Evaluation device and evaluation method an electrocatalyst property used for a solid polymer electrolyte fuel cell and water electrolysis

A solid polymer and evaluation device technology, which is applied to measuring devices, material analysis by electromagnetic means, and material analysis, can solve the problems of complex influencing factors, many catalysts, and cumbersome processes, and achieve low cost, convenient operation, and reduced wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

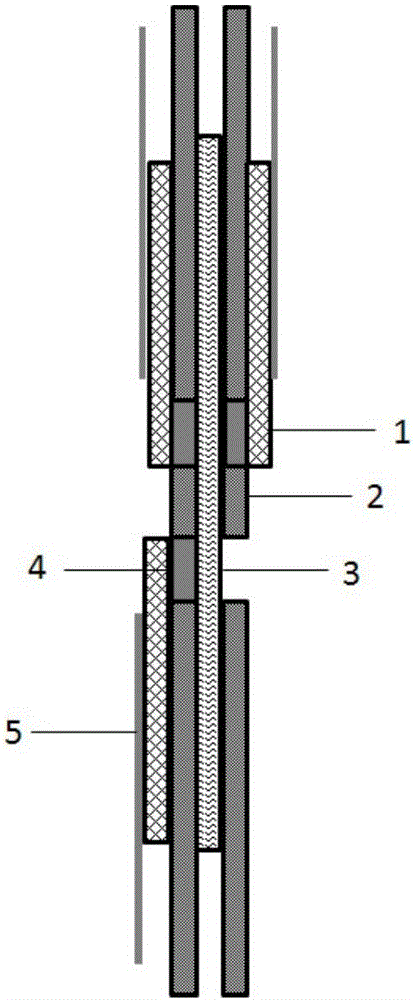

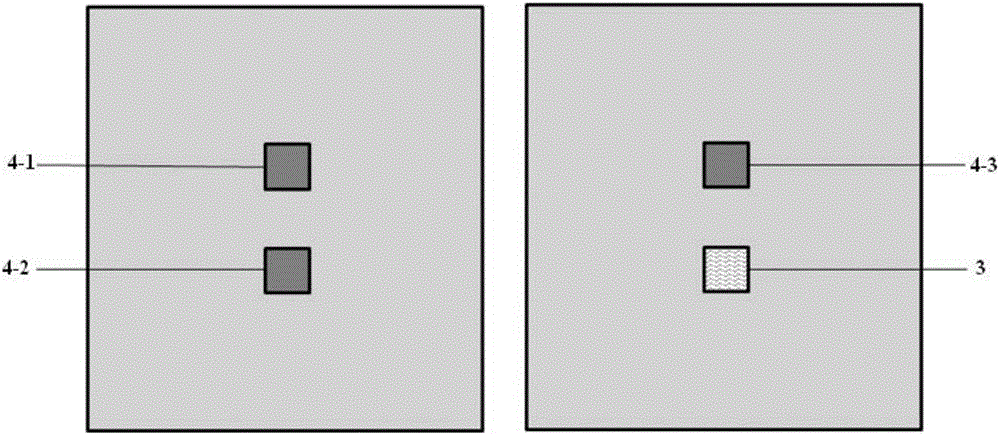

[0043] a. Preparation of Electrolyte Substrate

[0044]Carve holes of the required electrode shape and area on two hydrophobic basement membrane materials 2, and then heat-press the hydrophobic basement membrane material 2 on both sides of the ion-exchange membrane 3 to form electrolyte substrates. The hot-pressing pressure is 10MPa, and Pressing time is 180s;

[0045] b. prepare catalyst slurry for working electrode, counter electrode and reference electrode;

[0046] c. Preparation of solid electrolyte electrode 8

[0047] Add the prepared catalyst slurry of the working electrode, the counter electrode and the reference electrode dropwise to the corresponding electrode position, cut the current collector into the desired shape, heat press it on the corresponding electrode respectively, and then connect the current collector with conductive glue 1 and the wire 5 are made into a solid electrolyte electrode 8;

[0048] d. Electrocatalytic performance test

[0049] The prepa...

Embodiment 1

[0052] Embodiment 1 tests oxygen reduction reaction in Nafion 115 electrolyte

[0053] a. Preparation of electrolyte substrate: Use 30 μm thick polytetrafluoroethylene film as the electrolyte substrate material, cut it into a shape of 6cm*6cm, and then carve two holes of 5mm*5mm in the middle, and the gap between the two The spacing is controlled at 5mm; then the prepared PTFE film is hot-pressed on both sides of the clean Nafion 115 film, the hot-pressing pressure is 10MPa, and the hot-pressing time is 180s.

[0054] b. The catalyst slurry of the working electrode, the counter electrode and the reference electrode is the same, and its preparation method is: weigh 5 mg of 20% Pt / C catalyst with a primary balance, add 50 μL of 5% Nafion solution and 950 μL of ethanol, and ultrasonically mix the solution to Pt / C is uniformly dispersed in the solution.

[0055] c. Preparation of solid electrolyte electrode: Add the prepared catalyst slurry dropwise to the corresponding electrod...

Embodiment 2

[0057] Example 2 Methanol Electrooxidation Reaction Tested in Nafion 115 Electrolyte

[0058] a. Preparation of electrolyte substrate: Use 30 μm thick polytetrafluoroethylene film as the electrolyte substrate material, cut it into a shape of 6cm*6cm, and then carve two holes of 5mm*5mm in the middle, and the gap between the two The spacing is controlled at 5mm; then the prepared PTFE film is hot-pressed on both sides of the clean Nafion 115 film, the hot-pressing pressure is 10MPa, and the hot-pressing time is 180s.

[0059] b. 20% Pt10% Ru / C is used as the catalyst for the working electrode, and 20% Pt / C is used as the catalyst for the counter electrode and reference electrode. solution and 950 μL ethanol, and ultrasonically mix the solution until the catalyst is evenly dispersed in the solution.

[0060] c. Preparation of solid electrolyte electrodes: Add the prepared catalyst slurry dropwise to the corresponding electrode positions, and add 5 μL of 20% Pt10% Ru / C catalyst ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com