Treatment system for organic matters in petrochemical sewage reverse osmosis concentrated water and treatment method thereof

A technology of reverse osmosis concentrated water and petrochemical sewage, applied in the field of environmental engineering, can solve the problems of catalyst packing bed scaling and hardening, poor biodegradability, large ozone consumption, etc., achieve remarkable removal effect, mild reaction conditions, and easy operation and maintenance simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below in conjunction with specific embodiments. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form. It should be noted that those skilled in the art can make several modifications and improvements without departing from the concept of the present invention. These all belong to the protection scope of the present invention.

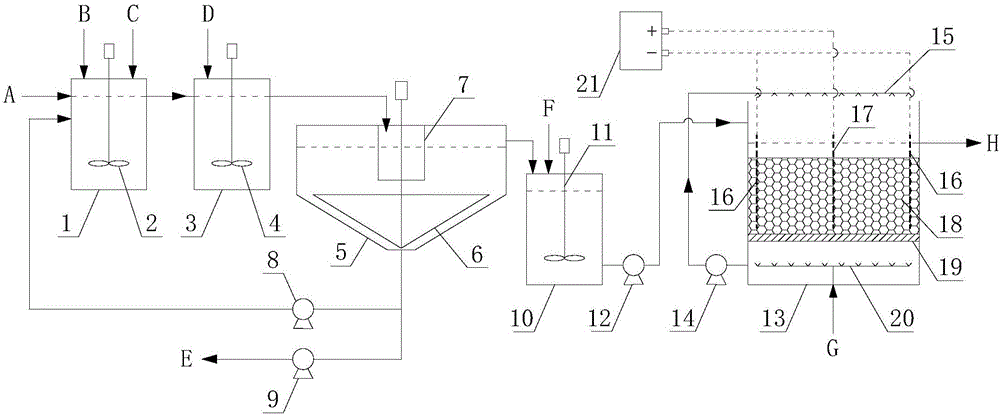

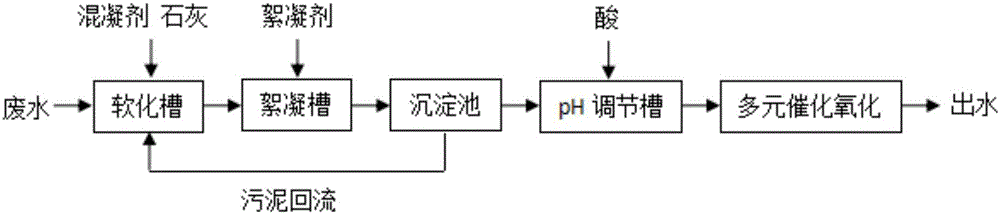

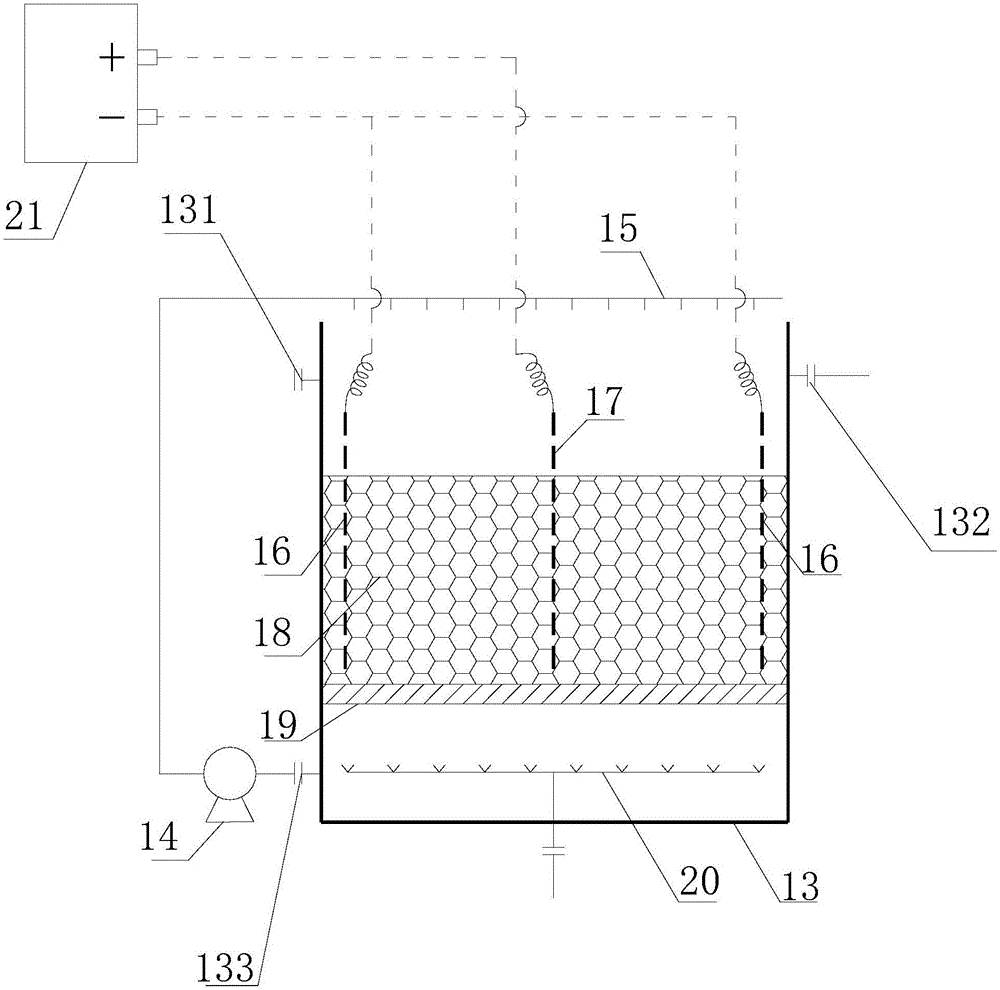

[0050] The invention provides a treatment system for organic matter in reverse osmosis concentrated water of petrochemical sewage, such as figure 1 , 3 As shown in ~5, it includes: softening tank 1, flocculation tank 3, sedimentation tank 5, pH adjustment tank 10, multi-component catalytic oxidation device connected in sequence, sedimentation tank 5 and softening tank 1 are connected through sludge return pump 8, softening A softening tank mixer 2 and a flocculation tank mixer 4 are installed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com