com