Nitridation loosening layer heat treatment method capable of controlling ion nitriding formation effectively

A heat treatment method, ion nitriding technology, applied in the direction of coating, solid diffusion coating, metal material coating technology, etc., can solve the problem of reducing the surface hardness and wear resistance of 42CrMo nitrided layer, affecting the contact fatigue strength of 42CrMo, reducing Surface roughness and other issues, to achieve the effect of increasing surface free energy, increasing hardness, and improving the level of nitrided porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

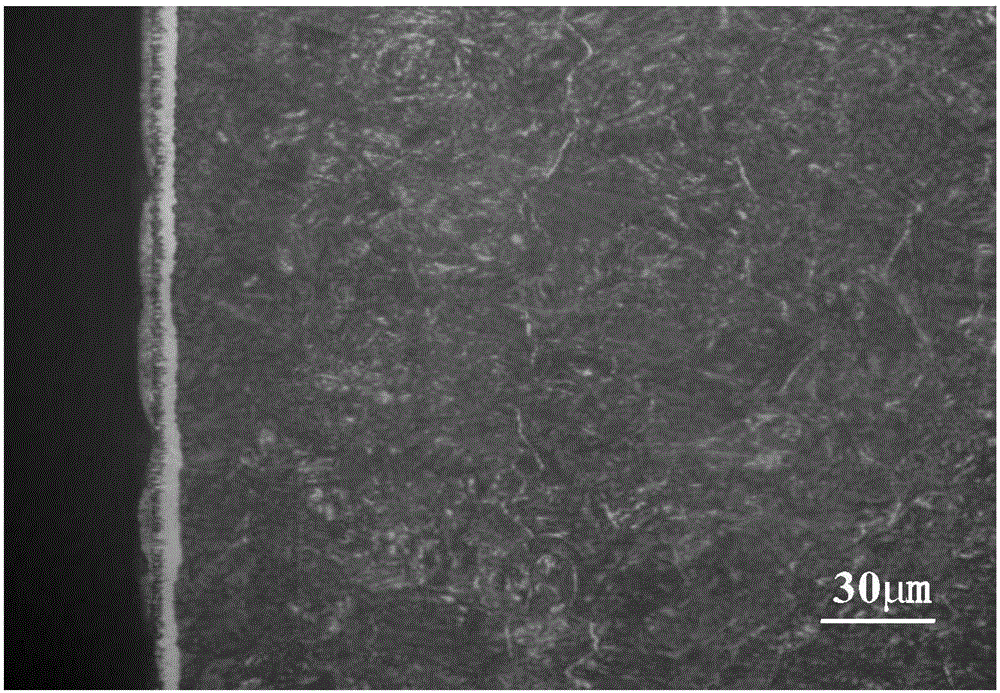

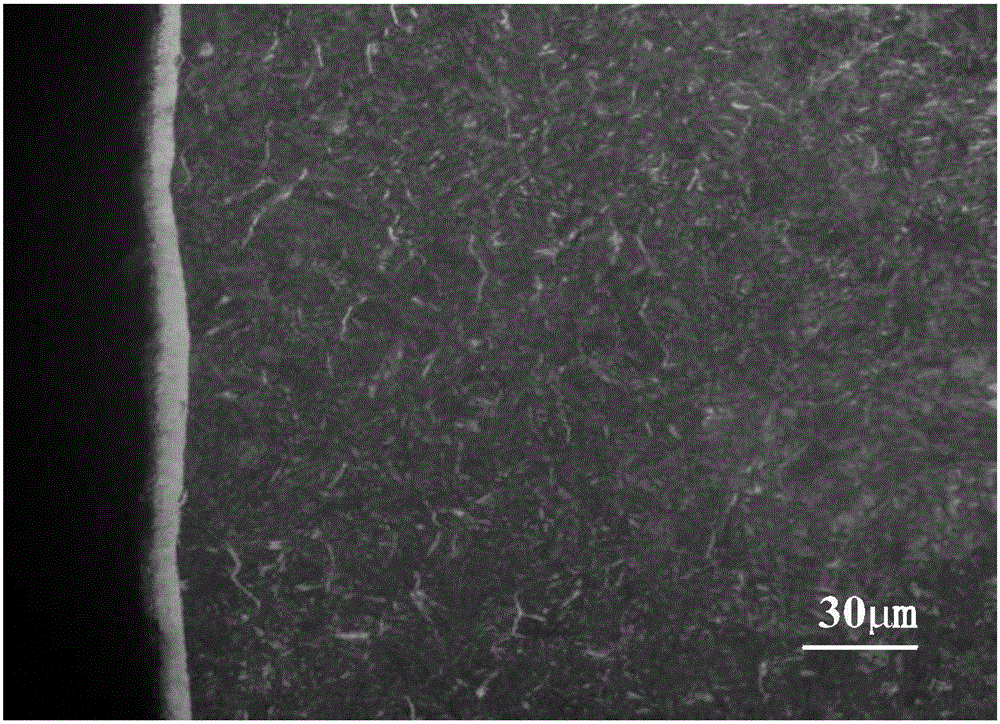

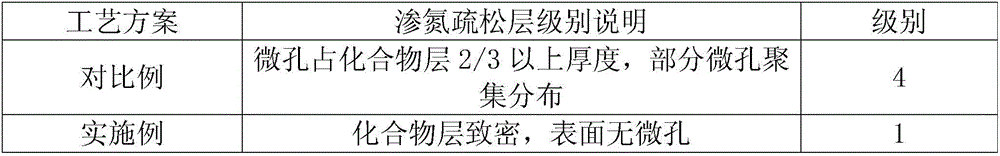

Image

Examples

Embodiment

[0023] Put the 42CrMo gear into the ion nitriding furnace, evacuate it to less than 10Pa, adjust the voltage to the maximum value, slowly adjust the current value until it starts to glow, and then pass in hydrogen for ion sputtering for 10 minutes, continue to pass in nitrogen, and adjust the balance of nitrogen and hydrogen. Flow ratio is 1:3, continue to heat up.

[0024] When the temperature rises to the oxidation temperature of 350°C, close the nitrogen and hydrogen valves, and let air flow in at 4L / min, the atmosphere pressure in the furnace is 100Pa, and the holding time is 0.5h.

[0025] Close the air valve, open the nitrogen and hydrogen valves, adjust the flow ratio of nitrogen and hydrogen to 1:3, continue to heat up, and start timing when the temperature reaches the nitriding temperature of 560°C for ion nitriding. The nitriding atmosphere pressure is 350Pa, and the holding time for 10h.

[0026] After ion nitriding, close the nitrogen and hydrogen valves. After t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com