A kind of anti-oxidation coating of electrolytic aluminum prebaked anode and preparation method thereof

A technology of anti-oxidation coating and pre-baked anode, applied in coating and other directions, can solve the problems of short service life and high iron content, and achieve the effect of preventing oxidation peeling, stable properties, and reducing gross and net consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

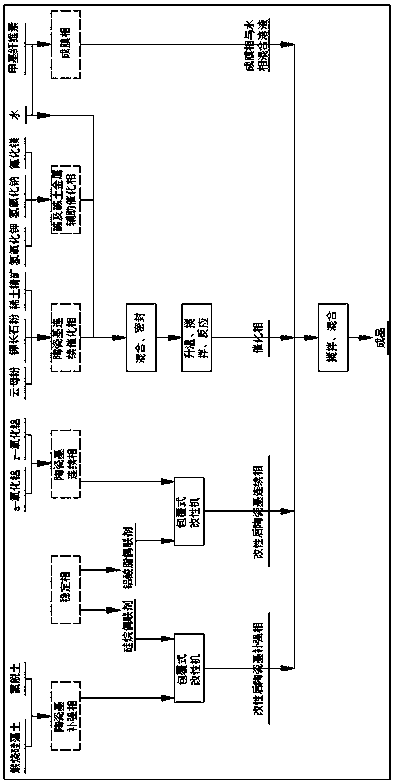

Method used

Image

Examples

Embodiment 1

[0027] 1000kg of electrolytic aluminum prebaked anodic anti-oxidation coating, its components are:

[0028] Ceramic-based continuous phase: composed of α-Al2O3 and γ-Al2O3, accounting for 35% of the total mass of the coating, a total of 350kg, of which α-Al2O3 accounts for 90% of the ceramic-based continuous phase, which is 315kg; 10% of the continuous phase, that is 35kg;

[0029] Ceramic-based continuous catalytic phase: composed of mica powder, potassium feldspar powder, and rare earth concentrate brown yttrium-niobium ore, accounting for 30% of the total mass of the coating, that is, 300kg, of which the amount of mica powder is 40% of the ceramic-based continuous catalytic phase, that is, 120kg , the amount of potassium feldspar powder is 59.67% of the ceramic-based continuous catalytic phase, about 179kg, and the amount of rare earth concentrate brown yttrium-niobium ore is 0.33% of the ceramic-based continuous catalytic phase, about 1kg;

[0030] Alkali and alkaline ear...

Embodiment 2

[0042] 1000kg of electrolytic aluminum prebaked anodic anti-oxidation coating, its components are:

[0043] Ceramic-based continuous phase: composed of α-Al2O3 and γ-Al2O3, accounting for 40% of the total mass of the coating, a total of 400kg, of which 1000 mesh α-Al2O3 accounts for 85% of the ceramic-based continuous phase, which is 340kg; 325 mesh γ-Al2O3 It accounts for 15% of the continuous phase of the ceramic base, that is, 60kg;

[0044] Ceramic-based continuous catalytic phase: composed of mica powder, potassium feldspar powder, and rare earth concentrate brown yttrium-niobium ore, accounting for 20% of the total mass of the coating, that is, 200kg, of which the amount of mica powder is 55% of the ceramic-based continuous catalytic phase, that is, 110kg , the amount of potassium feldspar powder is 44.67% of the ceramic-based continuous catalytic phase, about 89.34kg, and the amount of rare earth concentrate brown yttrium-niobium ore is 0.33% of the ceramic-based contin...

Embodiment 3

[0057] 1000kg of electrolytic aluminum prebaked anodic anti-oxidation coating, its components are:

[0058] Ceramic-based continuous phase: composed of α-Al2O3 and γ-Al2O3, accounting for 25% of the total mass of the coating, a total of 250kg, of which 1000 mesh α-Al2O3 accounts for 100% of the ceramic-based continuous phase, which is 250kg; 325 mesh γ-Al2O3 It accounts for 0% of the continuous phase of the ceramic base, that is, 0kg;

[0059] Ceramic-based continuous catalytic phase: composed of mica powder, potassium feldspar powder, and rare earth concentrate brown yttrium-niobium ore, accounting for 40% of the total mass of the coating, that is, 400kg, of which the amount of mica powder is 50% of the ceramic-based continuous catalytic phase, that is, 200kg , the amount of potassium feldspar powder is 49.67% of the ceramic-based continuous catalytic phase, about 198.68kg, and the amount of rare earth concentrate brown yttrium-niobium ore is 0.33% of the ceramic-based contin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com