System and process used for preparing SBS modified asphalt

A technology for modifying asphalt and bitumen, applied in building components, building insulation materials, buildings, etc., can solve problems such as low production efficiency of modified asphalt, and achieve the effects of reducing energy consumption, improving production efficiency, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

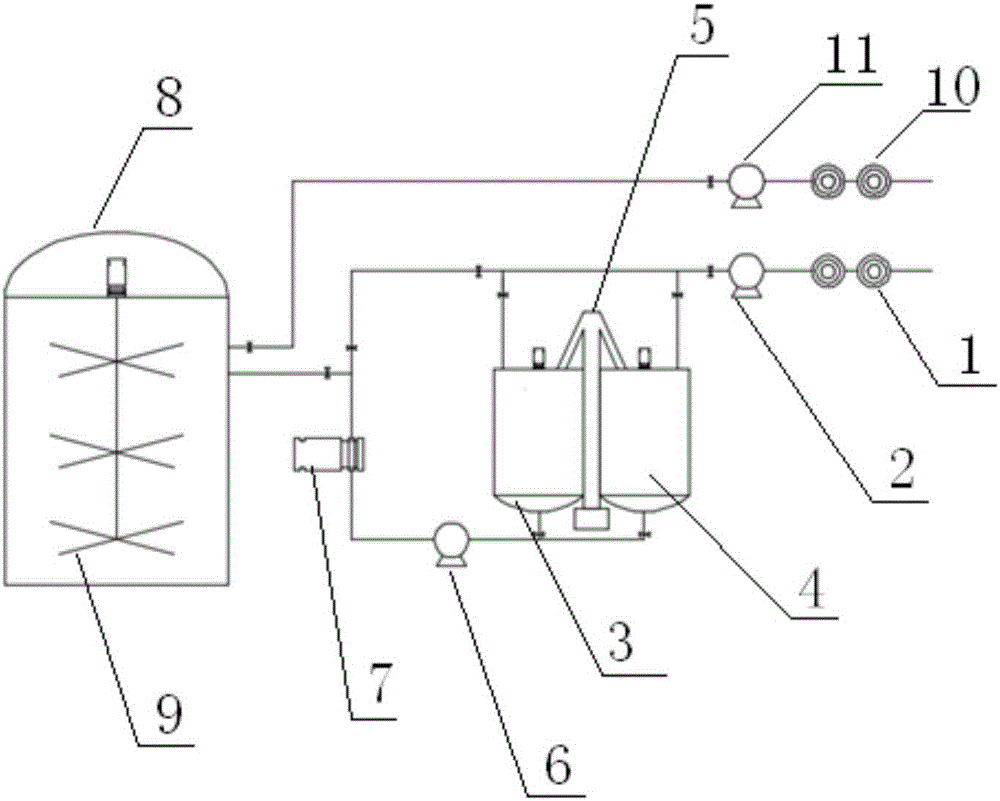

[0039] This embodiment provides a system for preparing SBS modified asphalt, such as figure 1 As shown, the system includes pipelines connected sequentially in the direction of asphalt flow

[0040] The first heat exchanger group 1 is located at the entrance of the grinding system,

[0041] The first batching tank 3 is communicated with the first heat exchanger group 1 through the first base asphalt feed pump 2, and an SBS lifting device 5 is arranged near the first batching tank 3 for putting SBS materials into the station. Describe the first batching tank 3,

[0042] The colloid mill 7 communicates with the bottom outlet of the first batching tank 3 through the modified asphalt discharge pump 6,

[0043] The finished product tank 8 is located at the downstream of the colloid mill 7 and communicates with the colloid mill 7 through a pipeline;

[0044] It also includes a second heat exchanger group 10 arranged at the entrance of the preparation system and parallel to the fi...

Embodiment 2

[0056] This embodiment provides a process for SBS modified asphalt. Taking the production of 1000 tons of modified asphalt and the addition of SBS as 3.5% as an example, 965 tons of base asphalt and 35 tons of SBS are required. The specific process steps are as follows:

[0057] 465 tons of base asphalt enters the first batching tank through the first heat exchanger group through the first asphalt feed pump, and at the same time, SBS passes through the SBS lifting device to add 35 tons of SBS to the first batching tank. After the batching is completed, the premixed liquid in the first batching tank is pumped into the finished product tank through the asphalt discharge pump through the shearing machine. At the same time, the first asphalt feed pump continues to pump 500 tons of base asphalt into the second batching tank for continuous batching. Cut into the finished product cans.

Embodiment 3

[0059] This embodiment provides a process for SBS modified asphalt. Taking the production of 800 tons of modified asphalt with an SBS addition of 4% as an example, 768 tons of base asphalt and 32 tons of SBS are required. The specific process steps are as follows:

[0060] 368 tons of base asphalt enters the first batching tank through the first heat exchanger group through the first asphalt feed pump, and at the same time, SBS passes through the SBS lifting device to add 32 tons of SBS to the first batching tank. After the batching is completed, the premixed liquid in the first batching tank is pumped into the finished product tank through the asphalt discharge pump and through the shearing machine. At the same time, the first asphalt feed pump continues to pump 300 tons of base asphalt into the second batching tank for continuous batching. Cut into the finished product cans.

[0061] At the same time, 100 tons of base asphalt is directly pumped into the finished product ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com