Filling material of car cushion and preparation method of filling material

The technology of filling material and car seat cushion is applied in the field of filling material of car seat cushion and its preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

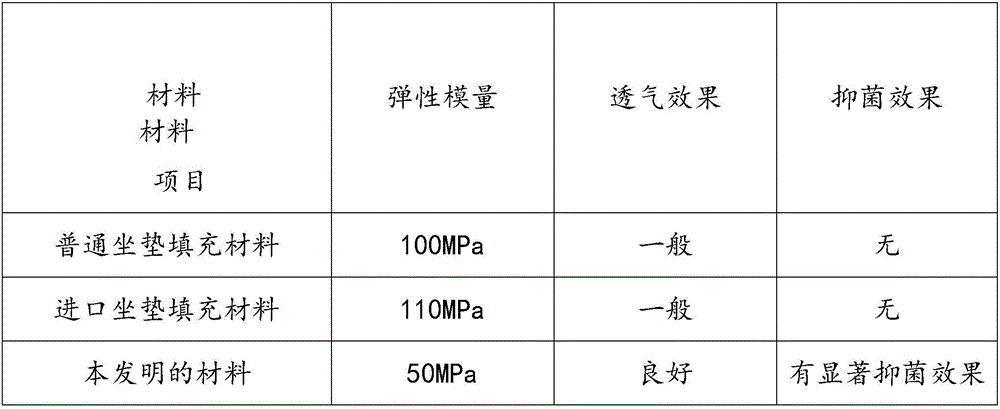

Image

Examples

Embodiment 1

[0018] A filling material for a car seat cushion, made of the following materials in parts by weight, including 68 parts of hemp fiber, 48 parts of coconut palm fiber, 25 parts of absorbent cotton, natural latex 4 parts, 16 parts of nano-calcium carbonate, 7 parts of nano-activated carbon, 4 parts of nano-silver, 9 parts of low-density polyethylene, 25 parts of epoxy resin, 4 parts of polypropylene, 11 parts of magnesium carbonate, 12 parts of sodium bicarbonate, trichlor 6 parts of fluoromethane, 12 parts of sodium lauryl sulfate, 18 parts of polyacrylonitrile, 22 parts of polyamide, 9 parts of acetate fiber and 22 parts of cupro ammonia fiber.

[0019] A preparation method of a filling material for an automobile seat cushion, comprising the following steps:

[0020] 1) Put 68 parts of hemp fiber, 48 parts of coconut palm fiber, 25 parts of absorbent cotton, 4 parts of natural latex, 16 parts of nano-calcium carbonate, 7 parts of nano-activated carbon, and 4 parts of nano-sil...

Embodiment 2

[0026] A filling material for a car seat cushion, made of the following materials in parts by weight, including 69 parts of hemp fiber, 51.5 parts of coconut palm fiber, 30 parts of absorbent cotton, natural latex 6 parts, 19 parts of nano-calcium carbonate, 9 parts of nano-activated carbon, 6 parts of nano-silver, 12.5 parts of low-density polyethylene, 27.5 parts of epoxy resin, 6.5 parts of polypropylene, 12.5 parts of magnesium carbonate, 13.5 parts of sodium bicarbonate, trichloride 8 parts of fluoromethane, 13 parts of sodium lauryl sulfate, 19 parts of polyacrylonitrile, 23.5 parts of polyamide, 12 parts of acetate fiber and 23 parts of cupro ammonia fiber.

[0027] A preparation method of a filling material for an automobile seat cushion, comprising the following steps:

[0028] 1) Put 69 parts of hemp fiber, 51.5 parts of coconut palm fiber, 30 parts of absorbent cotton, 6 parts of natural latex, 19 parts of nano-calcium carbonate, 9 parts of nano-activated carbon, an...

Embodiment 3

[0034]A filling material for a car seat cushion, made of the following materials in parts by weight, including 70 parts of hemp fiber, 55 parts of coconut palm fiber, 35 parts of absorbent cotton, natural latex 8 parts, 22 parts of nano-calcium carbonate, 11 parts of nano-activated carbon, 8 parts of nano-silver, 16 parts of low-density polyethylene, 30 parts of epoxy resin, 9 parts of polypropylene, 14 parts of magnesium carbonate, 15 parts of sodium bicarbonate, trichloride 10 parts of fluoromethane, 14 parts of sodium lauryl sulfate, 20 parts of polyacrylonitrile, 25 parts of polyamide, 15 parts of acetate fiber and 24 parts of cupro ammonia fiber.

[0035] A preparation method for a filling material of an automobile seat cushion, comprising the following steps:

[0036] 1) Put 70 parts of hemp fiber, 55 parts of coconut palm fiber, 35 parts of absorbent cotton, 8 parts of natural latex, 22 parts of nano-calcium carbonate, 11 parts of nano-activated carbon, and 8 parts of n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com