Controlled-release coated urea special for super grain rice and preparation method thereof

A technology of granular urea and special packaging, which is applied in the field of super-large granular rice special-coated controlled-release urea and its preparation, which can solve the problems of affecting crop root growth, improper fertilization methods, reducing crop yield and quality, etc., and achieve improved soil nutrient levels , save labor input, improve the effect of soil and water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

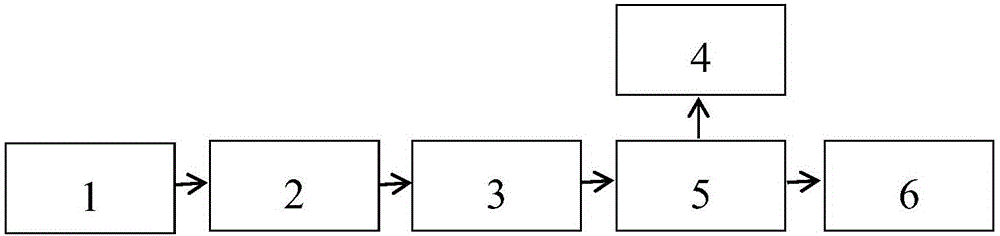

Method used

Image

Examples

Embodiment 1

[0028] First mix the granular or powdered urea raw material and the activated humic acid accounting for 5% of the mass ratio to obtain the urea raw material A; extrude the urea raw material A with an extruder under a pressure of 10T to form super-large granular spherical urea B, and the weight of B is Within the scope of 3g ± 0.1g, the diameter is 30mm; then use the coating material C to face the urea particle coating on the fluid bed (the components of the coating material are by weight ratio: castor oil 14.4%, elastomer polyether polyol 35% , polyphenylcyanate 50%, carbon nanotube 1‰, nano-silicon dioxide 5‰), the coating material C which accounts for 1% by weight of the fertilizer D is fully mixed with the fertilizer on the fluid bed until it solidifies Take out the urea fertilizer to obtain super-large-grain rice-coated controlled-release urea D; after weighing, the weight of the fertilizer increases by 0.9%-1%, which is the amount of its coating. Let it stand for 24 hours ...

Embodiment 2

[0030] First mix the granular or powdered urea raw material with its mass of 3% activated humic acid to obtain urea raw material A; extrude the urea raw material A with an extruder under a pressure of 6T to form super-large granular spherical urea B, and the weight of B is 2g±0.1 In the range of g, the diameter is 20mm, then use castor oil 20% by weight, elastomer polyether polyol 34.6%, polyphenylcyanate 45%, carbon nanotube 2‰ and nano silicon dioxide 2‰ As the coating material C to B coating, the coating material C accounting for 1.5% by weight of urea fertilizer B is fully mixed on the fluid bed until it is solidified, and then the urea fertilizer is taken out, that is, the special coating controlled release of super-large grain rice is obtained Urea D: After weighing, the mass ratio of urea fertilizer D increases by 1.4%-1.5%, which is its coating amount. Let it stand for 24 hours until it is completely solidified to measure the fertilizer release rate. The release period ...

Embodiment 3

[0032]First mix the granular or powdered urea raw material with 1% activated humic acid of urea quality to obtain urea raw material A; extrude the urea raw material A with an extruder under a pressure of 2T to form super-large spherical urea B, and the weight of B is 1g± In the range of 0.1g, the diameter is 10mm, then use the amount of castor oil 24.3% by weight, elastomer polyether polyol 20%, polyphenylcyanate 55%, carbon nanotube 3‰ and nano silicon dioxide 4‰ as the coating material C to B coating, the coating material C accounting for 0.5% by weight of urea fertilizer B is fully mixed on the fluid bed until it is solidified, and then the urea fertilizer is taken out to obtain a special coating for super-large grain rice Controlled-release urea D: After weighing, the mass ratio of urea fertilizer increases by 0.4%-0.5%, which is its coating amount, and it is allowed to stand for 24 hours until it is completely solidified to measure the fertilizer release rate, and the rele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com