Method for reducing anode gross dissipation of prebaked aluminum electrolysis cell

An aluminum electrolytic cell and anode technology, which is applied in the field of pre-baked aluminum electrolytic cells, can solve the problems of increasing anode gross consumption and ineffective utilization of carbon block residues, and achieves the advantages of reducing anode gross consumption, reducing energy consumption and improving current efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

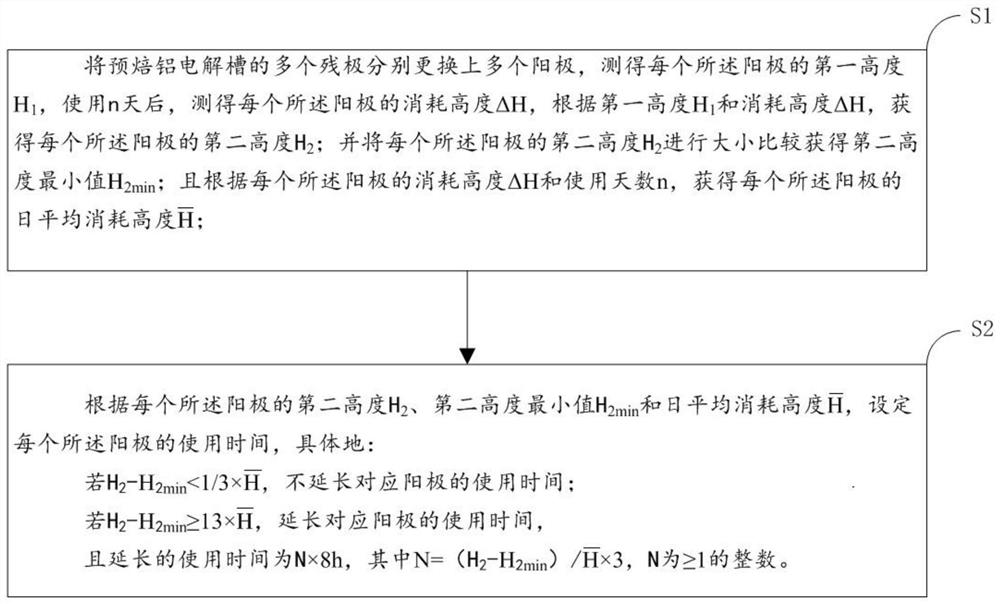

Method used

Image

Examples

Embodiment 1

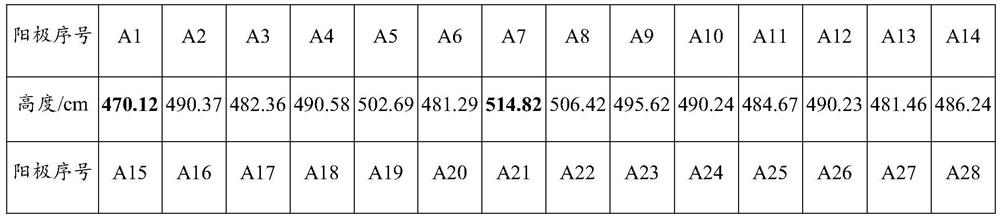

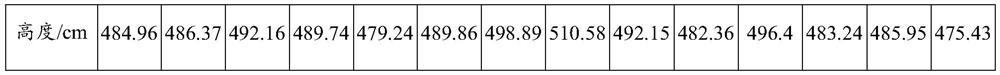

[0057] S1. A 200kA electrolytic cell uses an anode replacement system to perform anode replacement and anode data testing for one cycle, in which the total number of anode carbon blocks is 28, and the first height h of each anode is measured 1 ; After the butt electrode of the prebaked aluminum electrolytic cell was replaced with the 28 anodes and used for m days, the consumption height Δh of each anode in one cycle of each anode was measured, as shown in Table 1.

[0058] Table 1 - Each Anode A i Consumption height Δh of carbon block in one cycle

[0059]

[0060]

[0061] The minimum value of consumption height h in one cycle min For the A1 anode is 470.12cm, the maximum consumption height h in one cycle max The A7 anode is 514.82cm.

[0062] A covering material is obtained, the particle size composition of the covering material is 35±1% by mass fraction with a particle diameter less than 0.25mm, and the maximum particle diameter is 15mm. According to the consumpti...

Embodiment 2

[0087] S1. A 300kA electrolytic cell uses an anode replacement system to perform anode replacement and anode data testing for 3 cycles, in which the total number of anode carbon blocks is 40, and the first height h of each anode is measured 1 ; After the butt of the prebaked aluminum electrolytic cell was replaced with the 40 anodes and used for m days, the consumption height Δh of each anode in one cycle of each anode was measured, as shown in Table 7.

[0088] Table 7 - Each Anode A i Consumption height Δh of carbon block in one cycle

[0089]

[0090] The minimum average value of consumption height in a cycle is h min For the A20 anode is 426.46cm, the average consumption height within a cycle is the largest h max The A30 anode is 477.85cm.

[0091] A covering material is obtained, the particle size composition of the covering material is 33±2% by mass fraction with a particle diameter less than 0.25mm, and the maximum particle diameter is 12mm. According to the consum...

Embodiment 3

[0116] S1. A 400kA electrolytic cell uses an anode replacement system to perform anode replacement and anode data testing for 3 cycles, in which the total number of anode carbon blocks is 48, and the first height h of each anode is measured 1 ; After the butt of the prebaked aluminum electrolytic cell was replaced with the 48 anodes and used for m days, the consumption height Δh of each anode in one cycle of each anode was measured, as shown in Table 13.

[0117] Table 13 - Each Anode A i Consumption height Δh of carbon block in one cycle

[0118] Anode serial number A1 A2 A3 A4 A5 A6 A7 A8 A9 A10 A11 A12 Height / cm 417.62 453.79 438.37 461.84 440.75 450.59 453.12 448.03 449.66 439.68 454.23 467.26 Anode serial number A13 A14 A15 A16 A17 A18 A19 A20 A21 A22 A23 A24 Height / cm 461.9 443.89 455.91 444.52 442.42 443.85 449.54 448.6 447.27 436.78 447.52 423.69 Anode serial number A25 A26 A27 A28 A29 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com