A kind of eugenol-based UV optical resin monomer and its preparation method and application

A technology of optical resin and eugenol, applied in sulfide preparation, organic chemistry and other directions, to achieve the effect of high yield, easy implementation, and oil resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

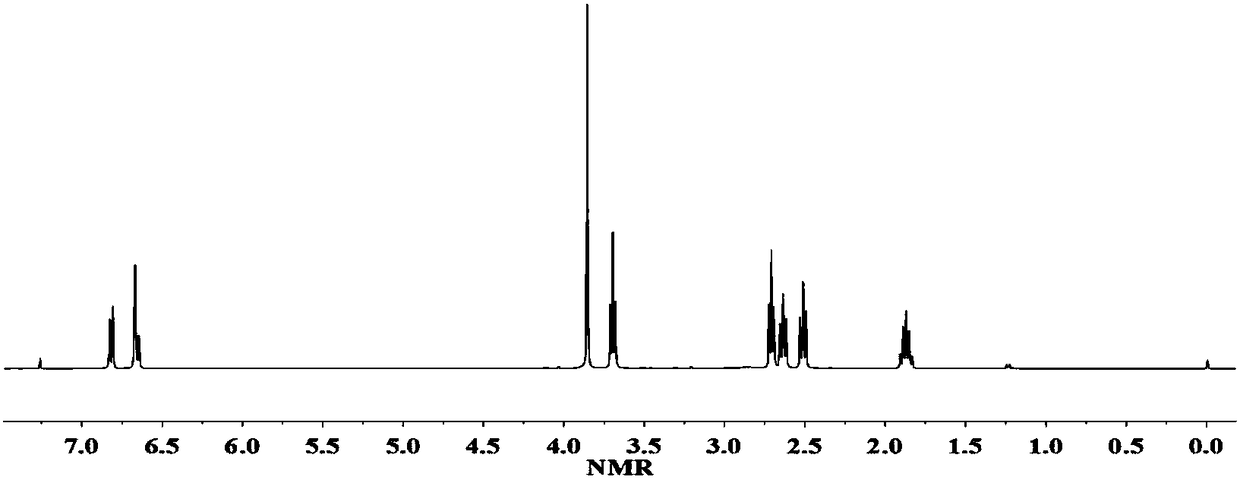

[0050] a) 100g of eugenol, 46g of mercaptoethanol, and 7g of benzoin dimethyl ether were dissolved in a mixed solution of 100mL of dioxane and ethanol, irradiated with a 365nm ultraviolet lamp at 30°C for 2 hours, removed the mixed solvent by rotary evaporation under reduced pressure, and washed with water And obtain eugenol-mercaptoethanol compound after drying, productive rate is 97.5%, hydrogen nuclear magnetic resonance spectrum 1 H-NMR such as figure 1 As shown, each peak on the figure is in one-to-one correspondence with the hydrogen atoms on the eugenol-mercaptoethanol compound structure.

[0051] b) Dissolve 100 g of the eugenol-mercaptoethanol compound prepared above in a mixed solution of 200 ml of dichloromethane and chloroform, add 95 g of methacryloyl chloride, react at 0° C. for 36 hours, distill off the mixed solvent under reduced pressure, and dry to obtain cloves Phenol-mercaptoethanol UV optical resin monomer, yield rate is 90%, structural formula such as fo...

Embodiment 2

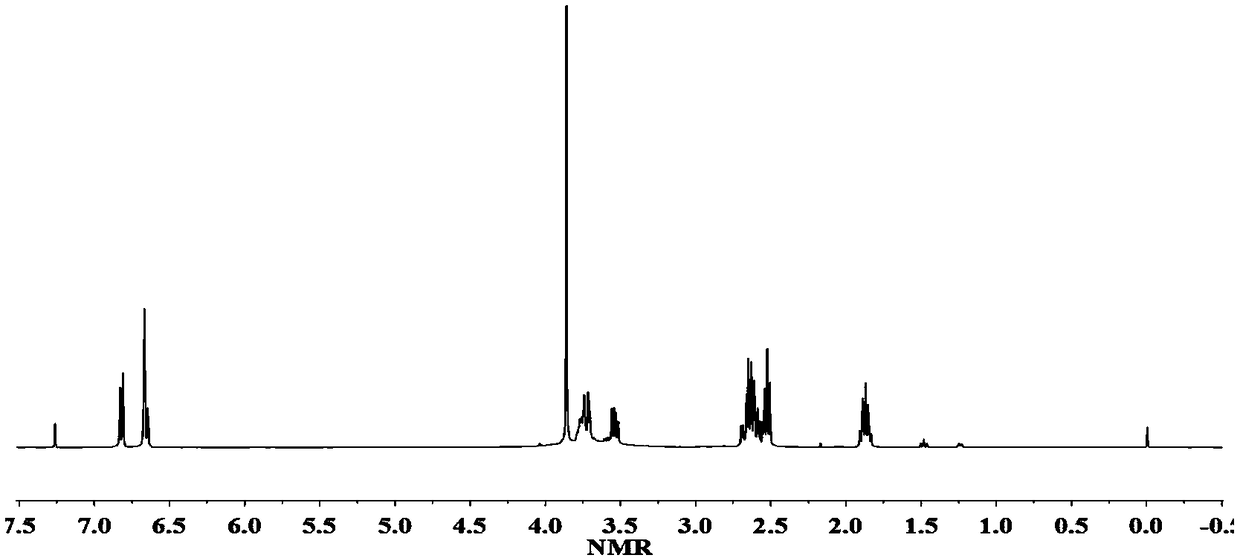

[0055] a) 100g eugenol, 65g mercaptoglycerol, 20g 2-hydroxyl-2-methyl-1-phenylacetone, dissolved in a mixed solution of 100ml dioxane and ethanol, irradiated with a 365nm ultraviolet lamp at 50°C for 0.5 hour, the mixed solvent was removed by rotary evaporation under reduced pressure, washed with water and dried to obtain the eugenol-mercaptoglycerol compound, the productive rate was 92%, and the hydrogen nuclear magnetic resonance spectrum 1 H-NMR such as image 3 As shown, each peak on the figure is in one-to-one correspondence with the hydrogen atoms on the eugenol-mercaptoglycerol structure.

[0056] b) Dissolve 100 g of the eugenol-mercaptoglycerol compound prepared above in a mixed solution of 300 g of dichloromethane and chloroform, add 103 g of methacryloyl chloride, react at 40°C for 12 hours, distill off the mixed solvent under reduced pressure, and dry to obtain cloves The phenol-mercaptoglycerol UV optical resin monomer has a structural formula such as formula VI....

Embodiment 3

[0060] a) 200g eugenol, 50g mercaptoethanol, 28g 1-hydroxycyclohexyl phenyl ketone, dissolved in a mixed solution of 200ml of dioxane and ethanol, irradiated with a 365nm ultraviolet lamp at 40°C for 1 hour, and rotated under reduced pressure The mixed solvent was removed by evaporation, washed with water and dried to obtain the eugenol-mercaptoethanol compound with a yield of 94%.

[0061] b) Dissolve 100 g of the eugenol-mercaptoethanol compound prepared above in a mixed solution of 300 g of dichloromethane and chloroform, add 90 g of methacryloyl chloride, react at 30° C. for 24 hours, distill off the mixed solvent under reduced pressure, and dry to obtain cloves The phenol-mercaptoethanol UV optical resin monomer has a yield of 99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com