Preparation method of mercapto functionalized lignin microspheres

A lignin, functionalized technology, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve the problem of uneven particle size of lignin microspheres, lack of effective functional groups, The problem of poor controllability of morphology, etc., achieves good industrial application prospects, uniform particle size, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

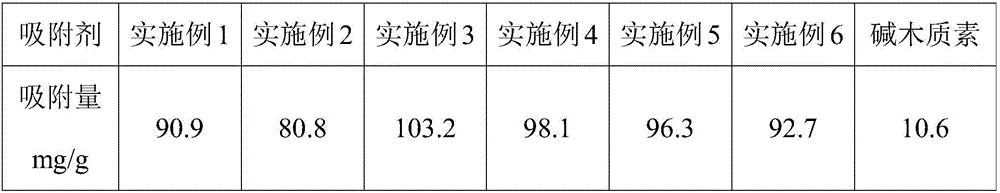

Examples

Embodiment 1

[0028] A preparation method of mercapto-functionalized lignin microspheres, comprising the following steps:

[0029] (1) Construct the oil-in-water-in-oil double emulsion droplet system by microchannel reactor (this microchannel reactor is the focused flow microchannel reactor): comprise the following steps:

[0030] a. dissolving ethylene dichloride in sherwood oil to prepare an organic solution with a mass fraction of 10%, while adding 3% catalyst aluminum chloride as the internal phase;

[0031] b. Add ethanol lignin to water to prepare an aqueous solution with a solid content of 16%, and add 5% emulsifier and 6% regulator sodium carboxymethylcellulose. The emulsifier is SDBS and OP-15, SDBS and OP-15 The mass ratio of the mixture is 1:1, and the mixture is evenly used as the intermediate phase;

[0032] c. Add surfactants Tween80 and Span60 (the mass ratio of Tween80 and Span60 is 2:1) into dodecane, and prepare an organic solution containing surfactant mass percentage co...

Embodiment 2

[0038] A preparation method of mercapto-functionalized lignin microspheres, comprising the following steps:

[0039] (1) Construct the oil-in-water-in-oil double emulsion droplet system by microchannel reactor (this microchannel reactor is the focused flow microchannel reactor): comprise the following steps:

[0040]a. dissolving ethylene dichloride in benzene to prepare an organic solution with a mass fraction of 15%, while adding 4% catalyst aluminum chloride as the internal phase;

[0041] b. Add lignosulfonate to water to prepare an aqueous solution with a solid content of 21%, and add 7% emulsifier and 7.5% regulator water-soluble starch. The emulsifier is SDS and OP-10, and SDS and OP-10 are mixed The ratio is 1:1, mixed evenly as the intermediate phase;

[0042] c. Add surfactants Span80 and Tween20 (the mixing ratio of Span80 and Tween20 is 1:1) into n-hexane, and prepare an organic solution containing a surfactant mass percentage concentration of 6.5% as the external...

Embodiment 3

[0048] A preparation method of mercapto-functionalized lignin microspheres, comprising the following steps:

[0049] (1) Construct the oil-in-water-in-oil double emulsion droplet system by microchannel reactor (this microchannel reactor is the focused flow microchannel reactor): comprise the following steps:

[0050] a. dissolving ethylene dichloride in ether is prepared as an organic solution with a mass fraction of 2%, while adding 1% catalyst aluminum chloride as the internal phase;

[0051] b. adding alkali lignin to water to prepare an aqueous solution with a solid content of 5%, and adding 1% emulsifier SDS and 2% regulator polyethylene glycol, and mixing uniformly as an intermediate phase;

[0052] c. adding the surfactant Span80 into the liquid paraffin, and preparing an organic solution containing a surfactant mass percentage concentration of 1% as the external phase;

[0053] d. Make the internal phase and the intermediate phase flow into the focused flow microchann...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com