Flame retardant phenylsilicic acid bisthiophosphatrioxacyclooctyl-4-methyl ester compound and preparation method thereof

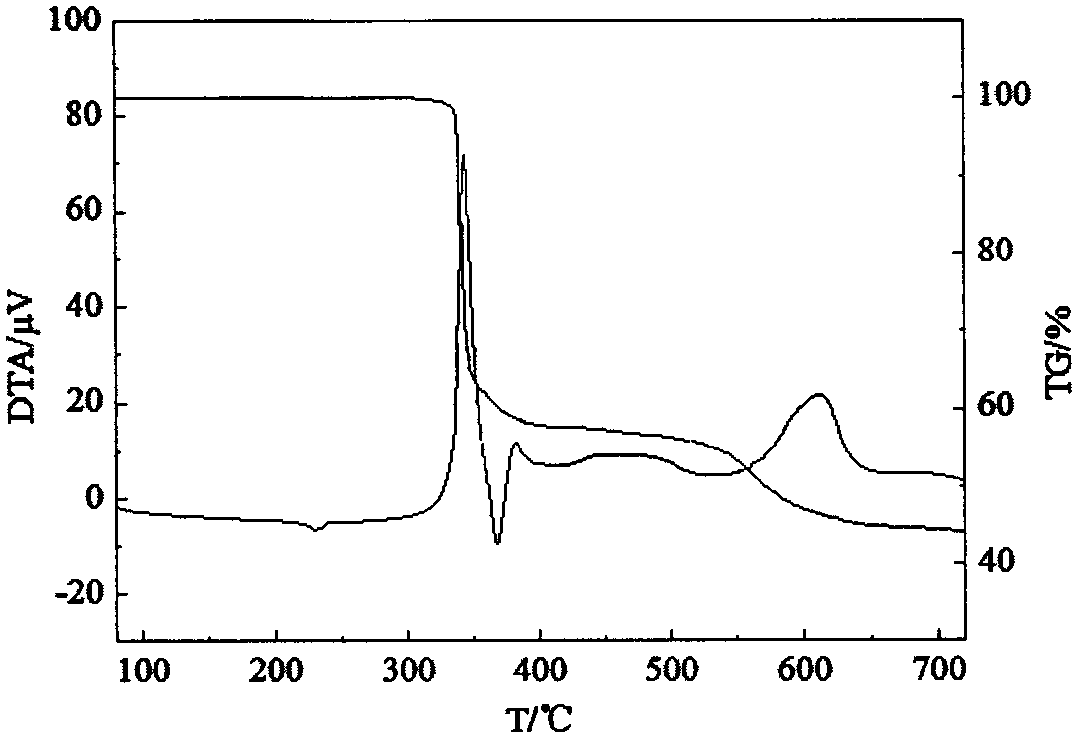

A technology of phenylsilicic acid and trioxabicyclo, which is applied in the field of flame retardant phenylsilicic acid bisthiophosphatrioxacyclooctyl-4-methyl ester compound and its preparation, can solve the problem of life-threatening Property safety, fire and other issues, to achieve the effects of stable physical and chemical properties, good compatibility, and high decomposition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

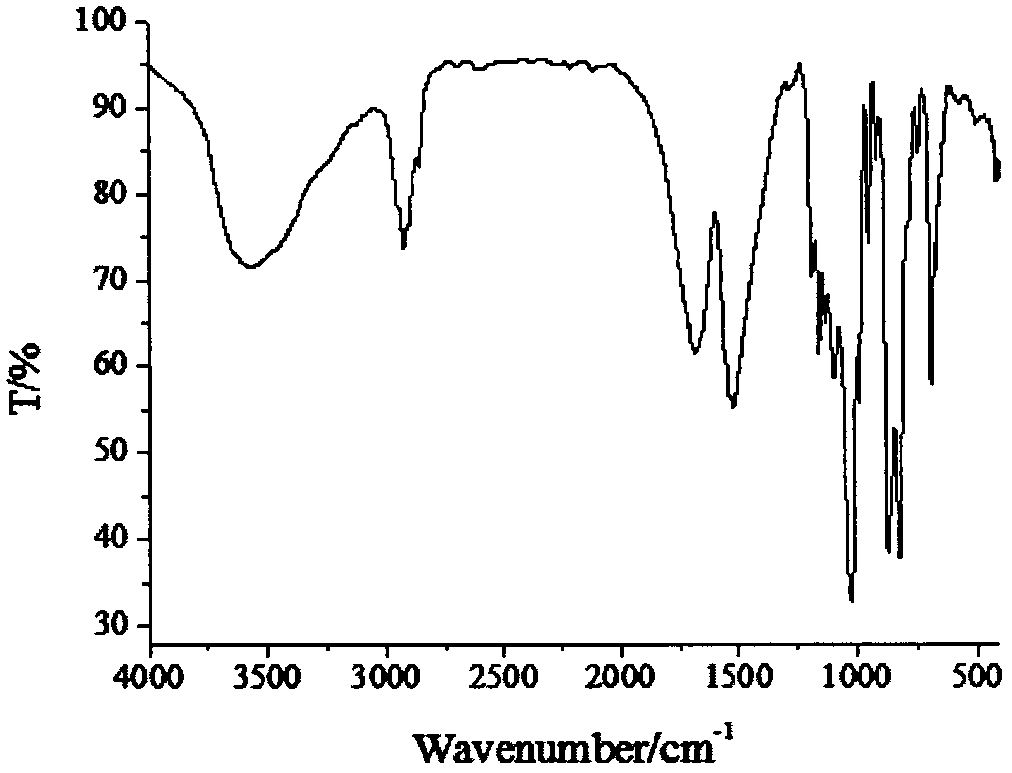

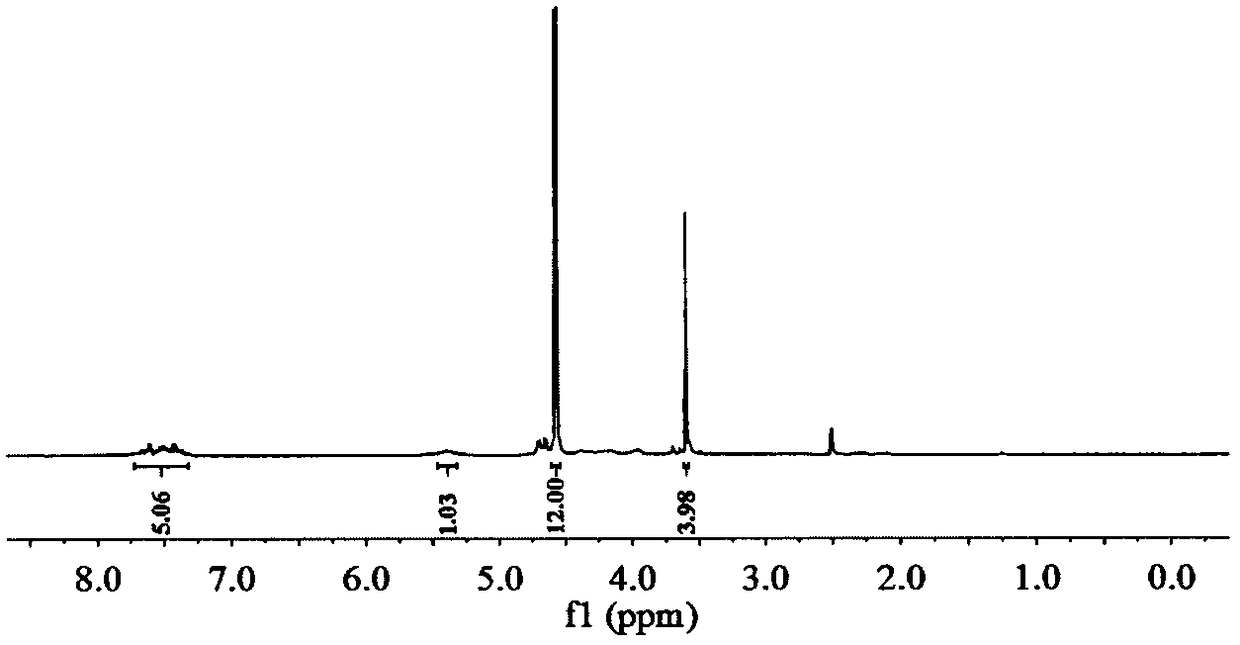

[0026] Example 1 In a 250mL four-necked reaction flask equipped with a stirrer, a thermometer and a hydrogen chloride absorption device, nitrogen was used to drive out the air, and at a temperature of 25°C, 27.46g (0.14mol) of 1-thiophospha-4- Hydroxymethyl-2,6,7-trioxabicyclo[2.2.2]octane and 140ml ethylene glycol dimethyl ether, slowly add 10.58g (0.05mol) phenyltrichlorosilane dropwise, and control the system with the dropping speed The temperature is not higher than 30°C. After the drop is completed, keep it at 50°C for 9 hours; then add distilled water that is equimolar to phenyltrichlorosilane dropwise, raise the temperature to 100°C, and keep it for 2 hours. After the HCl gas is released, add dropwise Adjust the pH of the system to 5-6 with 1.0 g of triethylamine, remove the organic solvent by distillation under reduced pressure, then add 120 mL of ethanol to make slurry for 1 hour, filter with suction, and dry to obtain white solid powder bis-1-thiophospha-2 phenylsilic...

Embodiment 2

[0027] Example 2 In a 250mL four-necked reaction flask equipped with a stirrer, a thermometer and a hydrogen chloride absorption device, nitrogen was used to drive out the air, and at a temperature of 25°C, 22.54g (0.115mol) of 1-thiophospha-4- Hydroxymethyl-2,6,7-trioxabicyclo[2.2.2]octane and 120ml dioxane, slowly add 10.58g (0.05mol) phenyltrichlorosilane dropwise, control system temperature with dropping rate If the temperature is higher than 30°C, keep it at 80°C for 8 hours after dropping; then add distilled water which is equimolar to phenyltrichlorosilane, raise the temperature to 100°C, and keep it for 2 hours. After the HCl gas is released, add 1.5g dropwise Adjust the pH of the system to 5-6 with dimethylaniline, remove the organic solvent by distillation under reduced pressure, then add 80 mL of methanol for beating for 1 hour, filter with suction, and dry to obtain bis-1-thiophospha-2 phenylsilicate as a white solid powder. The yield of 6,7-trioxabicyclo[2.2.2]oct...

Embodiment 3

[0028]Example 3 In a 250mL four-necked reaction flask equipped with a stirrer, a thermometer and a hydrogen chloride absorption device, nitrogen was used to drive out the air, and at a temperature of 25°C, 39.23g (0.20mol) of 1-thiophospha-4- Hydroxymethyl-2,6,7-trioxabicyclo[2.2.2]octane and 180ml ethylene glycol dimethyl ether, slowly add 10.58g (0.05mol) phenyltrichlorosilane dropwise, and control the system by dropping speed The temperature is not higher than 30°C. After the drop is completed, keep it at 40°C for 10 hours; then add distilled water that is equimolar to phenyltrichlorosilane dropwise, raise the temperature to 100°C, and keep it for 2 hours. After the HCl gas is released, add dropwise Adjust the pH of the system to 5-6 with 1.0 g of pyridine, remove the organic solvent by distillation under reduced pressure, then add 140 mL of ethanol to make slurry for 1 hour, filter with suction, and dry to obtain white solid powder of bis-1-thiophospha-2,6 phenylsilicate ,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com