Device and method for testing oiling performance of cellulose acetate tow

A technology of cellulose acetate tow and testing device, applied in fiber processing, filament generation, filament/thread forming, etc., can solve the problems of expensive equipment and high technical requirements of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

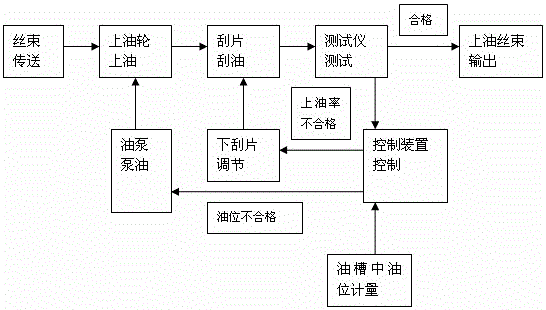

[0034] Such as figure 2 The test device for the oiling performance of acetate fiber tow has an oil pump 12, an oil inlet conduit 13, and an oil tank 11 arranged in sequence according to the flow direction of the oil agent, and an oil tanker 5 next to the oil tanker 5 arranged in sequence according to the direction of transmission of the tow 1. The godet 2 on one side, the oiler 5, the godet 2 next to the other side of the oiler 5, the output roller 9; the oil tank 11 is filled with oil agent, and the oil tank 11 is connected with an oil level metering device 19. The included angle between the shaft center of the upper oil tanker 5 and the center of the godet 2 next to both sides is 150°-160°. There is a cylindrical capacitance tester 8 with a hole structure inside between the godet 2 and the output roller 9 next to the other side of the upper oil tanker 5; there is an upper scraper close to the upper oil tanker where the tow enters the upper oil tanker 5 The sheet 3 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com