Normal pressure preparation method of aerosil by using nitrate

A silica and aerogel technology, applied in the direction of silica and silica, can solve the problems of industrial development restrictions, long time, high price, etc., and achieve the effect of wide application range, good utility and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

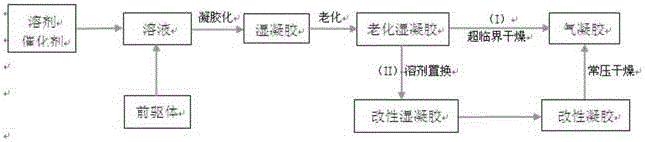

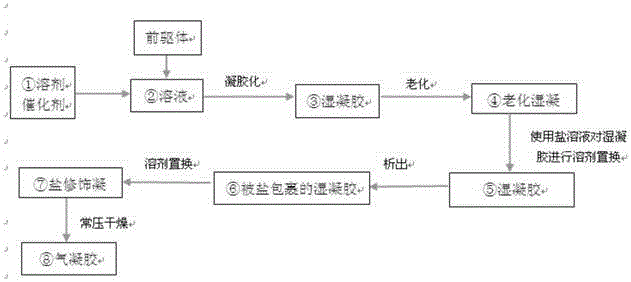

Method used

Image

Examples

Embodiment 1

[0055] Wet gel preparation stage:

[0056] The proportion of precursor catalyst solvent is as follows: (molar ratio)

[0057] ETOH:TEOS:H2O:DMF=1:2:1:0.5

[0058] Add ETOH (solvent), TEOS (precursor), and DMF (N-N dimethylformamide) into a 250ml double-necked flask, place it in an oil bath at 60°C, adjust the speed to 500 rpm, and stir magnetically in the oil bath for 10 minutes.

[0059] Join H 2 O, add concentrated hydrochloric acid (adjust the pH to about 3) and continue magnetic stirring in an oil bath at 60°C for 1h.

[0060] Move the solution in the flask to a 250ml beaker, drop in concentrated ammonia water (adjust the pH to about 7), adjust the rotation speed to 100, and let it stand until the sol gels.

[0061] aging stage:

[0062] Place the obtained wet gel in the mother liquor for aging, 24 hours each time, 2 times in total

[0063] Solvent exchange phase:

[0064] A certain amount of potassium nitrate was weighed and dissolved in a certain amount of deionize...

Embodiment 2

[0073] Wet gel preparation stage:

[0074] The proportion of precursor catalyst solvent is as follows: (molar ratio)

[0075] ETOH:TEOS:H2O:DMF=1:1:1:0.75

[0076] Add ETOH (solvent), TEOS (precursor), and DMF (N-N dimethylformamide) into a 250ml double-necked flask, place it in an oil bath at 60°C, adjust the speed to 500 rpm, and stir magnetically in the oil bath for 10 minutes.

[0077] Add H2O, add concentrated hydrochloric acid (adjust the pH to about 3) and continue magnetic stirring in an oil bath at 60°C for 1h.

[0078] Move the solution in the flask to a 250ml beaker, drop in concentrated ammonia water (adjust the pH to about 7), adjust the rotation speed to 100, and let it stand until the sol gels.

[0079] aging stage:

[0080] Place the obtained wet gel in the mother liquor for aging, 24 hours each time, 2 times in total

[0081] Solvent exchange phase:

[0082] A certain amount of potassium nitrate is weighed and dissolved in a certain amount of deionized wa...

Embodiment 3

[0091] Wet gel preparation stage:

[0092] The proportion of precursor catalyst solvent is as follows: (molar ratio)

[0093] ETOH:TEOS:H2O:DMF=1:6:3:0.75

[0094] Add ETOH (solvent), TEOS (precursor), and DMF (N-N dimethylformamide) into a 250ml double-necked flask, place it in an oil bath at 50°C, adjust the rotation speed to 700 rpm, and stir magnetically in the oil bath for 10 minutes.

[0095] Add H2O, add concentrated hydrochloric acid (adjust the pH to about 3) and continue magnetic stirring in an oil bath at 60°C for 1h.

[0096] Move the solution in the flask to a 250ml beaker, drop in concentrated ammonia water (adjust the pH to about 7), adjust the rotation speed to 100, and let it stand until the sol gels.

[0097] aging stage:

[0098] Place the obtained wet gel in the mother liquor for aging, 24 hours each time, 2 times in total

[0099] Solvent exchange phase:

[0100] A certain amount of potassium nitrate was weighed and dissolved in a certain amount of de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com