Method for measuring surface morphology to detect internal defects of interlayer of double-layer or multi-layer film

A technology for measuring surfaces and multilayer films. It is used in optical testing for flaws/defects, measuring devices, and material analysis by optical means. low threshold effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

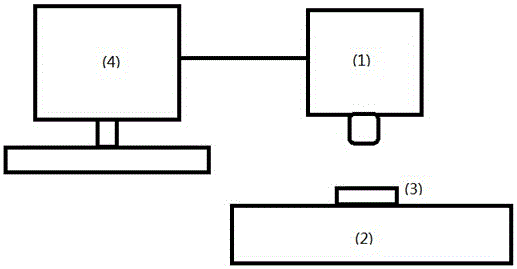

[0030] Specific implementation mode one: as figure 1 As shown, this embodiment provides a device for measuring surface topography to detect internal defects between layers of double-layer and multi-layer thin films. , the specific detection steps are as follows:

[0031] 1. Place the tested part 3 on the low-temperature heating platform 2, the surface topography detection device 1 is located above the tested part 3, and record the placement position of the tested part 3 on the low-temperature heating platform;

[0032] 2. Adjust and record various parameters of the surface topography detection device 1, and use this as a reference parameter to detect the tested part 3;

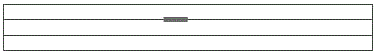

[0033] 3. Set the low-temperature heating platform 2 to room temperature, measure and record the surface morphology of the tested part 3;

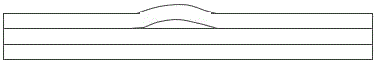

[0034] 4. Set the low-temperature heating platform 2 for constant temperature heating, measure and record the surface morphology of the tested part 3, and turn off the l...

specific Embodiment approach 2

[0050] Specific implementation mode 2: This implementation mode provides a method for measuring surface topography to detect internal defects between double-layer and multi-layer film layers, and the specific implementation steps are as follows:

[0051] 1. The tested part is composed of nickel film and substrate;

[0052] 2. Use an optical 3D surface topography detection device for measurement, and its parameters are as follows: 5x objective lens, 1.76μm×1.76μm pixel size, 410nm vertical resolution, 2.2μm lateral resolution, and the ambient temperature of the lens is required to be 45°C ;

[0053] 3. Place the tested part on the low-temperature heating platform, the surface topography detection device is located above the tested part, and record the placement position of the tested part on the low-temperature heating platform;

[0054] 4. Set the low-temperature heating platform to room temperature, and use the surface topography detection device to measure the 3D topography...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com