A method for environmentally friendly production of meta-aramid precipitated fibers

A technology of aramid fibrid and fibril, which is applied in the fields of fiber chemical characteristics, wet spinning method, single-component copolyamide artificial filament, etc., can solve the problem that the performance of sedimentation equipment is difficult to meet market demand, and achieve The effect of strong market digestion ability, reduced sets, and reduced investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

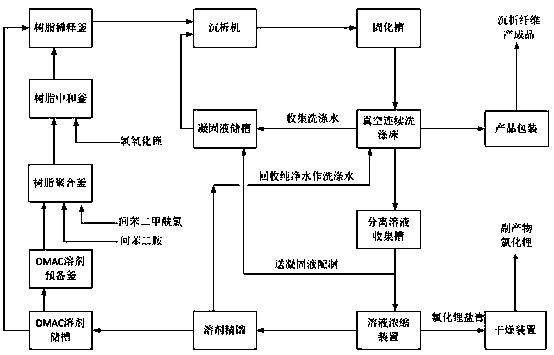

Method used

Image

Examples

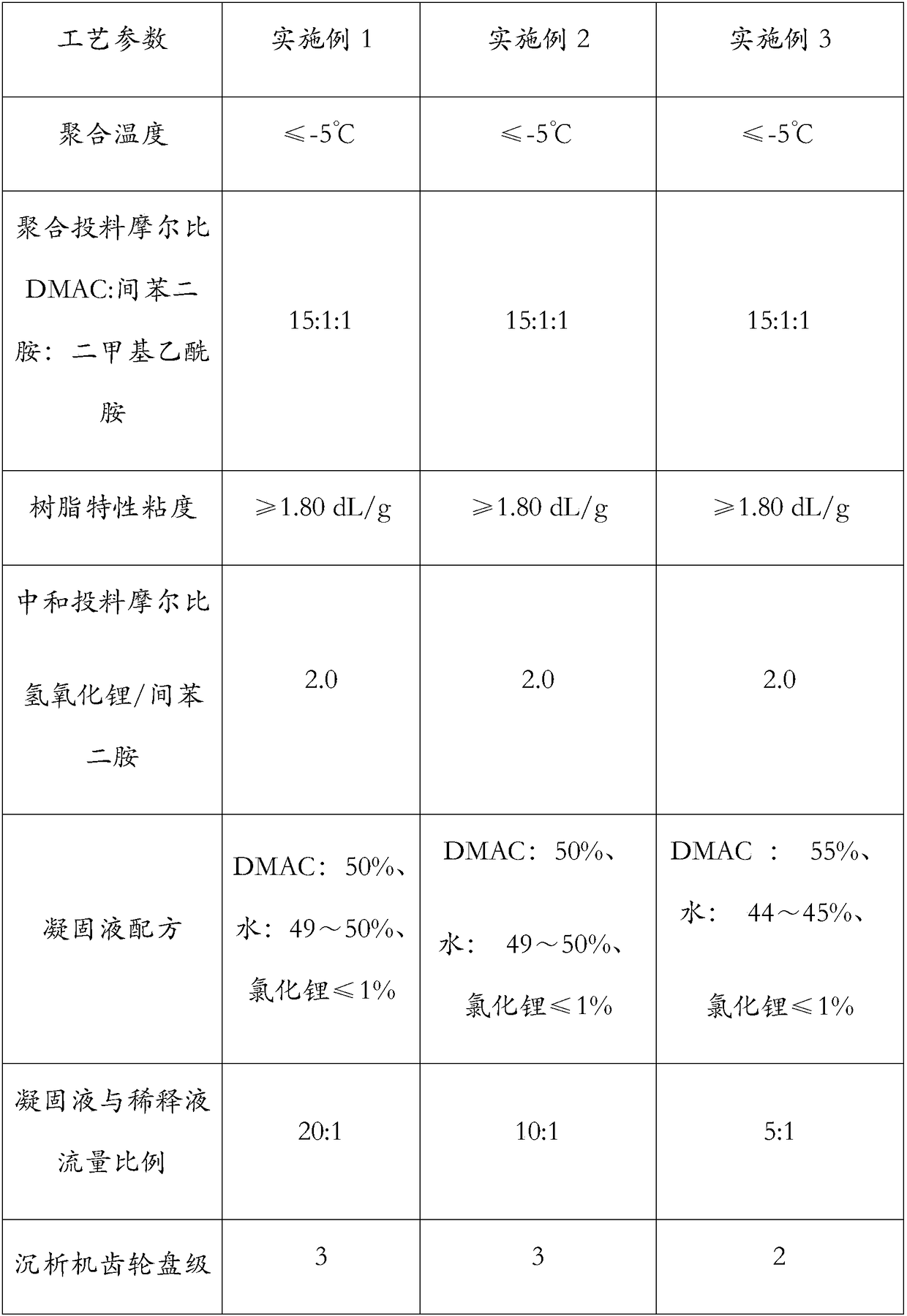

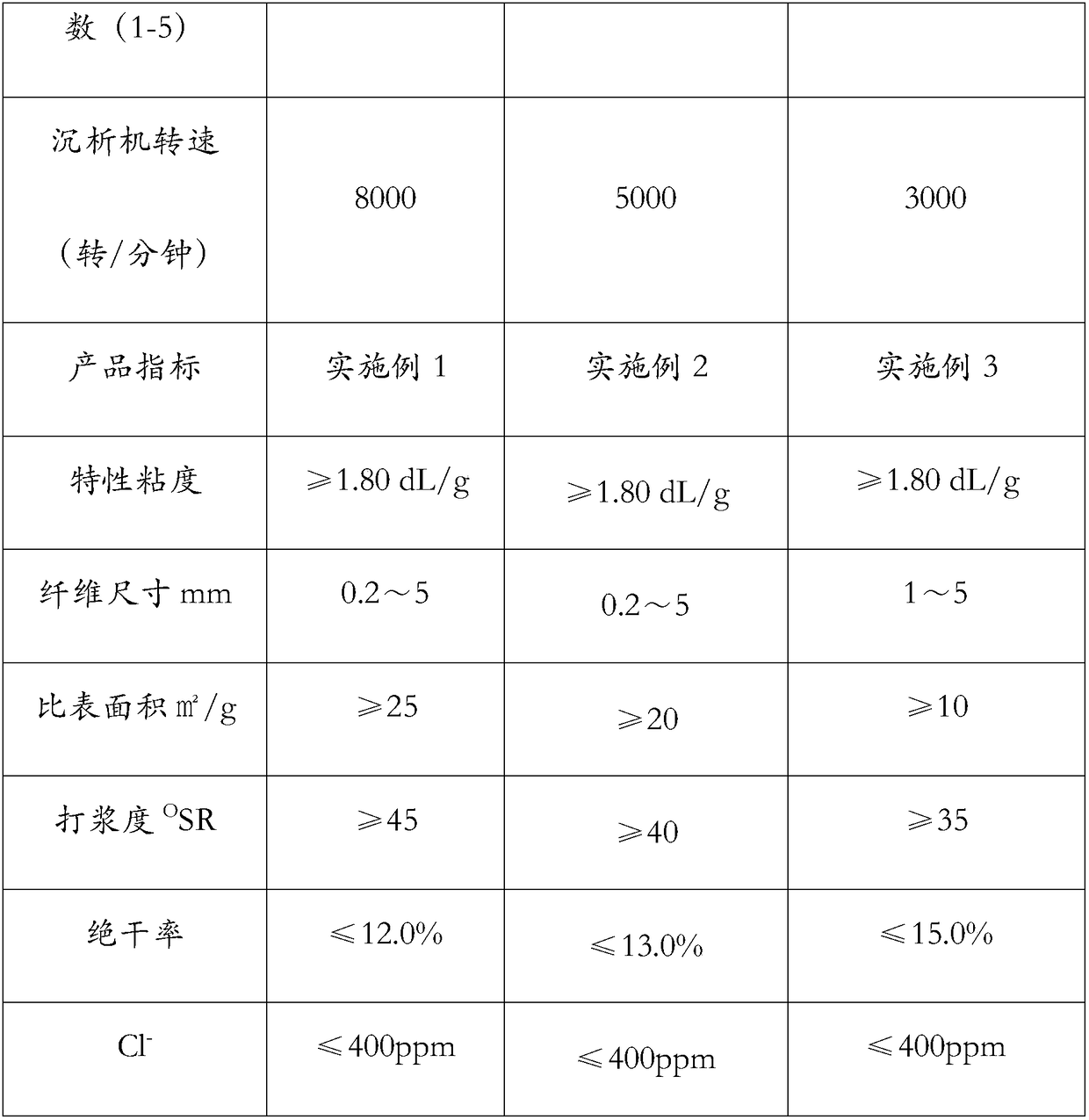

Embodiment 1

[0028] (1) Preparation of resin solution: DMAC in molar ratio: m-phenylenediamine: isophthaloyl dichloride=15: 1: 1 gets the raw materials ready, gets the solvent DMAC 570Kg to be used after the solvent preparation kettle cools down and transfers to the polymerization reactor and stirs evenly At the same time, open the jacket and freeze the brine to cool down, add 47.17kg of m-phenylenediamine to completely dissolve, keep the temperature ≤ -5°C, add a total of 88.55kg of isophthaloyl chloride in batches, and polycondensate to form a polymer resin solution; control the intrinsic viscosity of the solution : ≥1.8dL / g, resin content 14.72wt%.

[0029] (2) Resin solution neutralization: prepare materials according to the molar ratio of lithium chloride / m-phenylenediamine=2.0, transfer the polymeric resin solution to the neutralization kettle, keep stirring, and drop 20.91kg of powdery lithium hydroxide into the aramid resin solution HCl undergoes a neutralization reaction until it ...

Embodiment 2

[0038] (1) Preparation of resin solution: DMAC in molar ratio: m-phenylenediamine: isophthaloyl dichloride=15: 1: 1 gets the raw materials ready, gets the solvent DMAC 570Kg to be used after the solvent preparation kettle cools down and transfers to the polymerization reactor and stirs evenly At the same time, open the jacket and freeze the brine to cool down, add 47.17kg of m-phenylenediamine to completely dissolve, keep the temperature ≤ -5°C, add a total of 88.55kg of isophthaloyl chloride in batches, and polycondensate to form a polymer resin solution; control the intrinsic viscosity of the solution : ≥1.8dL / g, resin content 14.72wt%.

[0039] (2) Resin solution neutralization: prepare materials according to the molar ratio of lithium chloride / m-phenylenediamine=2.0, transfer the polymeric resin solution to the neutralization kettle, keep stirring, and drop 20.91kg of powdery lithium hydroxide into the aramid resin solution HCl undergoes a neutralization reaction until it ...

Embodiment 3

[0048] (1) Preparation of resin solution: DMAC in molar ratio: m-phenylenediamine: isophthaloyl dichloride=15: 1: 1 gets the raw materials ready, gets the solvent DMAC 570Kg to be used after the solvent preparation kettle cools down and transfers to the polymerization reactor and stirs evenly At the same time, open the jacket and freeze the brine to cool down, add 47.17kg of m-phenylenediamine to completely dissolve, keep the temperature ≤ -5°C, add a total of 88.55kg of isophthaloyl chloride in batches, and polycondensate to form a polymer resin solution; control the intrinsic viscosity of the solution : ≥1.8dL / g, resin content 14.72wt%.

[0049] (2) Resin solution neutralization: prepare materials according to the molar ratio of lithium chloride / m-phenylenediamine=2.0, transfer the polymeric resin solution to the neutralization kettle, keep stirring, and drop 20.91kg of powdery lithium hydroxide into the aramid resin solution HCl undergoes a neutralization reaction until it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com