Method for preparing polyaniline

A technology of polyaniline and aniline, which is applied in the field of large-scale preparation of polyaniline, can solve the problems of environmental pollution, unfavorable scale production, high production cost, etc., and achieve the effect of increasing the output per unit volume, increasing the content, and being easy to realize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

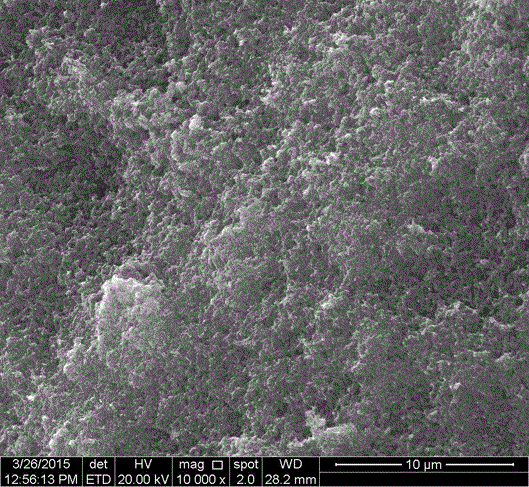

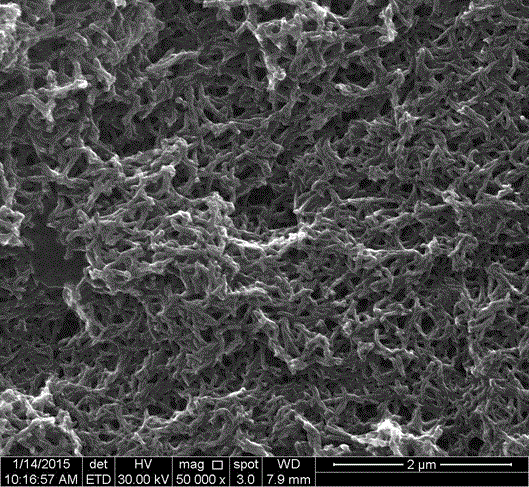

[0028] Dissolve aniline in ethanol to form 1 mol / L solution A; dissolve ammonium persulfate in 1 mol / L hydrochloric acid to form solution B; quickly pour solution B into 1 L according to aniline / ammonium persulfate=1 / 2 In solution A, stir mechanically at 400 r / min at 5°C for 30 minutes, then filter with suction, wash the filter residue with ethanol until it is colorless, wash it with deionized water until it is neutral or close to neutral, and dry it in vacuum at 80°C for 24 h , and then take it out and put it in a desiccator to obtain 92 g of fibrous polyaniline.

Embodiment 2

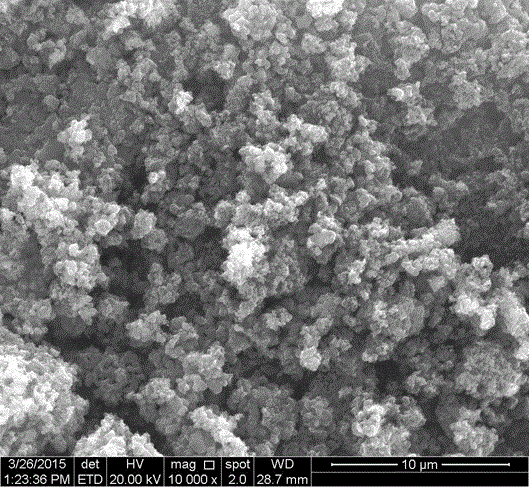

[0030] Dissolve aniline in acetone to form 2 mol / L solution A; dissolve ammonium persulfate in 1 mol / L sulfuric acid to form solution B; quickly pour solution B into 1 L according to aniline / ammonium persulfate=1 / 4 In solution A, stir mechanically at 400 r / min at 5°C for 30 minutes, then filter with suction, wash the filter residue with ethanol until it is colorless, wash it with deionized water until it is neutral or close to neutral, and dry it in vacuum at 80°C for 24 h , then take it out and put it in a desiccator to get 185 g of granular polyaniline.

Embodiment 3

[0032] Dissolve aniline in ethylene glycol to form 0.5 mol / L solution A; dissolve hydrogen peroxide in 0.5 mol / L hydrochloric acid to form solution B; quickly pour solution B into 1 L of solution A according to aniline / hydrogen peroxide = 1 / 1 After ultrasonication for 60 min at 5°C, filter with suction, wash the filter residue with acetone until it is colorless, wash it with deionized water until it is neutral or nearly neutral, dry it in vacuum at 95°C for 8 h, take it out, put it in In a desiccator, 41.3 g of rod-shaped polyaniline was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com