Environment-friendly compound admixture for architectural decoration engineering and preparation method thereof

A technology for building decoration engineering and composite admixture, which is applied in the field of environment-friendly composite admixture for building decoration engineering and its preparation, can solve the problems affecting the economic benefits of iron and steel enterprises, pollute the environment, accumulation of steel slag, etc., and improve the hydration of steel slag. Reactive activity, increased reactivity, increased ability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

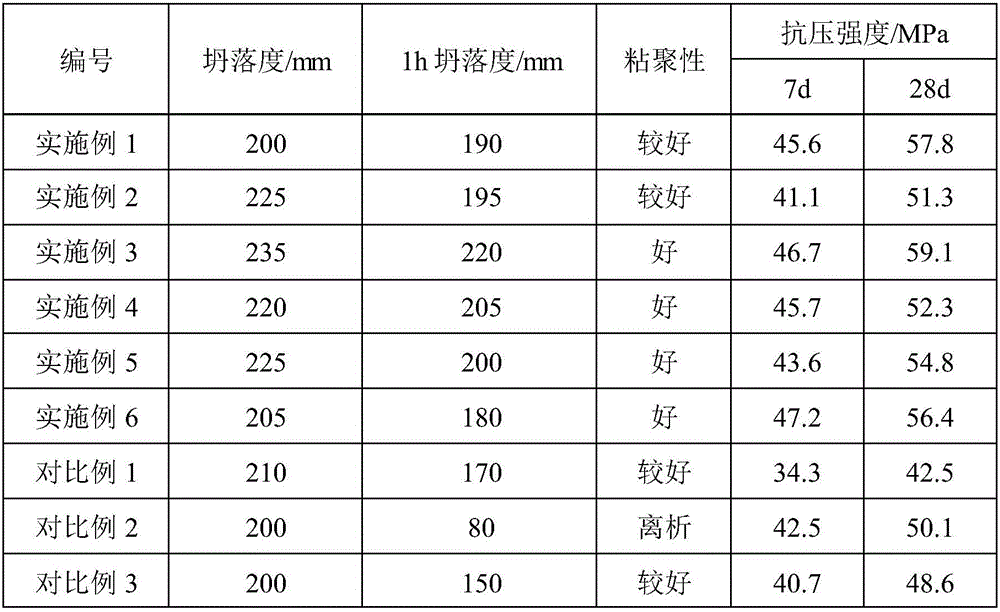

Examples

Embodiment 1

[0031] An environment-friendly composite admixture for building decoration engineering, which is composed of the following substances in weight percentage: 20wt% of steel slag, 1wt% of hydrotalcite, 0.05wt% of material layer stabilizing substance, 0.1wt% of magnesium fluorosilicate, and 0.1wt% of reinforcing substance %, fiber 0.1wt%, nano-alumina 1wt%, and the balance being slag.

[0032] The material layer stabilizing substance refers to calcium sucrose.

[0033] The said enhancing substance refers to sodium nitrate.

[0034] The fiber is coconut palm fiber.

[0035] Preparation method: Weigh the raw materials according to the above weight percentage, crush them through a crusher until the particle size is less than 5mm; mix the raw materials and send them to a vertical mill for grinding until the specific surface area is 420m 2 / kg, obtained the environment-friendly composite admixture for architectural decoration engineering.

Embodiment 2

[0037] An environment-friendly composite admixture for building decoration engineering, which is composed of the following substances in weight percentage: 30wt% of steel slag, 5wt% of hydrotalcite, 0.3wt% of material layer stabilizing substance, 0.2wt% of magnesium fluorosilicate, and 1wt% of reinforcing substance , 0.5 wt% of fiber, 5 wt% of nano-alumina, and the balance is slag.

[0038] The material layer stabilizing material is composed of calcium sucrose, polyacrylamide, polyoxyethylene alcohol and decaglycerol in a weight ratio of 1:1:1:1.

[0039] The reinforcing substance is composed of sodium nitrate, iminodiacetic acid and aluminum sulfate in a weight ratio of 2:1:2.

[0040] The fibers are composed of sisal fibers, ramie fibers and basalt fibers in a weight ratio of 1:1:3.

[0041] Preparation method: Weigh the raw materials according to the above weight percentage, and crush them through a crusher until the particle size is less than 5mm; mix the raw materials an...

Embodiment 3

[0043] An environment-friendly composite admixture for building decoration engineering, which is composed of the following substances in weight percentage: 24wt% of steel slag, 3wt% of hydrotalcite, 0.2wt% of material layer stabilizing substance, 0.12wt% of magnesium fluorosilicate, and 0.6wt% of reinforcing substance %, fiber 0.4wt%, nano-alumina 2wt%, and the balance being slag.

[0044] The material bed stabilizing substance is composed of polyoxyethylene alcohol and pentaglycerol in a weight ratio of 1:1.

[0045] The reinforcing substance is iminodiacetic acid.

[0046] The fiber is composed of coconut palm fiber and basalt fiber in a weight ratio of 2:1, and the fiber length is 1mm-3mm.

[0047] Preparation method: Weigh the raw materials according to the above weight percentage, and crush them through a crusher until the particle size is less than 5mm; mix the raw materials and send them to a vertical mill for grinding until the specific surface area is 450m 2 / kg, ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com