Device for splinter processing and method thereof

A technology of splitting and equipment, applied in nonlinear optics, instruments, optics, etc., can solve the problems of low efficiency and inability to handle the splitting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] In order to make the structural features of the present invention and the achieved effects have a further understanding and recognition, preferred embodiments and detailed descriptions are specially used, which are described as follows:

[0070] Currently, there are many splitting methods for liquid crystal display panels, such as clamping, knocking, breaking and high-velocity hot gas. However, equipment using the above-mentioned splitting process cannot achieve streamlined production. Generally, the equipment for the splitting process requires a short residence time for splitting processing, so it is difficult to meet the existing manufacturing needs of a large number of liquid crystal display panels. and its methods.

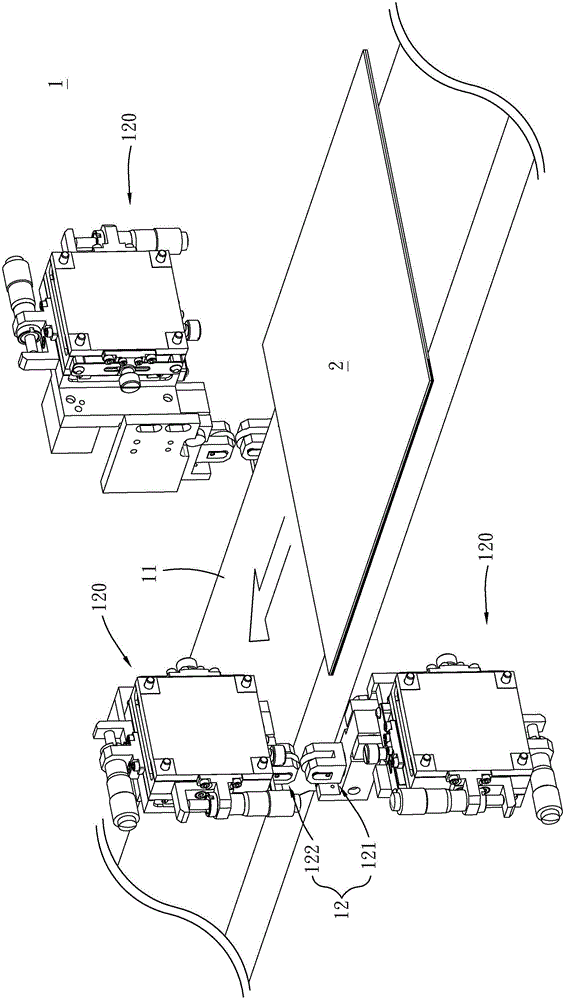

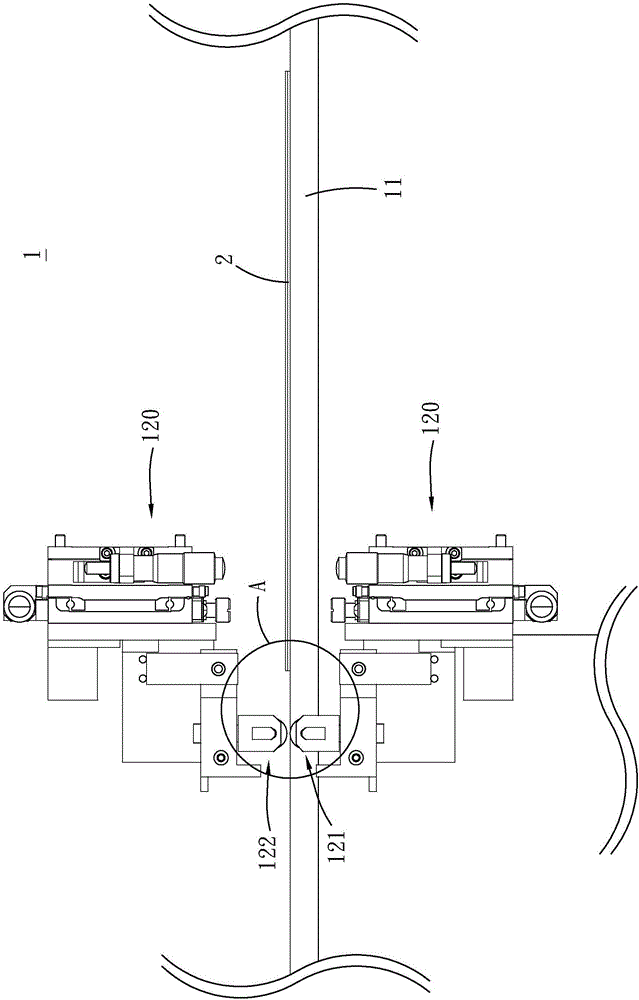

[0071] see figure 1 and figure 2 , which is a schematic diagram and a side view of the splitting process equipment in the first embodiment of the present invention; A split roller set 12, the at least one split roller set 12 is fixed on one side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com