Plant-growth-promoting bio-organic fertilizer and preparation method

A bio-organic fertilizer and plant growth-promoting bacteria technology is applied in the preparation of organic fertilizers, the treatment of bio-organic parts, and organic fertilizers. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

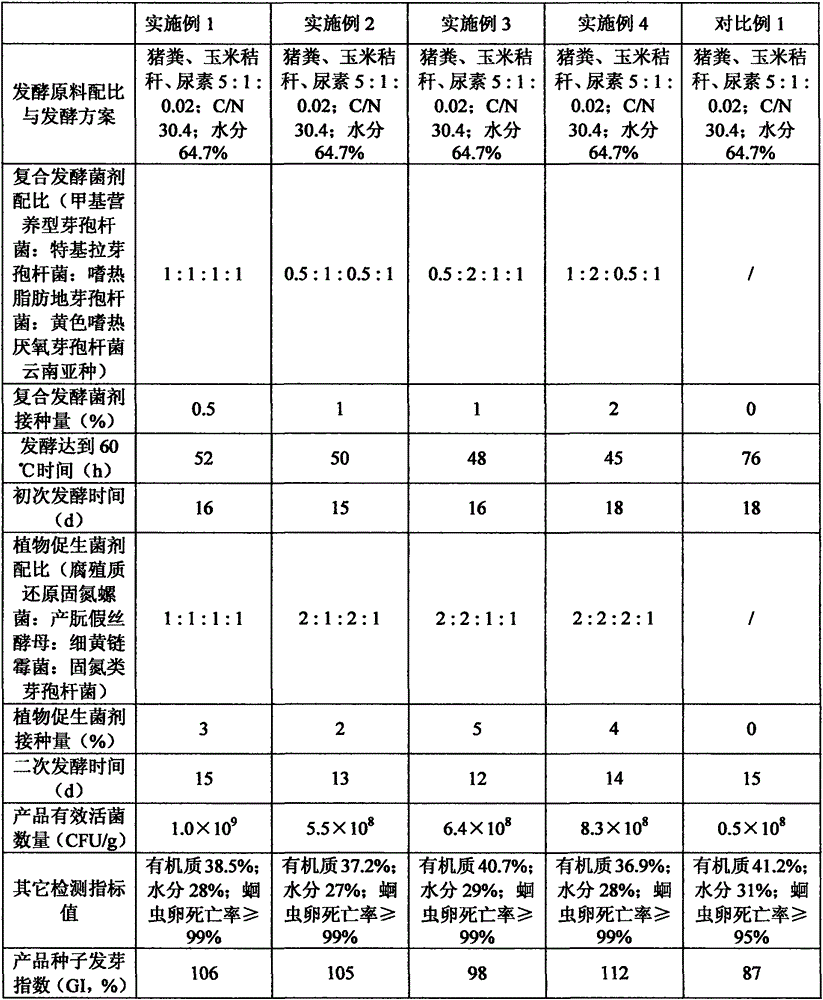

Embodiment 1~4

[0018] The bio-organic fertilizer is prepared by mixed fermentation of pig manure, corn stalks, urea and functional microbial agents as follows:

[0019] (1) Pig manure, corn stalks and urea are used as raw materials to ferment bio-organic fertilizers. The total mass of fermented materials is 300kg. The ingredients are prepared according to the wet weight ratio of pig manure: corn stalks: urea 5: 1: 0.02. The properties of the three materials are shown in Table 1. The C / N ratio of the mixed material is 30.4, and the moisture content is 64.7%.

[0020] Table 1 Properties of pig manure, corn stalks and urea

[0021] project pig manure Corn stalks urea Total organic carbon (g kg -1 )

374.5 441.8 0 Total nitrogen (g kg -1 )

11.4 5.7 46.7 C / N 32.9 77.5 0 Moisture content (%) 73.8 20.4 11.5

[0022] (2) Inoculate 2 loops of each of the methylotrophic Bacillus, Bacillus tequila, Geobacillus stearothermophilus and Bacillus x...

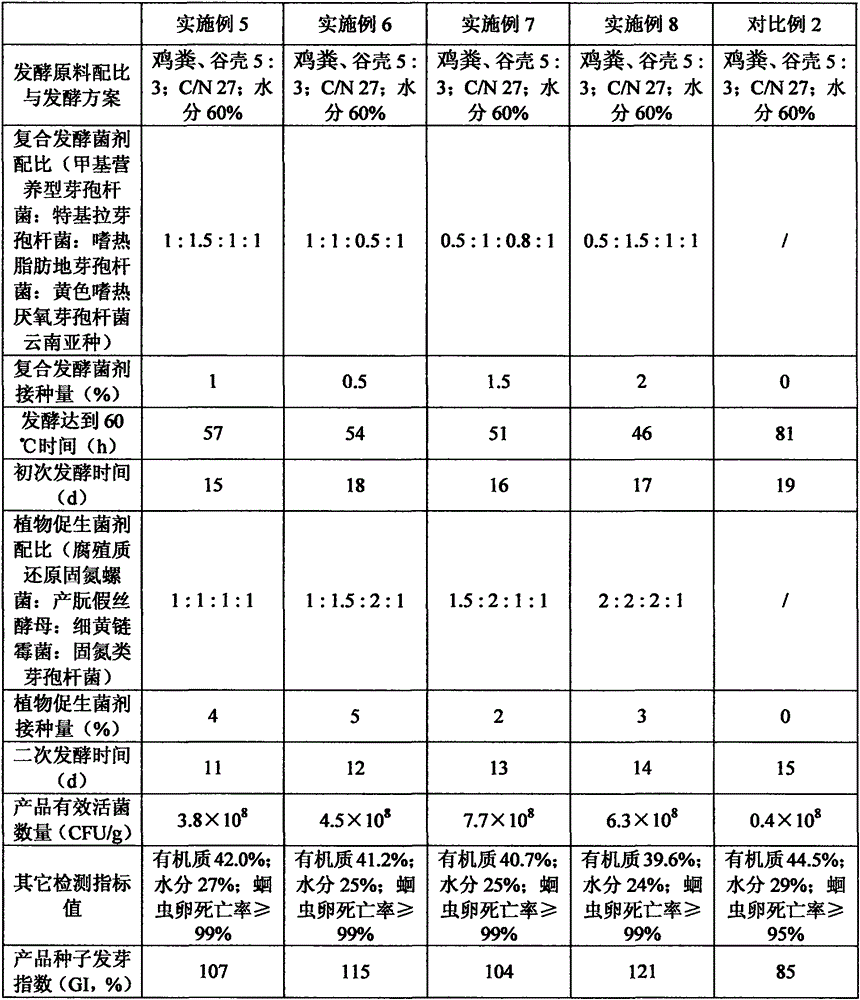

Embodiment 5~8

[0035] Bio-organic fertilizer is prepared by mixed fermentation of chicken manure, rice husk and functional microbial agent:

[0036] (1) The bio-organic fertilizer was prepared by fermenting chicken manure and crushed rice husk as raw materials. The total mass of the fermented material was 200 kg. The C / N ratio of the mixed material is 27, and the moisture content is 44.8%. Water is added before fermentation to adjust the moisture content of the heap to 60%.

[0037] Table 3 Material properties of chicken manure and rice husk

[0038] project chicken manure rice husk Total organic carbon (g kg -1 )

305 457.2 Total nitrogen (g kg -1 )

30.6 4.1 C / N 10 111.5 Moisture content (%) 64.8 11.8

[0039] (2) Inoculate 2 loops of each of the methylotrophic Bacillus, Bacillus tequila, Geobacillus stearothermophilus and Bacillus xanthoanaerobicus subsp. Activation at 30°C, 45°C, 55°C and 60°C for 24 hours. Then the culture solution ...

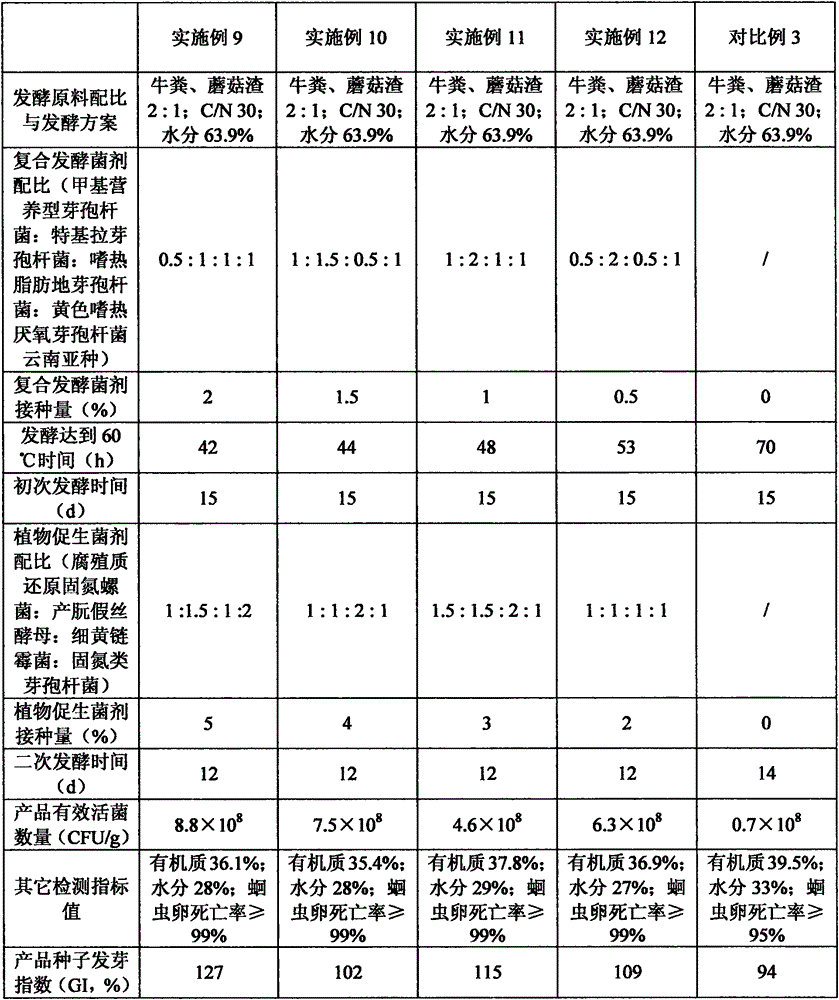

Embodiment 9~12

[0052] Bio-organic fertilizer is prepared by mixed fermentation of cow dung, mushroom dregs and functional microbial agents:

[0053] (1) Cow dung and mushroom dregs were fermented to prepare bio-organic fertilizer. The total mass of the fermented material was 500 kg, and the ingredients were mixed according to the wet weight ratio of cow dung and mushroom dregs of 2:1. The properties of the two materials are shown in Table 5. The C / N ratio of the mixed material is 30, and the moisture content is 63.9%.

[0054] The material properties of table 5 cow dung and mushroom dregs

[0055] project cow dung Mushroom residue Total organic carbon (g kg -1 )

325.4 385.1 Total nitrogen (g kg -1 )

1.45 0.98 C / N 22.4 39.3 Moisture content (%) 75.8 41.5

[0056] (2) Inoculate 2 loops of each of the methylotrophic Bacillus, Bacillus tequila, Geobacillus stearothermophilus and Bacillus xanthoanaerobicus subsp. Activation at 30°C, 45°C, 55°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com