Novel reactive power consumption structure optimization device for anode carbon block of electrolytic cell

An anode carbon block and electrolytic cell technology, which is applied to the carbon field of aluminum electrolysis, can solve the problems of increasing resistance, reducing the gross consumption of carbon blocks, wasting power consumption, etc., so as to reduce gross consumption, reduce pollution and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

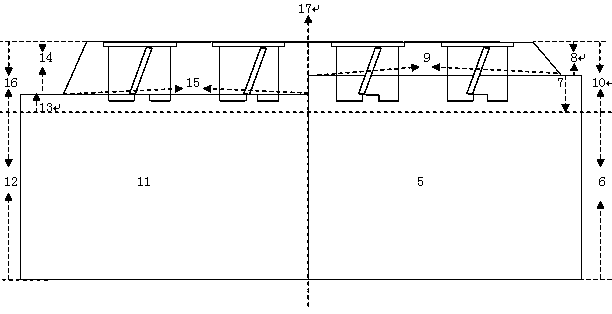

[0010] like figure 2 Shown: A new structure optimization device for the reactive power consumption of the anode carbon block in the electrolytic cell, which optimizes the structure of the boss and the carbon block between the top and bottom of the anode carbon block 170mm ( figure 2 16 in), the height of the boss is changed from the original 70mm ( figure 2 8) optimized to 140mm ( figure 2 13 in), the anode carbon block under the boss is 100mm ( figure 2 7) optimized to 30mm ( figure 2 12 in), the width of the lower side of the boss is 600mm ( figure 2 9) reduced to 480mm ( figure 2 14), the anode density is changed from the original 1.58 g / cm 3 Increased to 1.62 g / cm 3 .

[0011] The boss and carbon block structure between the anode carbon block 170mm from top to bottom is the height of the reactive power consumption of the anode carbon block, which is called the height of the residual electrode by electrolytic workers, and is also the height of the structural ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com