A novel mining vehicle elastic coupling

An elastic coupling and mine-used technology, which is applied in the direction of elastic couplings, couplings, mechanical equipment, etc., can solve problems such as waste of materials, and achieve the effects of improving service life, smooth transmission, and convenient daily maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

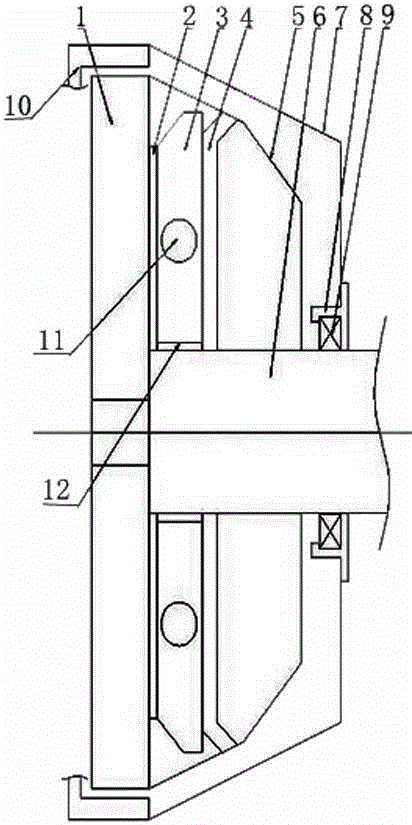

[0022] The present invention as figure 1 shown.

[0023] A new type of elastic coupling for mining vehicles, including an engine flywheel 1, the engine flywheel 1 is installed in the flywheel housing 10, and the flywheel housing 10 is also connected with a casing 7, and the engine flywheel 1 is output through the power output shaft 6, wherein the power output shaft 6. The output of the casing 7 is fixed in the bearing seat 8 through the bearing 9, and then output. The connecting surface of the engine flywheel 1 facing the direction of the power output shaft 6 is provided with a friction plate 2, a driven wheel assembly 3, a membrane The leaf spring 4, the pressure plate 5, the friction plate 2, the driven wheel assembly 3, the diaphragm spring 4, and the pressure plate 5 are connected to the engine flywheel 1 through the power output shaft 6 as a coupling.

[0024] The driven wheel assembly 3 is provided with a damping spring 11 .

[0025] Both sides of the friction plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com