Cadmium-reducing selenium-enriched organic fertilizer for crops as well as preparation method and application thereof

An organic fertilizer and selenium-enriched technology, applied in the field of agricultural production, can solve the problems of long period of phytoremediation, difficult to apply in a large area, poor cadmium stability, etc., and achieve the effects of inhibiting absorption, increasing the content of organic matter, and reducing the effect of cadmium.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

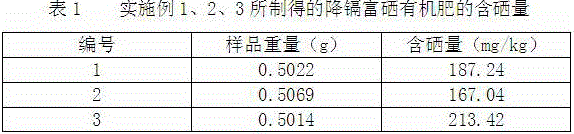

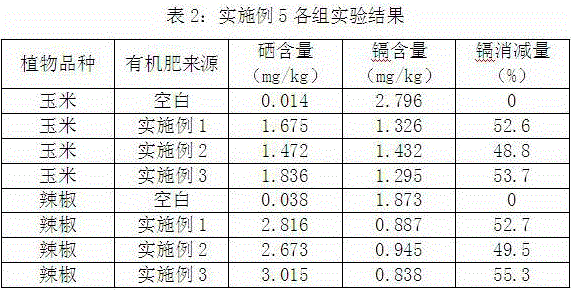

Embodiment 1

[0041] In the fermentation tank, the plant residues composed of camellia seed meal, oil waste clay, camellia seed hulls and tea residues were mixed uniformly in a weight ratio of 50: 8: 20 to prepare a mixture, and the mixture was sprayed with 5 grams of sodium selenite. / Kg of aqueous solution. After stirring, the water content of the mixture is measured to be 55%; the mixture is piled into 1.5~2 meters high and 2~3 meters wide for composting and fermentation, when the temperature rises to 60~65℃ Turning and throwing equipment is used for the first turning treatment; the temperature of the mixture to be turned has dropped to room temperature and then stacked again. When the temperature rises to 60~65℃, the stack will be turned over again, and the sodium selenite aqueous solution should be sprayed to ensure the content of the mixture. The water content is 50-60%. After repeating this process for 6 times, the temperature of the pile body will drop to room temperature and no longe...

Embodiment 2

[0043] In the fermentation tank, the plant residues composed of camellia seed meal, oil waste clay, camellia leaves and camellia flowers are mixed uniformly in a weight ratio of 48:7:18 to prepare a mixture, and the mixture is sprayed with sodium selenite content of 8 g / The water content of the mixture is 58% after stirring evenly. The mixture is piled into 1.5~2 meters high and 2~3 meters wide for composting and fermentation. When the temperature rises to 60~65℃ Use turning and throwing equipment for the first turning treatment; the temperature of the mixture to be turned down to room temperature is re-stacked, and when the temperature rises to 60-65℃, turning the stack again, and spraying sodium selenite aqueous solution to ensure the water content of the mixture After repeating this process at 50-60% for 7 times, the stack temperature drops to room temperature and no longer rises. The fermentation process is over; the mixture after the fermentation process is stacked into st...

Embodiment 3

[0045] In the fermentation tank, the plant residues composed of camellia seed meal, oil waste clay, tea trees and tea residues are mixed uniformly in a weight ratio of 55:8:25 to prepare a mixture, and the mixture is sprayed with sodium selenite content of 6 g / The water content of the mixture is measured to be 60% after mixing evenly with kilograms of aqueous solution; the mixture is stacked into 1.5-2m high and 2-3m wide strips for composting and fermentation, when the temperature rises to 60-65℃ Use turning and throwing equipment for the first turning treatment; the temperature of the mixture to be turned down to room temperature is re-stacked, and when the temperature rises to 60-65℃, turning the stack again, and spraying sodium selenite aqueous solution to ensure the water content of the mixture At 50-60%, after repeating this process for 10 times, the stack temperature drops to room temperature and no longer rises. The fermentation process ends; the mixture after the ferme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com