Induction type double-layer fireproof roller shutter

A fire-proof rolling shutter and double-layer technology, applied in the field of rolling shutters, can solve the problems of poor fire-proof performance and bulkiness, and achieve the effect of improving fire-proof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

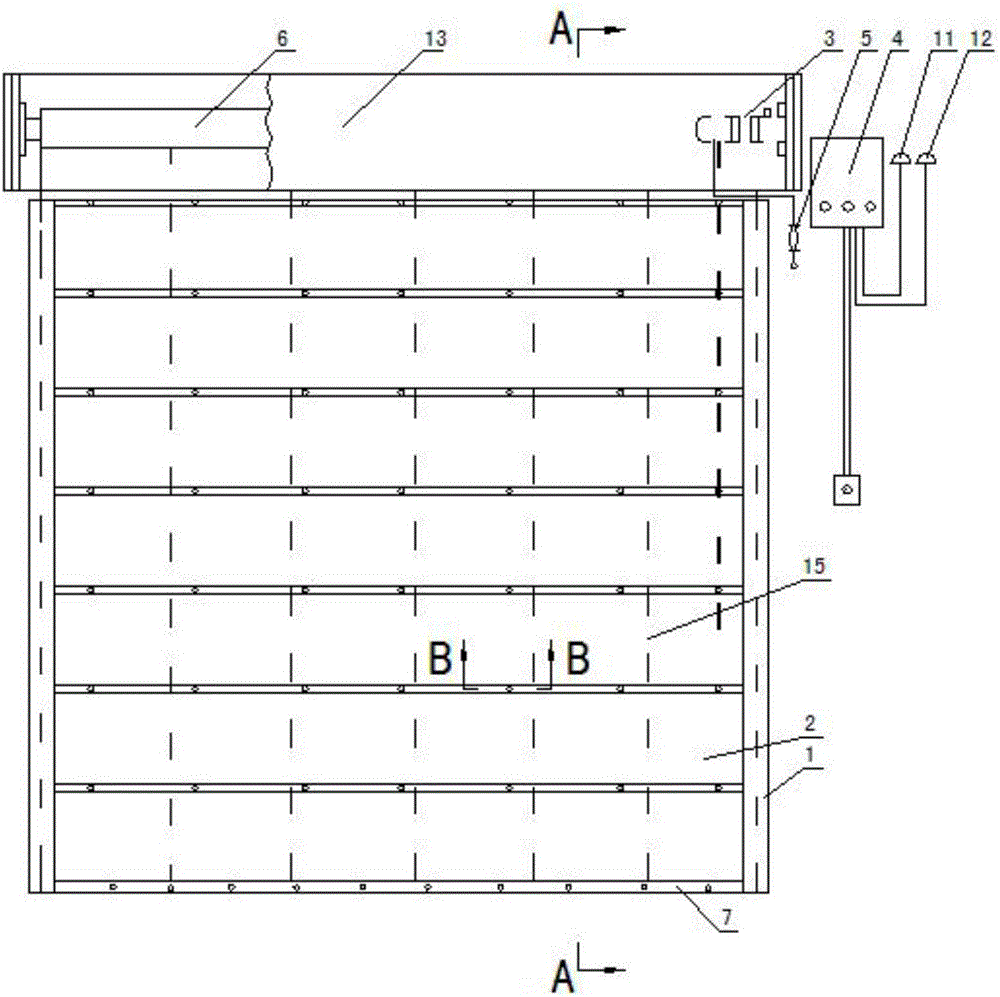

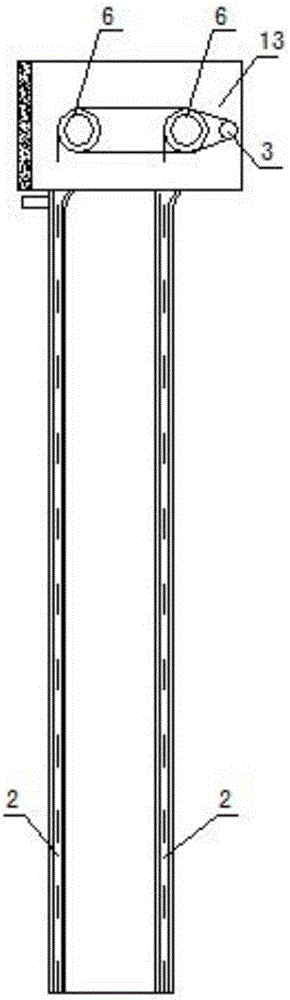

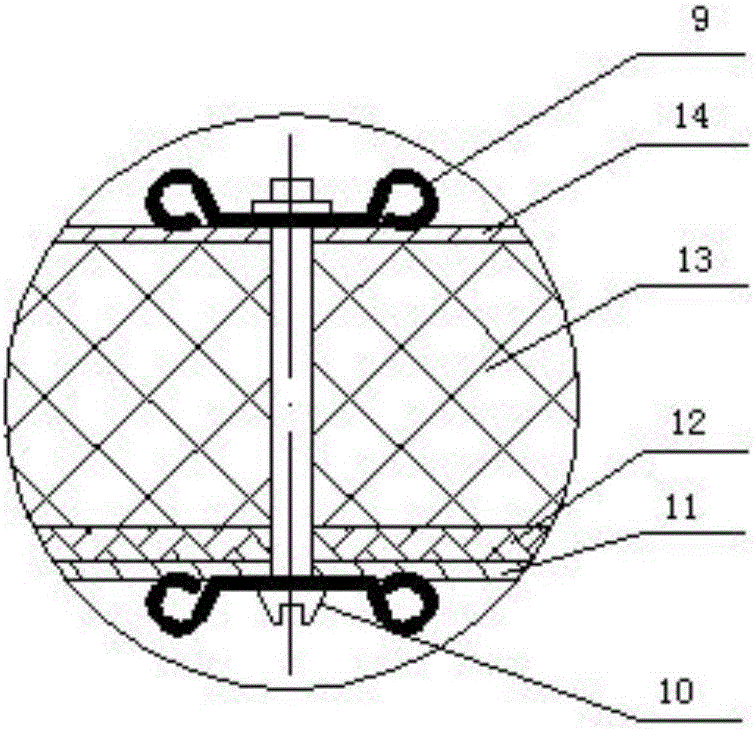

[0018] The induction type double-layer fireproof roller shutter shown in the attached drawing includes guide rail 1, curtain surface 2, roller door machine 3, roller shutter controller 4, reel 6, box body 13, point-type photoelectric smoke detector 11, temperature controller Release device 5, point-type temperature-sensitive fire detector 12, several steel wire ropes 15, in the present embodiment, the curtain surface 2 is made of fireproof glass fiber decorative cloth 11, fireproof cloth 12, fireproof blanket 13 for fireproof rolling shutter, fireproof aluminum foil The cloth 14 is compounded sequentially, and is fastened by several bolts 10 and nuts 9 . The roller shutter controller 4 is arranged outside the box body 13 .

[0019] The box body 13 is provided with a rolling door machine 3 and two reels 6. The reels 6 are placed flat, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com