Central kitchen smoke dust collecting vapor generator integrated machine

A technology for steam generators and dust collection, applied in steam generation, steam generation devices, oil fume removal, etc., can solve the problems of inability to achieve dust magnetic field accumulation and poor smoke collection effect, and achieve easy promotion, low cost, and applicable strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

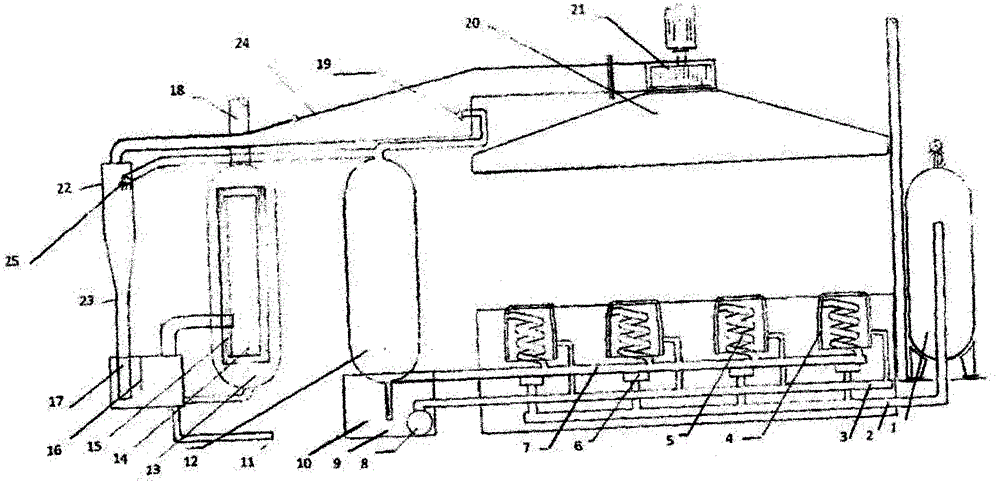

[0021] figure 1 It is a schematic diagram of the side view structure for the implementation of the present invention figure 1 .In this embodiment, the steam is to use the heat of cooking to heat the water pump 8, through the pipeline 3, supplied to the stove interlayer 4, boil the tender water of the spiral water pipe 5 connected to the boiler interlayer, and pass through the pipeline. 7. The boiled water vapor is sent to the water-gas separation steam tank 12 to form a steam tank 12. The lower end of the gas-water separation tank 12 is provided with a thin leaking pipe 10. There is a water tank 9 at the bottom as a support to collect the separated water; when the smoke is collected by the smoke collection hood After 20 is collected, under the action of blower fan 21, smoke is sent to gradually narrowed smoke mixing pipes 24 and 22, and steam is also sprayed from nozzles 19 and 25 in the pipes to mix with smoke. When the mixing head 23 gradually becomes thinner, the mixing de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com