Slice controlling device for slicer

A technology of a control device and a slicer, which is applied in the application and processing of tobacco, tobacco, etc., can solve the problems such as the influence of the uniformity of the tobacco sheet, the influence of the flow control of the tobacco sheet, and the disparity, etc., and achieves the improvement of slicing accuracy, simple debugging, and improved stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below with reference to the drawings and embodiments.

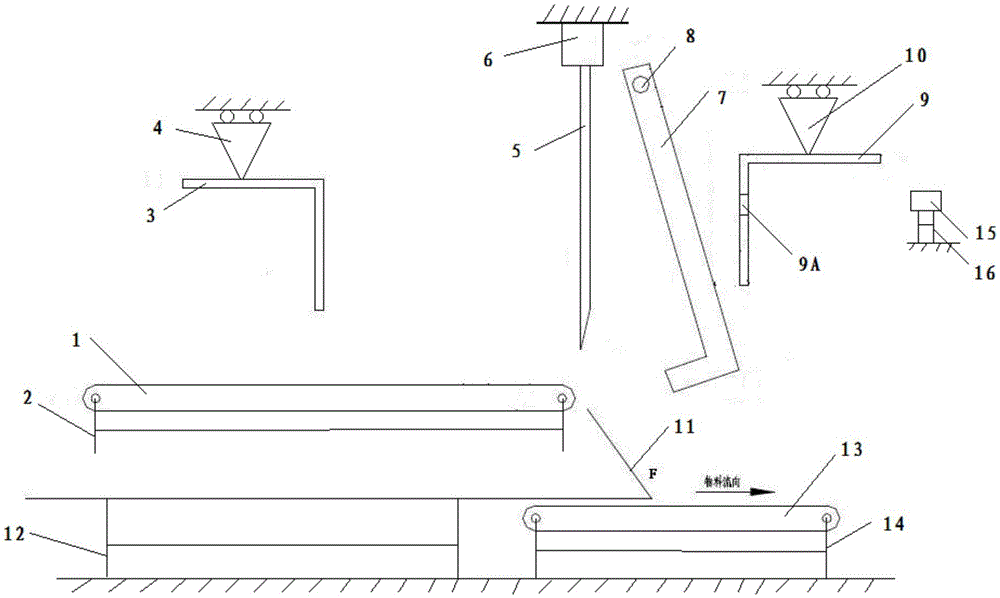

[0017] Such as figure 1 As shown, a slicing control device for a tablet machine provided by the present invention includes a feeding device 1, a feeding support 2, a pushing device 3, a pushing synchronous toothed belt transmission system 4, and a cutter 5. , Cutting cylinder 6, turning device 7, rotating shaft 8, blocking device 9, blocking step toothed belt transmission system 10, guiding device 11, discharging support 12, transfer material device 13, transfer material support 14 and Laser ranging sensor 15. The rotating shaft of the feeding device 1 is supported on the feeding support 2, and the feeding device 1 can rotate relative to the feeding support 2; the upper side plate of the pushing device 3 is fixed on the pushing synchronous toothed belt transmission system 4 by screws, The pushing device 3 is located above the feeding device 1, and the pushing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com