Particulate detergent composition and process for producing the same

A detergent and composition technology, which is applied in the field of granular detergent compositions and can solve the problems of reduced production efficiency and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

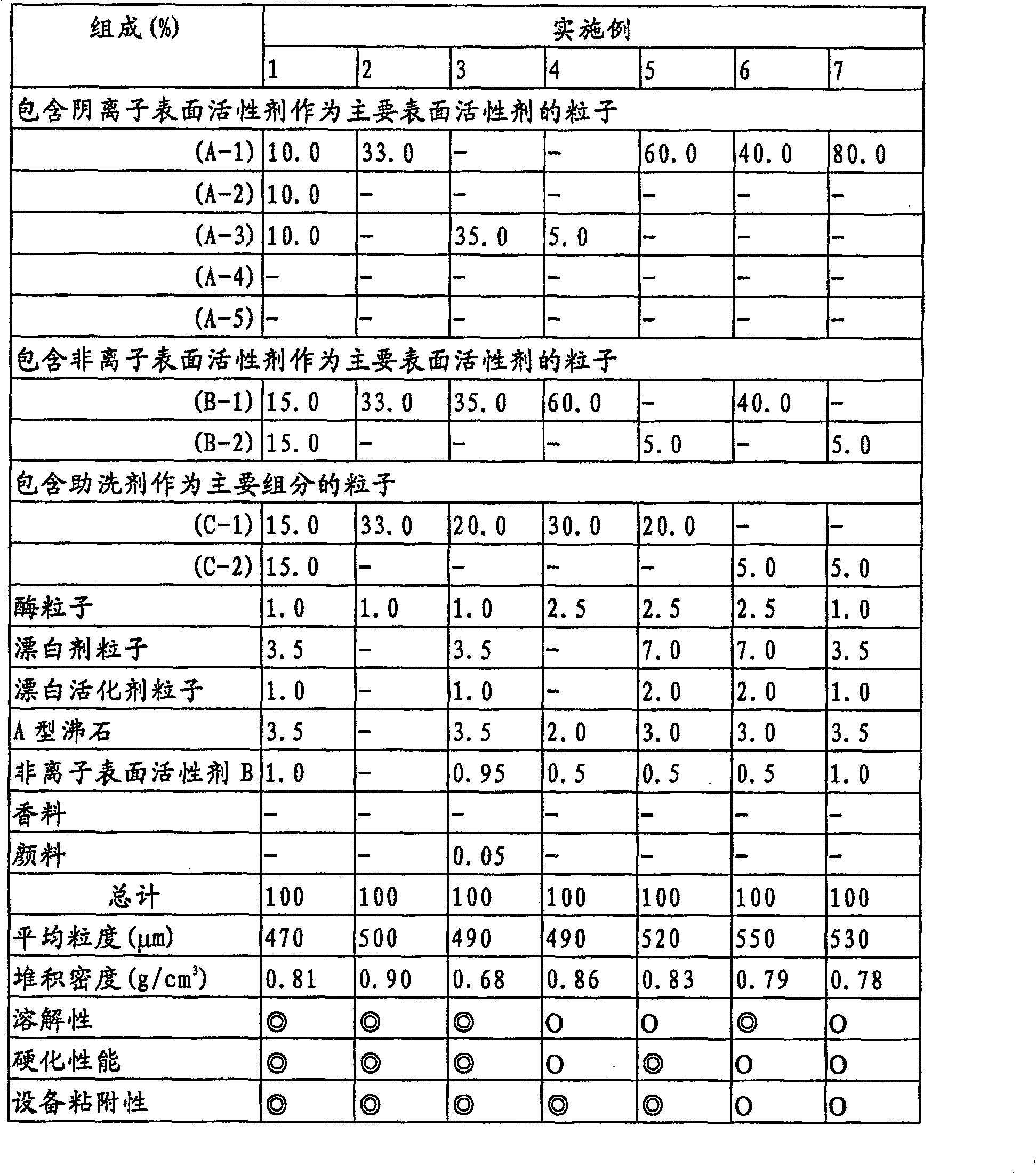

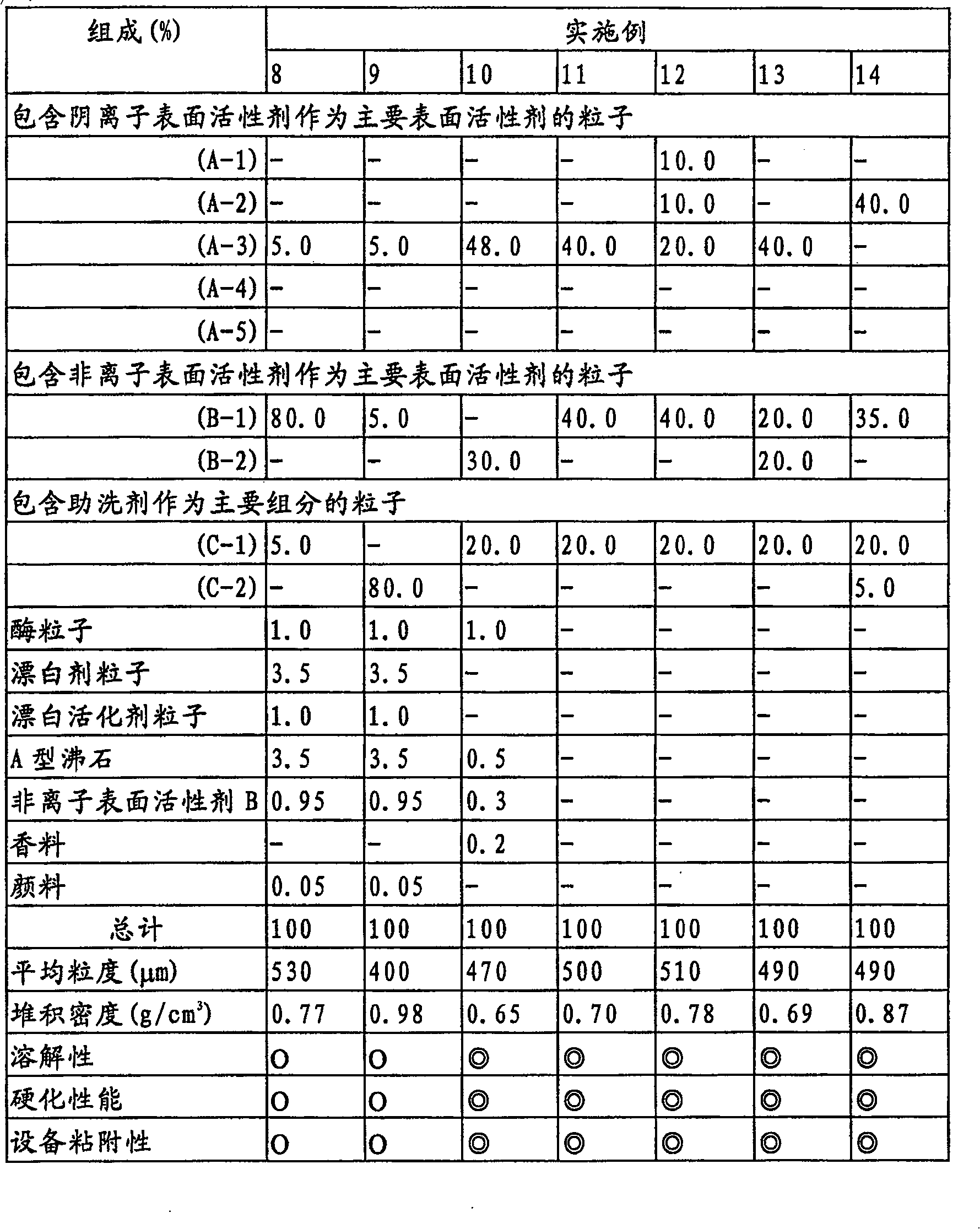

Examples

preparation Embodiment 1

[0200] (A-1) Preparation of Detergent Particles Containing Anionic Surfactant as Main Surfactant

[0201] (A-1-1) Granulation of detergent particles

[0202] Composition (A-1) in Table 1 was made of non-ionic surfactant-free components, 4.0% equivalent of type A zeolite for addition during kneading, 5.2% equivalent of type A zeolite for grinding aid Zeolite, 1.5% equivalent of zeolite type A for surface covering, and pigment and fragrance were dissolved or dispersed in water to prepare a slurry with 40% water. The resulting slurry was then spray-dried using a counter-current spray-drying tower at a hot air temperature of 300°C to obtain spray-dried granules with 4% water. This spray-dried granule, 4.0% equivalent of A-type zeolite, nonionic surfactant, and water were loaded into a continuous kneader (KRC-S4 type, product of Kurimoto Ltd.) at a temperature of 60° C. by 120 kg The kneading capacity of / h kneads the resulting mixture to obtain an indeterminate solid detergent. ...

preparation Embodiment 2

[0209] (A-2) Preparation of detergent particles comprising anionic surfactant as main surfactant

[0210] (A-2-1) Granulation of detergent particles

[0211] The non-ionic surfactant-free components of the composition (A-2) in Table 1, 3.0% equivalent of A-type zeolite for grinding aid, 0.5% equivalent of A-type zeolite for surface coating, pigment and The fragrance is dissolved or dispersed in water to prepare a 38% water slurry. Then, the resulting slurry was spray-dried by hot air at 300° C. using a counter-current spray drying tower to obtain spray-dried granules with 3% water. This spray-dried granule, nonionic surfactant, and water were loaded into a continuous kneader (KRC-S4 type, product of Kurimoto Ltd.), and kneaded at a temperature of 60° C. with a kneading capacity of 120 kg / h The resulting mixture gave an amorphous solid detergent. This indefinite form solid detergent is equipped with the extruder (EXDFJS-100 type, the product of FujiPaudal Co., Ltd.) of the d...

preparation Embodiment 3

[0218] (A-3) Preparation of detergent particles comprising anionic surfactant as main surfactant

[0219] (A-3-1) Dry neutralization with a fluidized bed

[0220] The powder raw material (not including the coating agent) comprising the potassium carbonate and sodium carbonate ground products in the amounts shown in Table 1 (A-3) was charged into a fluidized bed (Glatt-POWREX, model FD-WRT-20, Powrex Corp. In the product of ), this amount of powder raw material results in a powder layer thickness of 200 mm during standing. Then the air at 20°C flows into the fluidized bed to fluidize the powder, and then the α-SF-H is shot towards the powder layer and sprayed on the powder from above. The granulation is performed while ensuring the fluidized state by adjusting the air velocity in the fluidized bed within the range of 0.2 to 2.0 m / s.

[0221]The α-SF-H was sprayed at 60°C, and a two-phase hollow cone nozzle with a spray angle of 70° was used as the nozzle for spraying. The sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com