Electrolytic aluminum anode capable of inhibiting deformation of steel claws

A technology for electrolytic aluminum and steel claws, applied in the field of anodes for electrolytic aluminum, can solve the problems of high investment cost of one-time equipment, large power consumption for equipment operation, and increase of staff, etc., so as to increase equipment investment, increase energy consumption, increase The effect of the staff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

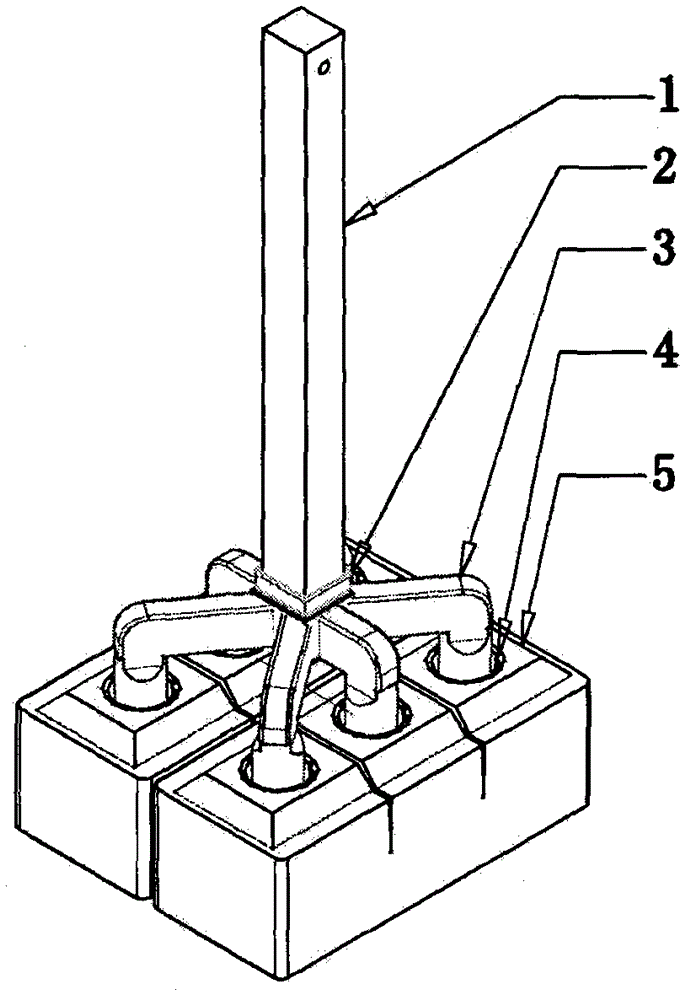

[0013] Such as figure 1 As shown, the anode for electrolytic aluminum that can suppress the deformation of steel claws includes an anode guide rod 1, a plurality of steel claws 3 connected to the lower end of the anode guide rod, an explosion welding block 2, cast phosphorus iron 4 and an anode carbon block 5; Rod 1, steel claw 3, and explosive welding block 1 form an anode guide rod group. There are a plurality of carbon bowls 51 on the upper end face of the anode carbon block 5, the number of the steel claws 3 corresponds to the number of the carbon bowls, and a plurality of steel claws 3 are respectively inserted into the carbon bowls 51 on the anode carbon block 5 and used Casting ferrophosphorus 4 and anode carbon block 5 are fixed together.

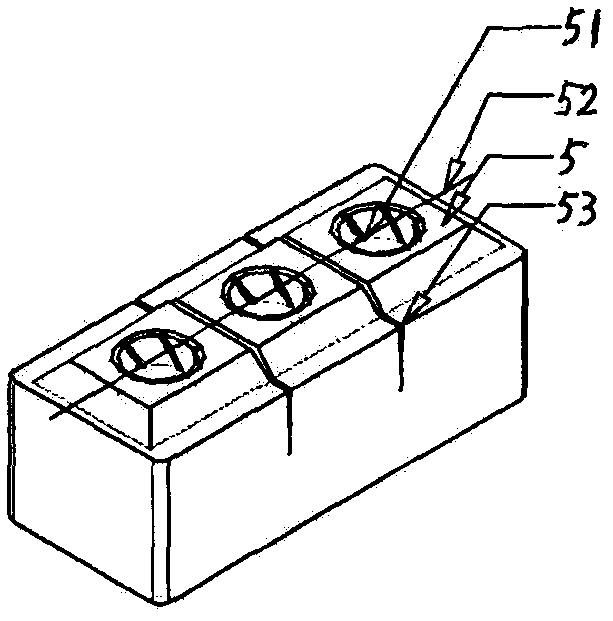

[0014] Such as figure 2 As shown, a pre-separation groove 53 is opened between adjacent carbon bowls 51 on the upper end surface of the anode carbon block 5 . The pre-separation groove 53 is a straight groove or a curved groove....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com