High-ductility cement based composite material and preparation method thereof

A composite material and cement-based technology, which is applied in the field of coatings, can solve the problems of compressive strength decline and imperfection, and achieve the effects of dry shrinkage, good carbonation resistance and low alkali content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A high-ductility cement-based composite material, comprising 5% of A component, 10% of B component and 85% of C component, the A component is an emulsion, by weight percentage,

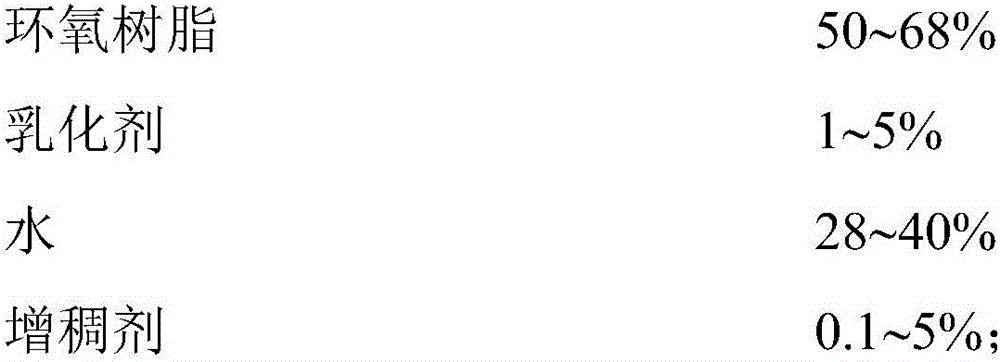

[0057] A component includes:

[0058]

[0059] The B component includes:

[0060] Water-based epoxy curing agent 20%

[0061] Defoamer 1%

[0062] water 79%;

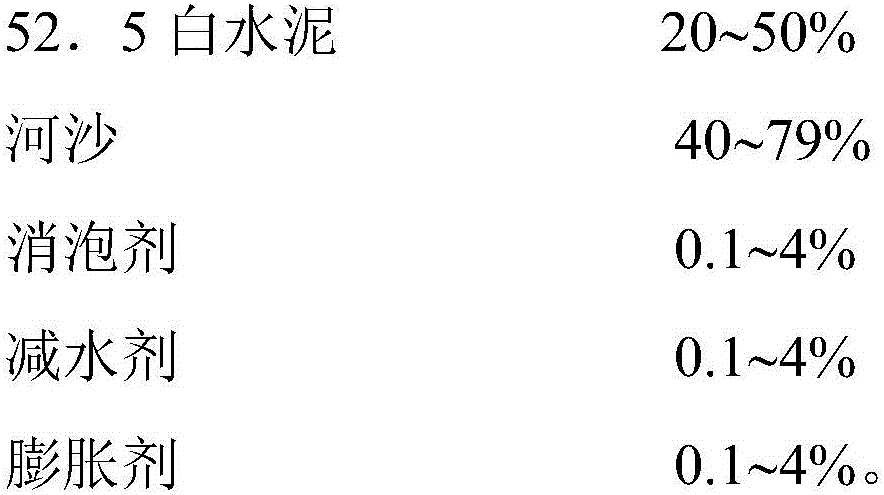

[0063] The C component includes:

[0064]

[0065] The solid content in component A is 70%. The epoxy resin is a mixture of bisphenol A epoxy resin and epoxy diluent. The emulsifier is an octylphenol polyoxyethylene ether series emulsifier, and the thickener is a polyurethane emulsion stabilizer. The water-based epoxy curing agent in component B is a water-based phenalkamine epoxy curing agent. River sand is 30-40 mesh mixed sand. Dry powder defoamer is a special defoamer for dry powder mortar. It is a non-ionic surfactant suitable for dry cement mortar containing liquid hydrocarbons, polyethylene glycol and inorganic carri...

Embodiment 2

[0067] A high-ductility cement-based composite material, comprising 10% of A component, 10% of B component and 80% of C component, by weight percentage,

[0068] A component includes:

[0069]

[0070] The B component includes:

[0071] Waterborne epoxy curing agent 39%

[0072] Defoamer 0.1%

[0073] Water 60.1%;

[0074] The C component includes:

[0075]

[0076] The solid content in component A is 50%. The epoxy resin is a mixture of bisphenol A epoxy resin and epoxy diluent. The emulsifier is an octylphenol polyoxyethylene ether series emulsifier, and the thickener is a polyurethane emulsion stabilizer. The water-based epoxy curing agent in component B is a water-based phenalkamine epoxy curing agent. River sand is 80-100 mesh mixed sand. Dry powder defoamer is a special defoamer for dry powder mortar. It is a non-ionic surfactant suitable for dry cement mortar containing liquid hydrocarbons, polyethylene glycol and inorganic carriers. The water reducer is ...

Embodiment 3

[0078] A high ductility cement-based composite material, comprising 7% of A component, 11% of B component and 82% of C component, by weight percentage,

[0079] A component includes:

[0080]

[0081]

[0082] The B component includes:

[0083] Water-based epoxy curing agent 30%

[0084] Defoamer 0.5%

[0085] Water 69.5%;

[0086] The C component includes:

[0087]

[0088] The solid content in component A is 60%. The epoxy resin is a mixture of bisphenol A epoxy resin and epoxy diluent. The emulsifier is an octylphenol polyoxyethylene ether series emulsifier, and the thickener is a polyurethane emulsion stabilizer. The water-based epoxy curing agent in component B is a water-based phenalkamine epoxy curing agent. River sand is 80-100 mesh mixed sand. Dry powder defoamer is a special defoamer for dry powder mortar. It is a non-ionic surfactant suitable for dry cement mortar containing liquid hydrocarbons, polyethylene glycol and inorganic carriers. The water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com