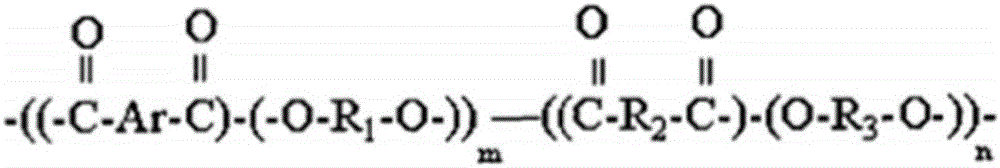

Aromatic polyester-aliphatic polyester block copolyester and preparing method thereof

An aromatic polyester and polyester block technology, applied in the polymer field, can solve the problem of little contribution to the dimensional stability of polyester fibers, and achieve good product quality stability, low glass transition temperature, and large disperse dyes. Effect of Molecular Diffusion Coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Prepare aromatic polyester-aliphatic polyester block copolyester according to the preparation method provided by the invention, the steps are as follows:

[0063] (1) adding an appropriate amount of catalyst to a mixture of terephthalic acid and ethylene glycol with a molar ratio of 1:1.15 to prepare a slurry;

[0064] (2) The slurry prepared in step (1) is continuously added to the esterification system composed of the first vertical esterification kettle and the second vertical esterification kettle for esterification reaction, and the reaction temperature of the first esterification kettle is 265°C, the reaction pressure is 200kPa, the reaction temperature of the second esterification tank is 270°C, and the reaction pressure is 150kPa. When the degree of polymerization of the ethylene terephthalate oligomer reaches 6, the oligomer is continuously and stably extracted from the esterification tank by the oligomer pump;

[0065] (3) After passing the ethylene terephtha...

Embodiment 2

[0069] Prepare aromatic polyester-aliphatic polyester block copolyester according to the preparation method provided by the invention, the steps are as follows:

[0070] (1) adding an appropriate amount of catalyst to a mixture of terephthalic acid and ethylene glycol with a molar ratio of 1:1.15 to prepare a slurry;

[0071] (2) The slurry prepared in step (1) was continuously added to an esterification system composed of a vertical esterification tank for esterification reaction, wherein the reaction temperature of the esterification tank was 250° C. and the reaction pressure was 200 kPa. When the degree of polymerization of ethylene terephthalate reaches 2, the oligomer is continuously and stably extracted from the esterification kettle by the oligomer pump;

[0072] (3) After the ethylene terephthalate oligomer prepared in step (2) is adjusted to 220°C through a heat exchanger, it is mixed with polysuccinic acid-1,2- The propylene glycol ester polyol is mixed evenly by th...

Embodiment 3

[0076] Prepare aromatic polyester-aliphatic polyester block copolyester according to the preparation method provided by the invention, the steps are as follows:

[0077] (1) Add an appropriate amount of catalyst to a mixture of terephthalic acid and ethylene glycol with a molar ratio of 1:2 to prepare a slurry;

[0078] (2) The slurry prepared in step (1) was continuously added to an esterification system composed of a vertical esterification tank for esterification reaction, wherein the reaction temperature of the esterification tank was 240° C. and the reaction pressure was 100 kPa. When the degree of polymerization of ethylene terephthalate reaches 1, the oligomer is continuously and stably extracted from the esterification tank by the oligomer pump;

[0079] (3) After passing the ethylene terephthalate oligomer prepared in step (2) through a heat exchanger to adjust the temperature to 250° C. Alcohol ester polyols are uniformly mixed through a tubular static mixer, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com