Preparation method of low-cost and large-tow 48K carbon fiber preimpregnated cloth and composite material thereof

A carbon fiber prepreg, composite material technology, applied in the field of high-performance fiber composite material manufacturing, can solve the problems of product quality stability, single structure, high cost, etc., to expand the application form and scope of application, low cost, reduce manufacturing cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

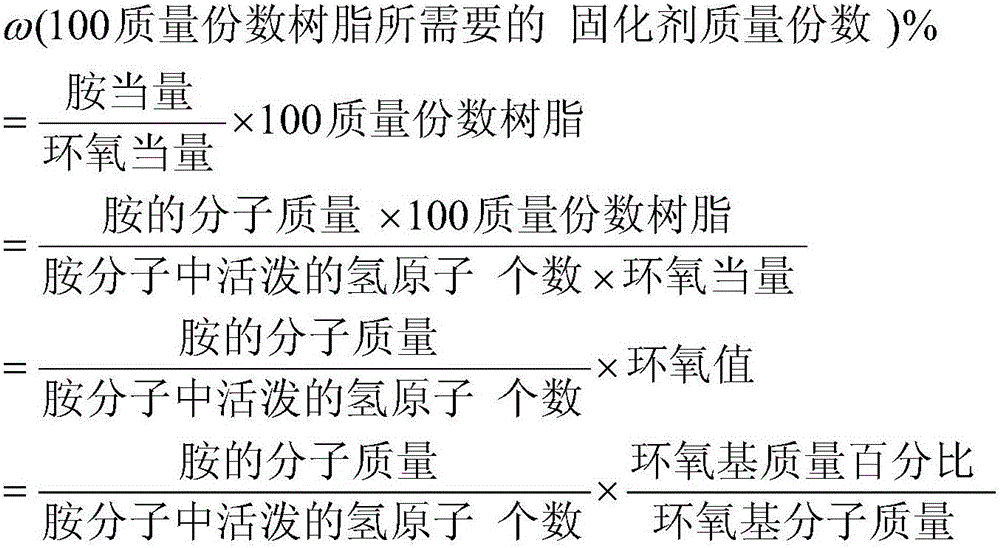

[0044] An epoxy resin-based carbon fiber prepreg and its composite material prepared from domestic 48K large-tow carbon fiber as raw material, the prepreg and its composite material are composed of epoxy resin system composition and 48K large-tow carbon fiber reinforced fabric , the epoxy resin system is jointly configured by an epoxy resin group and a curing agent group, and the epoxy resin group includes epoxy resin, diluent, coupling agent, defoamer and antioxidant. Take 80 parts by mass of E51 type epoxy resin, 14 parts of 1,4 butanediol diglycidyl ether, 2 parts of 3-glycidyl ether propoxy triethoxysilane, 1 part of tributyl phosphite Under the temperature range of 20℃~30℃, stir for 30min~40min until the mixture is uniform, add 0.6 parts of BYK-A530 defoamer to keep the temperature constant, stir for 15min, and finally stand for 12h for use. Get 12 parts of isodiethylenetriamine according to the stoichiometric weight of the epoxy resin as the curing agent component. Mix ...

Embodiment 2

[0048] An epoxy resin-based carbon fiber prepreg and its composite material prepared from domestic 48K large-tow carbon fiber as raw material, the prepreg and its composite material are composed of epoxy resin system composition and 48K large-tow carbon fiber reinforced fabric , the epoxy resin system is jointly configured by an epoxy resin group and a curing agent group, and the epoxy resin group includes epoxy resin, diluent, coupling agent, defoamer and antioxidant. Get 80 parts of bisphenol F type epoxy resins (DER354), 14 parts of butyl glycidyl ethers, 2 parts of 3-glycidyl ether propoxy triethoxysilanes, 1 part of tributyl phosphite by mass parts Under the temperature range of 20℃~30℃, stir for 30min~40min until the mixture is uniform, add 0.6 parts of BYK-A530 defoamer to keep the temperature constant, stir for 15min, and finally stand for 12h for use. Get according to the stoichiometric weight with epoxy resin, get 27 parts of diamine diphenylmethane as curing agent c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com