Modified positive electrode material for lithium iron phosphate battery and preparation method of modified positive electrode material and lithium-ion battery

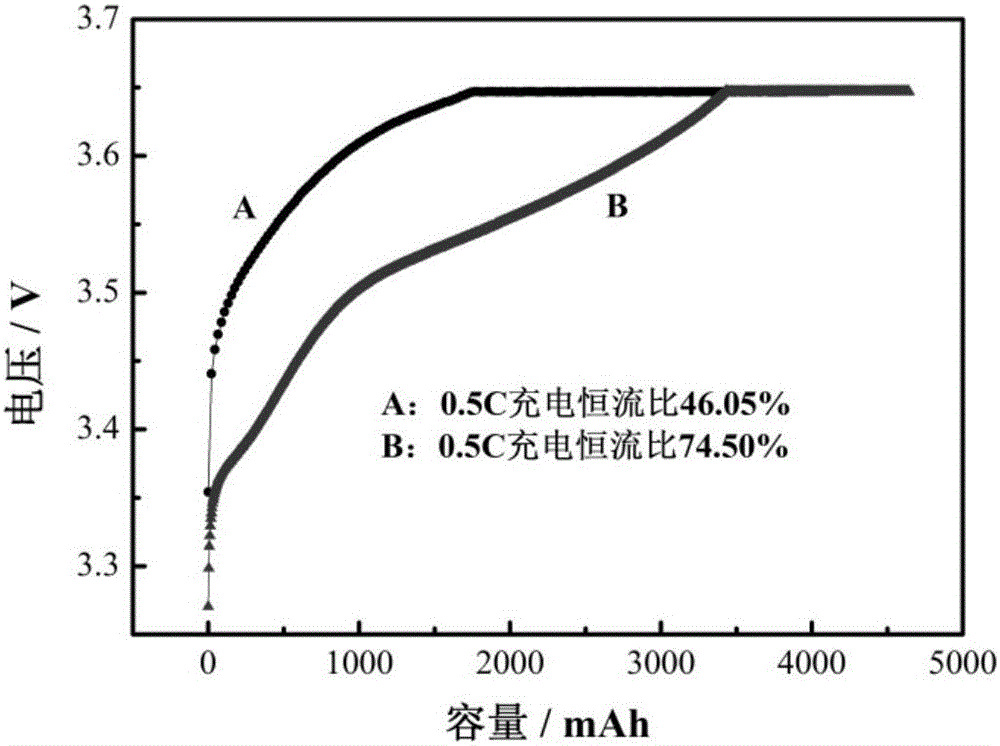

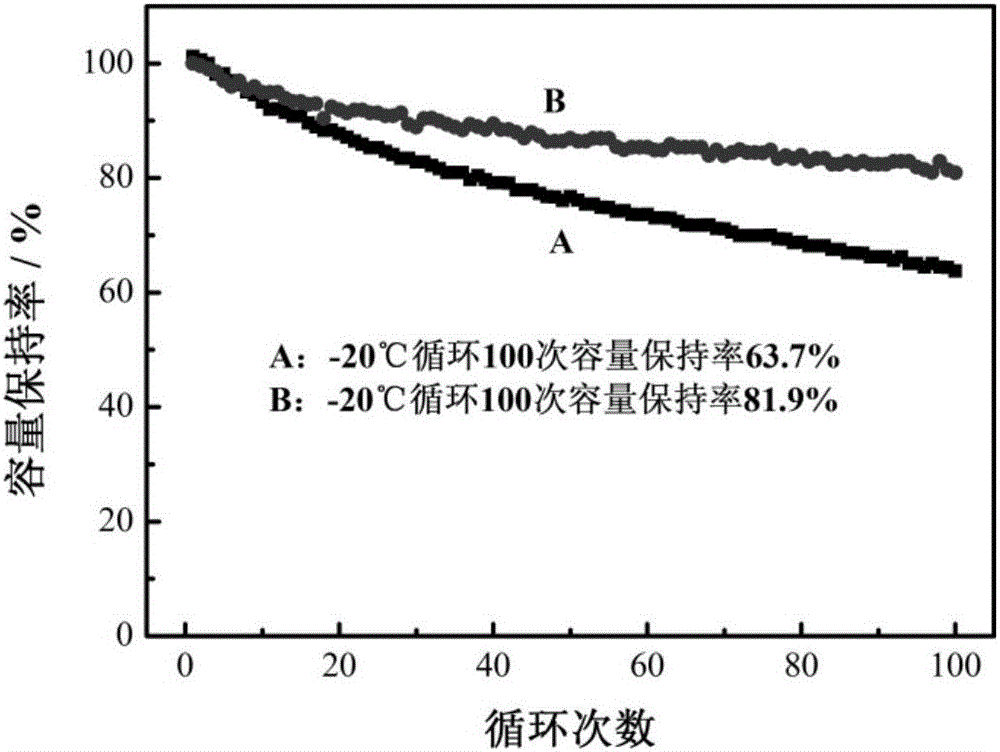

A technology of lithium iron phosphate battery and positive electrode material, applied in battery electrodes, batteries, secondary batteries, etc., can solve problems such as poor charge-discharge performance and cycle performance, improve battery electrochemical performance, reduce battery internal resistance, The effect of reducing drag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] ① Weigh 18g of ethylenediamine and dissolve it in 80ml of deionized water, add 23.1g of zirconium oxynitrate, stir ultrasonically for 30min, filter with suction, and dry the obtained solid in an air drying oven at 80°C for 12h to obtain a white solid, that is, zirconium-doped Carbon precursors.

[0034] ② Place the zirconium-doped carbon material precursor prepared in step ① in a place filled with N 2 In a tube furnace, the temperature was raised to 320 °C at a heating rate of 5 °C / min, kept for 5 h, and then cooled to room temperature at a cooling rate of 5 °C / min to obtain a zirconium-doped carbon material.

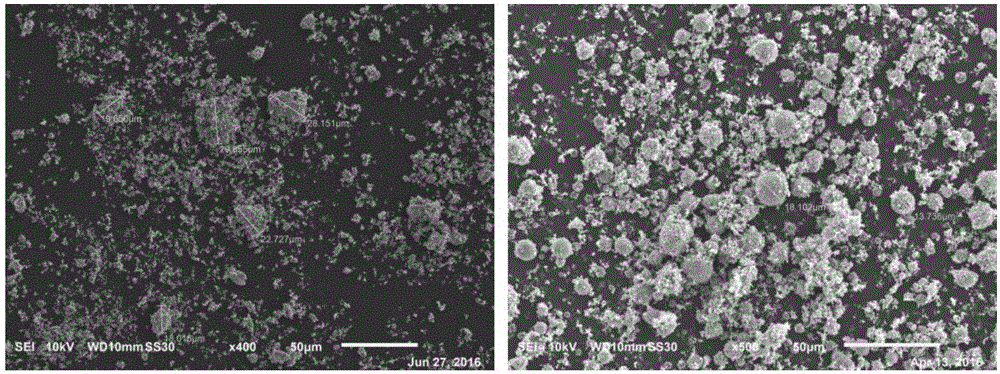

[0035] ③ Disperse 12.5g of lithium iron phosphate and 0.25g of the zirconium-doped carbon material obtained in step ② in deionized water, transfer the resulting solution to a high-pressure reactor, place the reactor in a dynamic reactor, and adjust The rotation speed of the reactor was 20r / min, the mixture was subjected to hydrothermal treatment at 140°C for 14h...

Embodiment 2

[0037] ①Weigh 31g of diethylenetriamine and dissolve it in 80ml of deionized water, add 42.9g of zirconium nitrate pentahydrate, stir ultrasonically for 20min, filter with suction, and dry the obtained solid in an air drying oven at 60°C for 14h to obtain a white solid. That is, zirconium-doped carbon material precursor.

[0038] ② Place the zirconium-doped carbon material precursor prepared in step ① in a place filled with N 2 In a tube furnace, the temperature was raised to 300 °C at a heating rate of 3 °C / min, kept for 3 h, and then cooled to room temperature at a cooling rate of 5 °C / min to obtain zirconium-doped carbon materials.

[0039] ③ Disperse 12.5 g of lithium iron phosphate and 0.25 g of the zirconium-doped carbon material obtained in step ② in deionized water, and transfer the resulting solution to an autoclave. The reactor was placed in a dynamic reactor, the rotation speed of the reactor was adjusted to 15 r / min, and the mixture was subjected to hydrothermal t...

Embodiment 3

[0041] ① Weigh 43.9g of triethylenetetramine and dissolve it in 80ml of deionized water, add 32.7g of zirconium isopropoxide, stir ultrasonically for 30min, filter with suction, and dry the obtained solid in an air drying oven at 80°C for 12h to obtain a white solid. That is, zirconium-doped carbon material precursor.

[0042]② Place the zirconium-doped carbon material precursor prepared in step ① in a place filled with N 2 In a tube furnace, the temperature was raised to 320 °C at a heating rate of 5 °C / min, kept for 5 h, and then cooled to room temperature at a cooling rate of 5 °C / min to obtain a zirconium-doped carbon material.

[0043] ③ Disperse 12.5 g of lithium iron phosphate and 0.25 g of the zirconium-doped carbon material obtained in step ② in deionized water, and transfer the resulting solution to an autoclave. The reactor was placed in a dynamic reactor, the rotation speed of the reactor was adjusted to 20 r / min, and the mixture was subjected to hydrothermal trea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com