Method for preparing tackifier copolymerization associate

The technology of an associate and a tackifier is applied in the field of preparation of polymers for drilling fluids, which can solve the problem of no obvious improvement in salt resistance and calcium resistance, and achieve the effects of high shear force, temperature resistance and salt resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

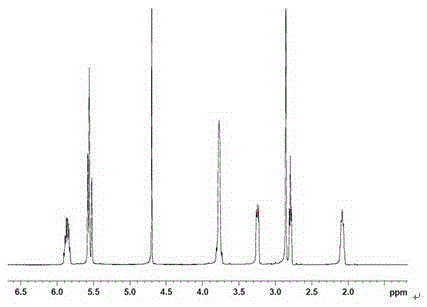

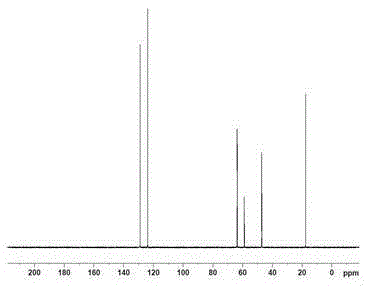

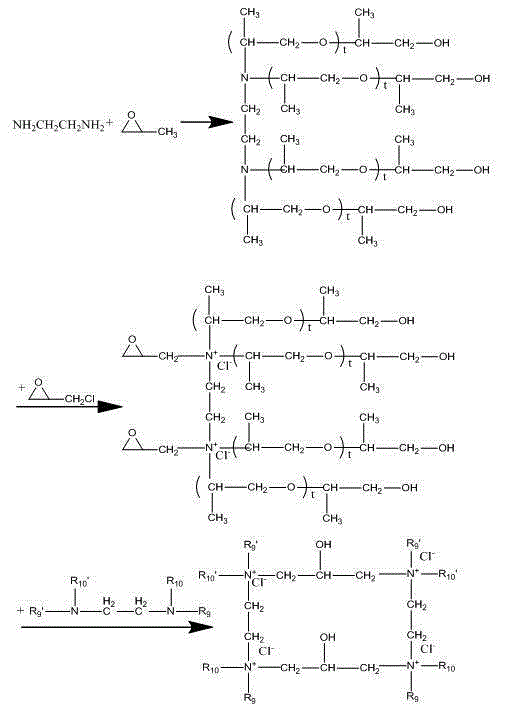

Embodiment 1

[0062] Add 2.5g of OP15 and 22.5g of Span 80 into 150g of white oil, pass N under stirring condition 2 Deoxygenate for half an hour, prepare the oil phase for later use; add 37.5g NaCl to 140g water and fully dissolve it to prepare an aqueous NaCl solution, then add 18g MAPS and 63gDMAM to the NaCl aqueous solution, stir to fully dissolve it; transfer the oil phase to the reactor Add the water phase dropwise to the oil phase while stirring, and stir for half an hour to obtain an emulsification system; add 0.24g potassium persulfate to the emulsification system, and pass N 2 Deoxygenation for half an hour, while raising the temperature to 60 ° C, and reacting for 1 hour to obtain an intermediate product; then dissolving 2 g of cationic polyamine 1 in 10 g of deionized water to prepare a cationic polyamine solution, and then adding the cationic polyamine solution to the intermediate product, Mix evenly, and at the same time raise the temperature to 70°C, and continue the reactio...

Embodiment 2

[0064] Add 1.5g of OP15 and 13.5g of Span 80 into 75g of white oil, pass N under stirring condition 2 Deoxygenation for half an hour, the oil phase was prepared for use; 20gCaCl 2 Add to 140g water and fully dissolve to make CaCl 2 aqueous solution, then 47gMAPS and 46gDMAM were added to the CaCl 2 In the aqueous solution, stir to fully dissolve it; transfer the oil phase to the reactor, add the water phase to the oil phase dropwise while stirring, and stir for half an hour to obtain an emulsification system; add 0.32g of sodium persulfate to the emulsification system, wait After fully dissolved, pass N 2 Deoxygenation for half an hour, while raising the temperature to 55 ° C for 1.5 hours to obtain an intermediate product; then dissolving 4 g of cationic polyamine 2 in 10 g of deionized water to prepare a cationic polyamine solution, and then adding the cationic polyamine solution to the intermediate product, Mix evenly, and at the same time raise the temperature to 65°C, ...

Embodiment 3

[0066] Add 1.4g of Tween 80 and 13.6g of Span 80 into 90g of white oil, pass N under stirring condition 2 Deoxygenation for half an hour, the oil phase was prepared for use; 10gAlCl 3 Add to 130g water and fully dissolve to make AlCl 3 aqueous solution, then add 28gMAPS and 28gDMAM to AlCl 3 In the aqueous solution, stir to fully dissolve it; transfer the oil phase to the reactor, add the water phase to the oil phase dropwise while stirring, and stir for half an hour to obtain an emulsification system; add 0.2g potassium persulfate to the emulsification system, wait After fully dissolved, pass N 2 Deoxygenation for half an hour, while raising the temperature to 50 ° C, and reacting for 2 hours to obtain an intermediate product; then dissolving 6 g of cationic polyamine 3 in 20 g of deionized water to prepare a cationic polyamine solution, and then adding the cationic polyamine solution to the intermediate product, Mix evenly, and at the same time raise the temperature to 60...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com