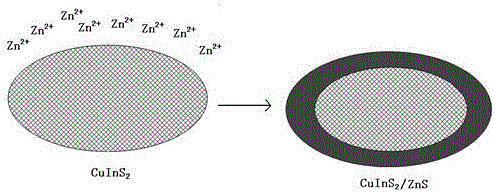

CuInS2/ZnS core-shell quantum dots and preparation method thereof

A core-shell quantum dot and quantum dot technology, applied in the field of CuInS2/ZnS core-shell quantum dots and their preparation, can solve the problems of complex synthesis and purification process, low controllability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Red luminescent CuInS 2 The preparation steps of / ZnS core-shell quantum dots are as follows:

[0034](1) Preparation of zinc precursor: 60 mg of zinc oxide and 5 mL of oleic acid (Oleicacid) were mixed and heated at 250 °C under an inert gas atmosphere until the zinc oxide was completely dissolved, and then 3 g of octadecene ( 1-octadecene), to obtain the Zn-Zn precursor.

[0035] (2) Preparation of CuInS by cation exchange method 2 / ZnS core-shell quantum dots: In an inert gas atmosphere, the temperature of the zinc precursor was rapidly raised to 220 °C, and then 400 μL of CuInS with a luminescence peak of 590 nm 2 The octadecene (1-Ocatadecene) solution (1 μM) of quantum dots was injected into the zinc precursor and reacted for 75 mins to obtain CuInS 2 / ZnS core-shell quantum dots, and then remove the heating mantle; after the reaction solution is cooled to room temperature, the product is repeatedly dissolved and precipitated with toluene and anhydrous methanol...

Embodiment 2

[0037] Near-infrared Luminescent CuInS 2 The preparation steps of / ZnS core-shell quantum dots are as follows:

[0038] (1) Preparation of zinc precursor: 60 mg of zinc oxide and 7 mL of fatty acid (Stearic acid) were mixed and heated at 250 °C under an inert gas atmosphere until the zinc oxide was completely dissolved, and then 3 g of octadecene ( 1-octadecene), to obtain the zinc precursor.

[0039] (3) Preparation of CuInS by cation exchange method 2 / ZnS core-shell quantum dots: In an inert gas atmosphere, the temperature of the zinc precursor was rapidly raised to 250 °C, and then 200 μL of CuInS with an emission peak of 810 nm 2 The octadecene (1-Ocatadecene) solution (1 μM) of quantum dots was injected into the zinc precursor and reacted for 60 mins to obtain CuInS 2 / ZnS core-shell quantum dots, and then remove the heating mantle; after the reaction solution is cooled to room temperature, the product is repeatedly dissolved and precipitated with toluene and anhydrou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com