Chondroitin sulfate extraction method

A chondroitin sulfate and extraction method technology, applied in the field of biological extraction, can solve the problems of water environment pollution, great difficulty in filtration, cumbersome steps, etc., and achieve the effects of improving economic and social benefits, ensuring protein quality, and improving protein quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

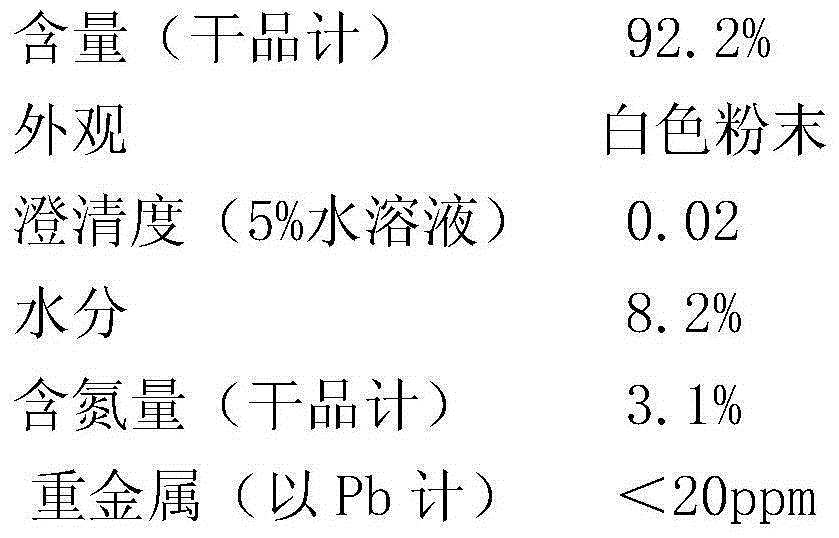

Image

Examples

Embodiment 1

[0021] 1. Wash and crush 100Kg of fresh pork ribs, put them in an enzymatic hydrolysis tank, add 200Kg of demineralized water, adjust the pH of the solution to 8-9 with NaOH or HCl, add 0.2Kg of biological enzyme complex, control the temperature at 50°C and stir Enzymatic hydrolysis for 6 hours. Add NaOH to the above enzymolysis solution to adjust the pH of the solution to 10, heat the material to 80° C. for 20-30 minutes, and filter after heat treatment.

[0022] 2. Add 0.2Kg of protein anti-sedimentation agent to the above filtrate, stir and add edible alcohol 3 times the volume of the filtrate to make the ethanol concentration reach 70%, precipitate chondroitin sulfate, press filter, and separate the crude product of chondroitin sulfate precipitate and protein filtrate.

[0023] 3. Dissolve the crude product of the chondroitin sulfate precipitate with 3 times demineralized water, add 0.02Kg of protein anti-sedimentation agent, add alcohol to make the ethanol concentration ...

Embodiment 2

[0027] 1. 100Kg of dry pig nose cartilage, soaked in tap water for 10 hours, washed and crushed, placed in an enzymatic hydrolysis tank, added 400Kg of demineralized water, adjusted pH of the solution to 8-9 with acid or alkali, added 0.5Kg of biological enzyme complex , control the temperature at 50°C and stir the enzymolysis for 6 hours. Add NaOH to the above enzymolysis solution to adjust the pH of the solution to 10, heat the material to 80° C. for 20-30 minutes, and filter after heat treatment.

[0028] 2. Add 0.5Kg protein anti-sedimentation agent to the above-mentioned filtrate, stir and add edible alcohol with 3 times the volume of the filtrate, precipitate chondroitin sulfate, press filter, and separate the chondroitin sulfate precipitate crude product and protein filtrate.

[0029] 3. Dissolve the crude chondroitin sulfate precipitate in 6 times demineralized water, add 0.06Kg of protein anti-sedimentation agent, add alcohol to precipitate chondroitin sulfate, press ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com