Preparation of protein solid-phase alkylation reagent, and solid-phase alkylation reagent and applications thereof

An alkylation reagent and solid-phase alkane technology, applied in the field of protein solid-phase alkylation reagents, can solve the problems of difficult to achieve deep coverage analysis of proteome, difficult to remove, unable to use strong protein extraction reagents, etc. The effect of flux, improving hydrophilicity, and shortening modification time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

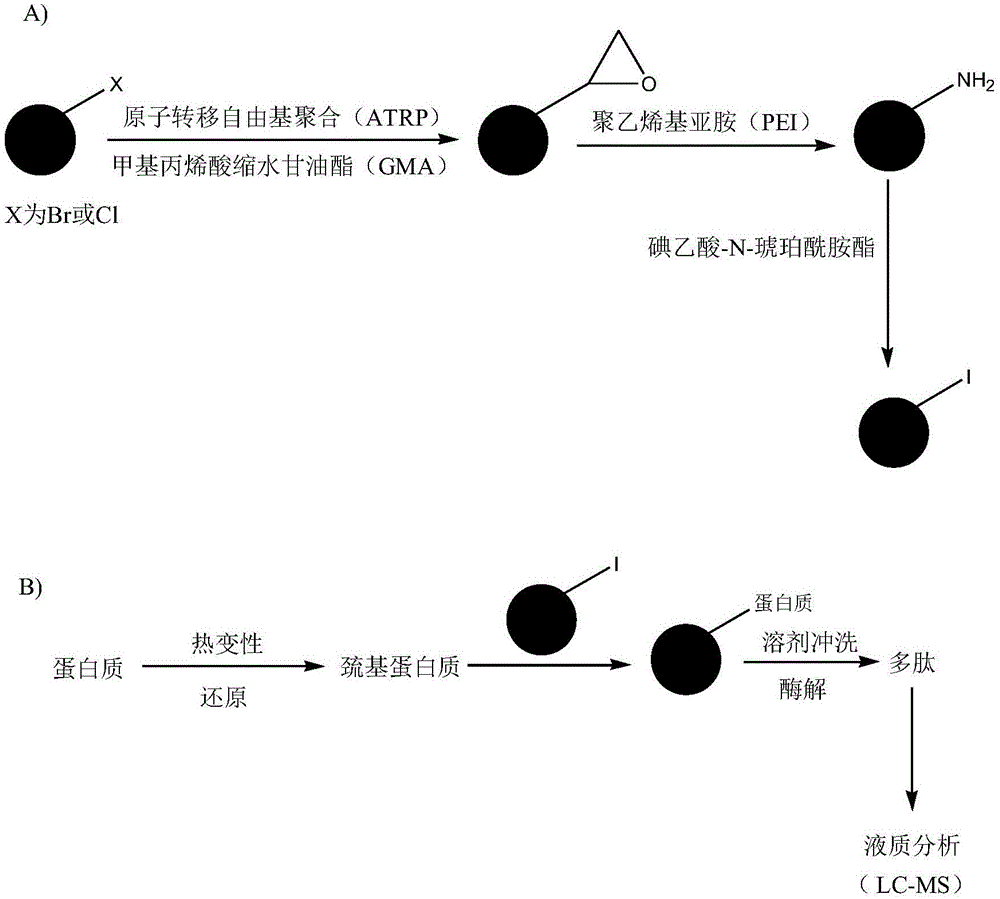

[0027] 1. Modification of ATRP initiator: Weigh 4g of silica gel, add 60mL of toluene and 1.2mL of 3-(trimethoxysilylpropyl)-2-bromo-2-methylpropyl ester, mix well, stir and reflux for 90 ℃ reaction 12h. After the reaction was completed, it was washed 3 times with absolute ethanol.

[0028] 2. Modification of epoxy groups: Weigh 1.2g of silica gel particles modified with ATRP initiator, add 28mL methanol, 2.65mL glycidyl methacrylate (GMA), 0.0314mL N,N,N',N",N "'-Pentamethyldiethylenetriamine, after mixing, add 10mg CuCl and 1.7mg CuCl after passing nitrogen gas for 5min 2 , Sealed and refluxed at 60°C for 6h to prepare Si-GMA particles. After the reaction is completed, wash with methanol and water three times respectively, then add supersaturated EDTA solution to wash until colorless, then wash with water and methanol, and dry it for later use.

[0029] 3. PEI modification: Disperse the prepared Si-GMA particles in 50mM phosphate buffer solution (pH 8.0), add 1.0g PEI to ...

Embodiment 2

[0032] 1. Modification of ATRP initiator: Weigh 10g of silica gel, add 150mL of toluene and 3mL of 3-(trimethoxysilylpropyl)-2-bromo-2-methylpropyl ester, mix well, stir and reflux at 90°C Reaction 12h. After the reaction was completed, it was washed 3 times with absolute ethanol.

[0033] 2. Modification of epoxy groups: Weigh 3g of silica gel particles modified with ATRP initiator, add 50mL methanol, 5mL glycidyl methacrylate (GMA), 0.1mL N,N,N',N",N"' -Pentamethyldiethylenetriamine, after mixing well, add 50mg CuCl and 8.5mg CuCl after flowing nitrogen for 5min 2 , Sealed and refluxed at 60°C for 6h to prepare Si-GMA particles. After the reaction is completed, wash with methanol and water three times respectively, then add supersaturated EDTA solution to wash until colorless, then wash with water and methanol, and dry it for later use.

[0034] 3. PEI modification: Disperse the prepared Si-GMA particles in 50mM phosphate buffer solution (pH 8.0), add 1.0g PEI to a final ...

Embodiment 3

[0037] Other conditions are the same as in Example 1, and the ATRP catalyst becomes FeCl 2 / FeCl 3 , to prepare protein solid-phase alkylation reagent, which is reagent 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com