A method for preparing a superhydrophobic coating with self-bounce properties of condensed droplets

A super-hydrophobic coating and characteristic technology, applied in coatings, anti-fouling/underwater coatings, anti-corrosion coatings, etc., to achieve broad application prospects, improve anti-condensation effect, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

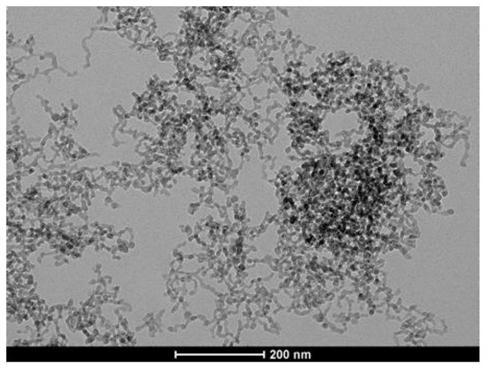

[0033] After mixing 10 mL of aqueous ammonia solution and 20 mL of deionized aqueous solution through ultrasonic dispersion for 5 minutes, add 2 g of acidic chain aqueous silica sol (pH=2-4, diameter 9-15nm, chain length 40-100nm, dioxide The weight concentration of silicon is 10-20%), and a clear mixed solution is obtained after 5 minutes of ultrasonic dispersion. Add the above mixed solution dropwise to 200mL of absolute ethanol solution, sonicate for 5 minutes and then mechanically stir for 5 minutes, then add 1mL of tetraethylorthosilicate solution dropwise, continue mechanical stirring for 60 minutes, and then add 0.5mL dropwise The superhydrophobic coating is obtained after 12 hours of continuous mechanical stirring, and the chain nano-silica after hydrophobic modification still maintains the chain structure. figure 1 It is a transmission electron micrograph of the coating.

Embodiment 2

[0035] Add 2g of acidic chain aqueous silica sol (pH=2-4, diameter 9-15nm, chain length 40-100nm, silica weight concentration 10-20%) dropwise into 200mL of absolute ethanol solution, ultrasonic After 10 minutes of mechanical stirring for 10 minutes, the mixed solution began to appear darker in color. Then 1mL of tetraethylorthosilicate solution was added dropwise, and after mechanical stirring for 60 minutes, 0.5mL of perfluorosilane was added dropwise, and finally mechanical stirring was continued for 12 hours. The obtained superhydrophobic coating appeared white suspension emulsion, gel Or the reunion is obvious. And add 1g of alkaline chain type aqueous silica sol (pH=9-11, diameter 9-15nm, chain length 40-100nm, silica weight concentration 30-40%) dropwise to 200mL of absolute ethanol solution After sonicating for 10 minutes, mechanically stirring for 10 minutes, and then adding 1 mL of tetraethyl orthosilicate solution dropwise, after continuing mechanical stirring for 6...

Embodiment 3

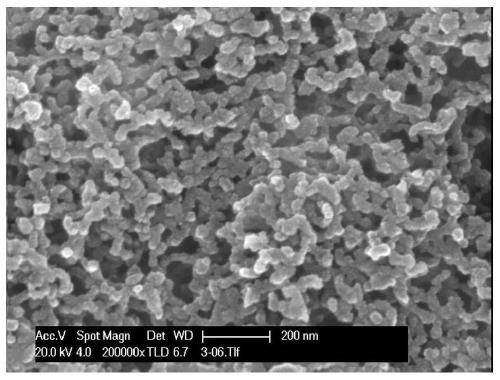

[0037] After mixing 12 mL of aqueous ammonia solution and 24 mL of deionized aqueous solution through ultrasonic dispersion for 5 minutes, add 3 g of chain aqueous silica sol (pH=2-4, diameter 9-15nm, chain length 40-100nm, silica The weight concentration is 10-20%), and a clear mixed solution is obtained after ultrasonic dispersion for 10 minutes. Add the above mixed solution dropwise to 220mL of isopropanol solution, sonicate for 10 minutes and then mechanically stir for 10 minutes, then add 2mL of tetraethylorthosilicate solution dropwise, continue mechanical stirring for 15 minutes, and then add 2mL of Perfluorosilane, the superhydrophobic coating is obtained after 48 hours of continuous mechanical stirring. The coating is immersed and coated on the surface of the clean glass substrate to obtain a nanoporous superhydrophobic coating. figure 2 The scanning electron micrograph of the coating. Among them, the dipping coating process is: dipping time 60s, dipping pulling speed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com