Cold in-place recycling construction method

A construction method and cold recycling technology, which is applied in roads, road repairs, roads, etc., can solve problems such as insufficient cement consumption and the impact of asphalt pavement regeneration, and achieve the effects of reducing pollution, reducing dust, and ensuring actual consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A construction method for in-situ cold recycling, comprising the steps of:

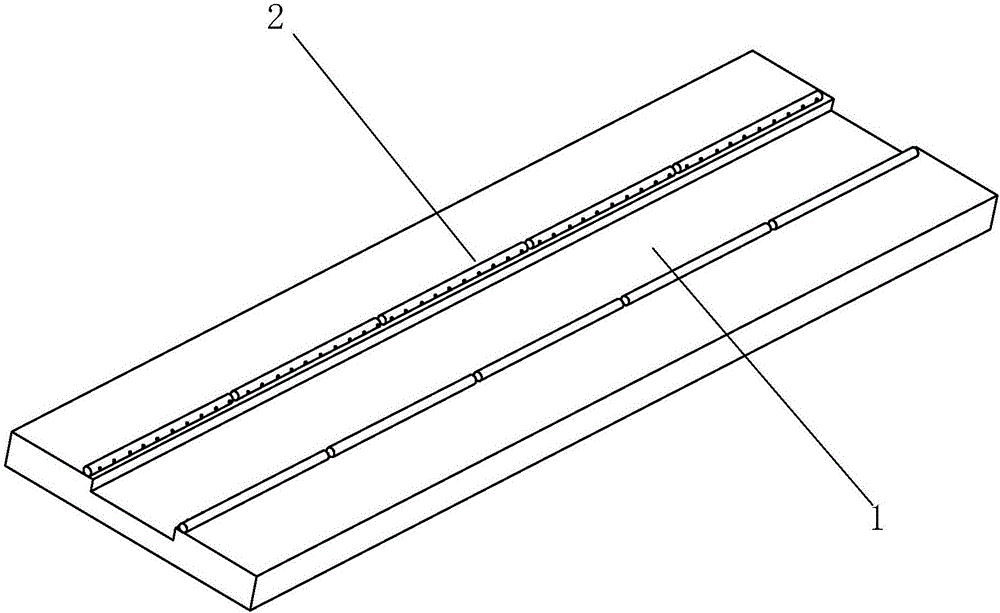

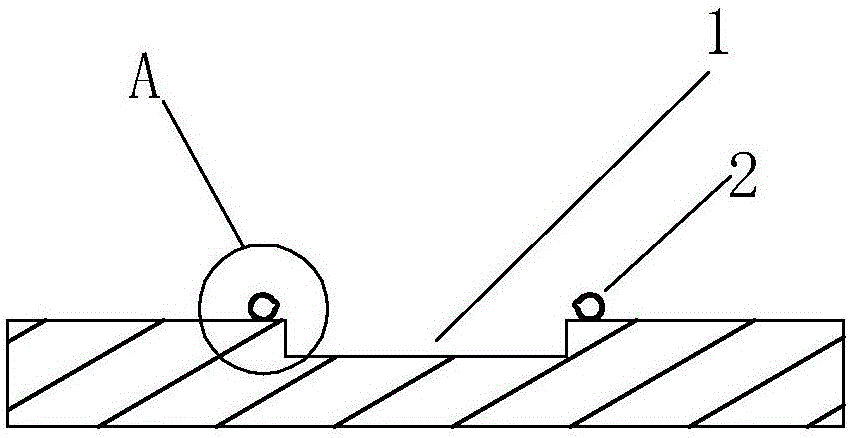

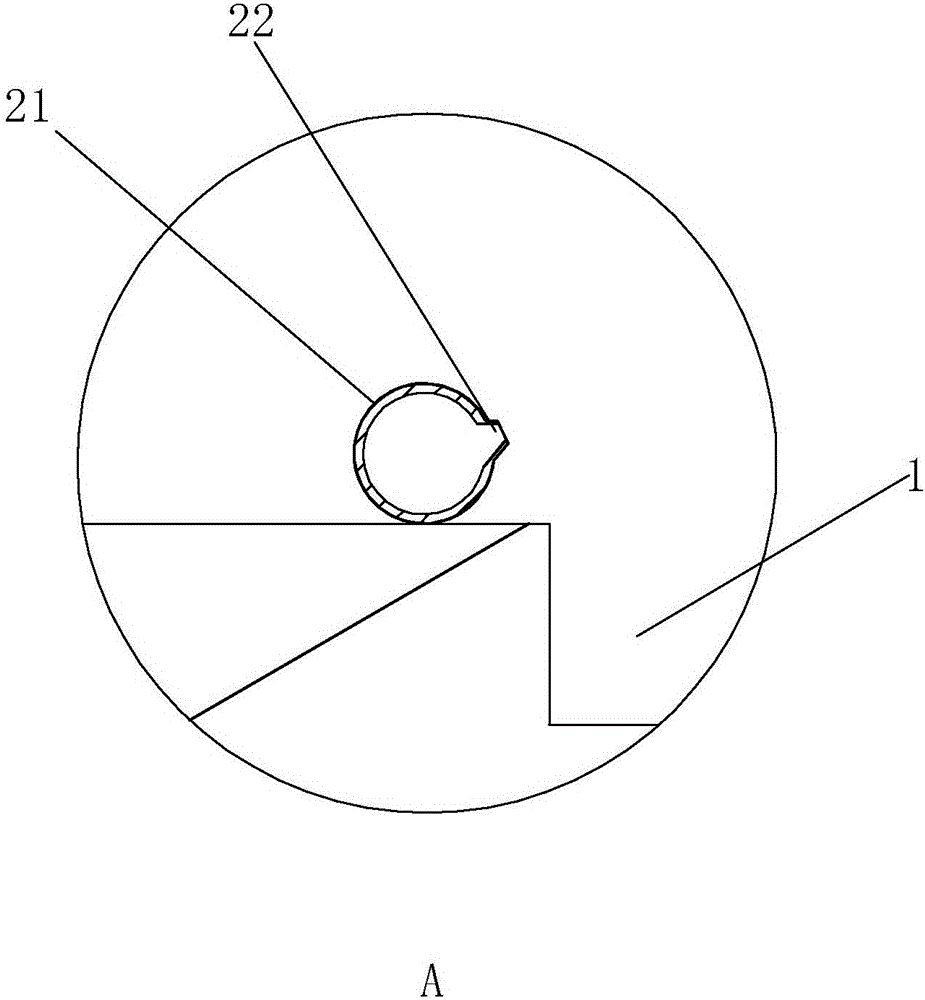

[0039]S1. Construction preparation: firstly carry out road sealing and cleaning work on the old road surface 1 to be treated. Although several atomizing devices 2 are arranged on both sides of the road surface to be processed, the atomizing devices 2 on both sides of the road are arranged facing each other. The coverage of each atomizing device 2 in length is 50m and covers the whole road in the length direction. The nozzles of the atomizing devices 2 on both sides of the road are relatively arranged, and they all spray upwards obliquely, forming an angle of 30 degrees with the horizontal plane;

[0040] S2. First calculate the horizontal and vertical distance between each bag of cement according to the weight of the cement bag, mark it on the road, then place each bag of cement at the corresponding marking point, and then spread the cement evenly with a scraper. The paving area of bags of c...

Embodiment 2

[0045] A construction method for in-situ cold recycling, comprising the steps of:

[0046] S1. Construction preparation: firstly carry out road sealing and cleaning work on the old road surface 1 to be treated. Although several atomizing devices 2 are arranged on both sides of the road surface to be processed, the atomizing devices 2 on both sides of the road are arranged facing each other. The coverage of each atomizing device 2 in length is 50m and covers the whole road in the length direction. The nozzles of the atomizing devices 2 on both sides of the road are arranged oppositely, and they all spray upward obliquely, forming an angle of 45 degrees with the horizontal plane;

[0047] S2. First calculate the horizontal and vertical distance between each bag of cement according to the weight of the cement bag, mark it on the road, then place each bag of cement at the corresponding marking point, and then spread the cement evenly with a scraper. The paving area of bags of c...

Embodiment 3

[0051] A construction method for in-situ cold recycling, comprising the steps of:

[0052] S1. Construction preparation: firstly carry out road sealing and cleaning work on the old road surface 1 to be treated. Although several atomizing devices 2 are arranged on both sides of the road surface to be processed, the atomizing devices 2 on both sides of the road are arranged facing each other. The coverage of each atomizing device 2 in length is 50m and covers the whole road in the length direction. The nozzles of the atomizing devices 2 on both sides of the road are arranged oppositely, and they all spray upwards obliquely, forming an angle of 60 degrees with the horizontal plane;

[0053] S2. First calculate the horizontal and vertical distance between each bag of cement according to the weight of the cement bag, mark the road, then place each bag of cement at the corresponding marking point, and then spread the cement evenly with a scraper, every The paving area of bags of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com