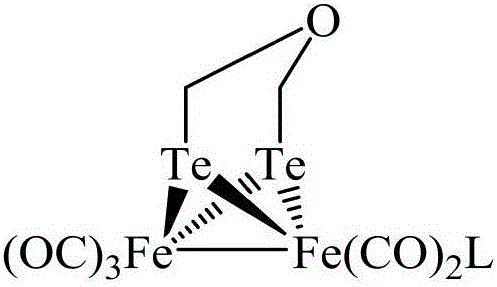

Fe-Fe hydrogenase model compound containing oxa-trimethylene ditelluride bridge and preparation method of model compound

A technology of iron hydrogenase and model substance, which is applied in the fields of iron organic compounds, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc. problem, to achieve the effect of convenient post-processing, high yield and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

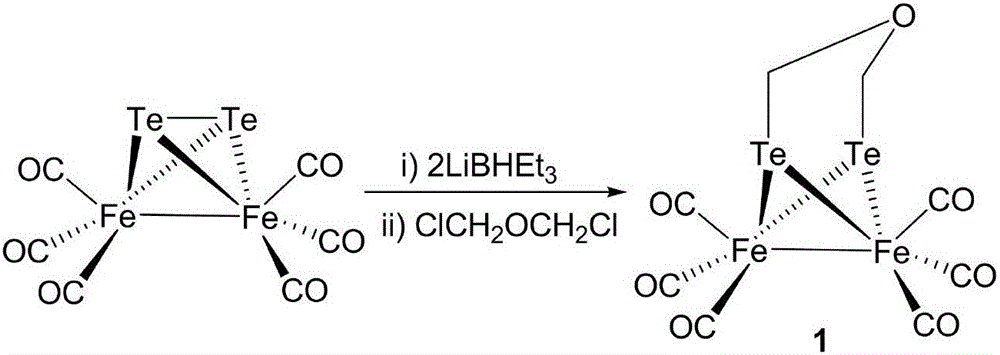

[0018] A method for preparing an iron-iron hydrogenase model substance 1 containing an oxapropylene ditellurium bridge, the chemical formula of the model substance 1 is [(μ-TeCH 2 ) 2 O]Fe 2 (CO) 6 , the preparation process is as follows:

[0019]

[0020] Concrete preparation steps are as follows:

[0021] 1) Under nitrogen protection, add 30mL tetrahydrofuran into a 100mL round-bottomed Schlenk flask equipped with a stirring magnet, cool to -78°C with a liquid nitrogen-acetone bath, and add 0.5mmol (μ-Te) 2 Fe 2 (CO) 6 Petroleum ether solution (20mL) was added in the reaction flask and stirred evenly;

[0022] 2) Add 1mL LiEt to the above system 3 BH (1mol / L in THF), naturally warming up to room temperature;

[0023] 3) Add 90 μL of dichlorodimethyl ether, raise the temperature to 60°C, and react for 12 hours;

[0024] 4) The solvent was removed under reduced pressure, and the product was separated by thin-layer chromatography, using dichloromethane / petroleum eth...

Embodiment 2

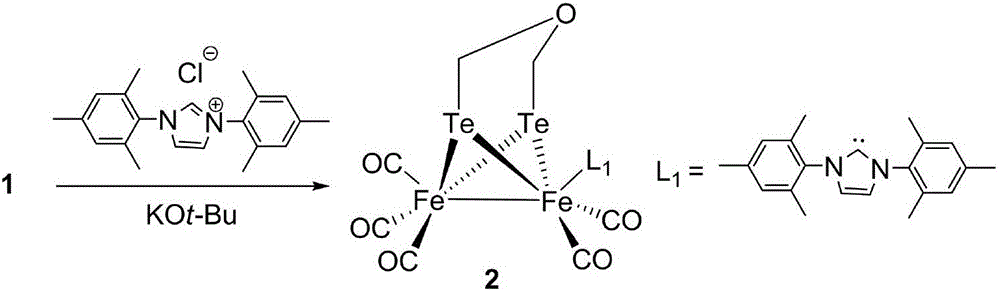

[0027] A method for preparing an iron-iron hydrogenase model substance 2 containing an oxapropylene ditellurium bridge, the chemical formula of the model substance 2 is [(μ-TeCH2 ) 2 O]Fe 2 (CO) 5 (L 1 )[L 1 =1,3-bis(2,4,6-trimethylphenyl)imidazole-2-carbene], the preparation process is as follows:

[0028]

[0029] Concrete preparation steps are as follows:

[0030] 1) Under nitrogen protection, add 269mg (0.79mmol) 1,3-bis(2,4,6-trimethylphenyl)imidazole hydrochloride and 20mL tetrahydrofuran to a 100mL round-bottomed Schlenk flask equipped with a stirring magnet ;

[0031] 2) Add 155 mg (1.38 mmol) potassium tert-butoxide to the above suspension and stir evenly. After reacting at room temperature for 2 hours, the reaction solution changes from white turbidity to yellow clarification;

[0032] 3) Add 94 mg (0.16 mmol) of the model substance to it, and react for 2 hours at room temperature;

[0033] 4) filter with a sand core funnel filled with silica gel and wash s...

Embodiment 3

[0036] A method for preparing an iron-iron hydrogenase model substance 3 containing an oxapropylene ditellurium bridge, the chemical formula of the model substance 3 is [(μ-TeCH 2 ) 2 O]Fe 2 (CO) 5 (L 2 )[L 2 =1-2,4,6-trimethylphenyl-3-methylimidazole-2-carbene], the preparation process is as follows:

[0037]

[0038] Concrete preparation steps are as follows:

[0039] 1) Under nitrogen protection, add 262mg (0.8mmol) 1-2,4,6-trimethylphenyl-3-methylimidazole iodide and 15mL tetrahydrofuran into a 50mL round-bottomed Schlenk flask equipped with a stirring magnet;

[0040] 2) Add 1 mL (1.6 mmol) of n-butyllithium in n-hexane dropwise to the above suspension, and the reaction solution turns from white turbidity to yellow clarification;

[0041] 3) Add 58 mg (0.1 mmol) of the model substance to it, and react at room temperature for 1.5 h;

[0042] 4) filter with a sand core funnel filled with silica gel and wash several times with dichloromethane to remove inorganic sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com