Selective ring-opening catalyst and preparation method thereof

A catalyst and selective technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of fast catalyst deactivation rate, low yield of monocyclic aromatic hydrocarbons, and poor ring-opening selectivity of polycyclic aromatic hydrocarbons, etc. problems, to achieve the effect of improving the ring-opening efficiency, delaying the inactivation rate, and inhibiting agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

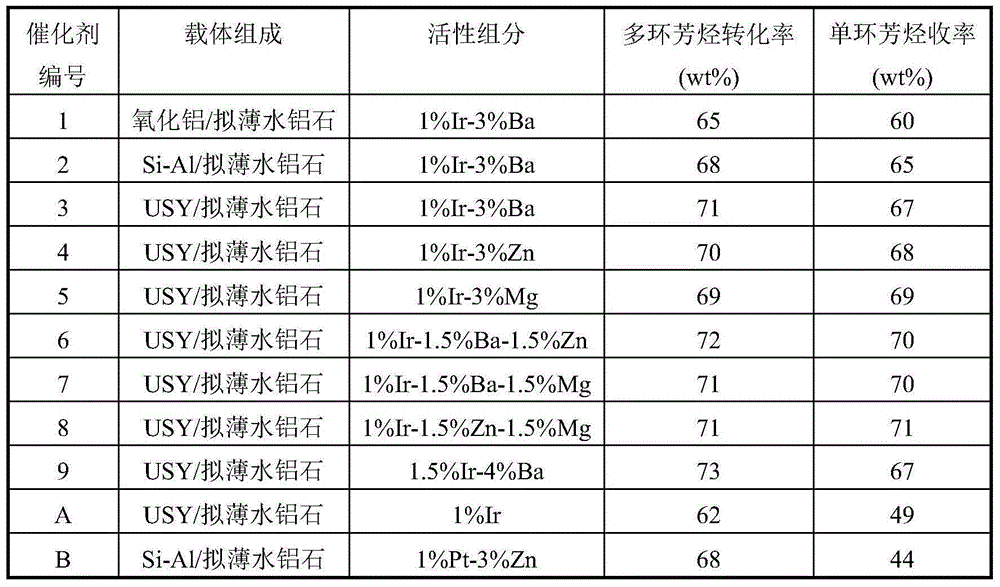

Examples

Embodiment 1

[0036] Add 70g large-pore pseudo-boehmite (commercially available) on a dry basis and 30g small-pore pseudo-boehmite (commercially available) on a dry basis into a mixer until uniform, then add 3g of scallop powder, 5g of volume ratio 1:1HNO 3 solution and 45g deionized water, grind evenly to make a dough suitable for extrusion. It is extruded through a die and is in the shape of a slender cylinder (diameter 1.7mm). After drying at 120°C, it is baked at 550°C for 4 hours, and then it is cut into carrier particles (1.7×4.0mm) of uniform size for use.

[0037] Prepare chloroiridic acid and barium nitrate in proportion to impregnate the carrier particles at 40°C. The dry basis weight of the carrier contained in the impregnating solution is 1% Ir and 3% Ba. After aging for 8 hours and drying, the Oxidation at 350°C in air for 4h, and reduction in hydrogen at 300°C for 4h (this step can be done in a reactor) to obtain the finished catalyst 1.

[0038] Catalyst 1 was used in a fix...

Embodiment 2

[0040]Add 70g of amorphous silica-alumina (commercially available) on a dry basis and 30g of small-pore pseudo-boehmite (commercially available) on a dry basis into a mixer until they are uniform, then add 3g of turnip powder and 5g of HNO at a volume ratio of 1:1 to the mixture. 3 solution and 45g deionized water, grind evenly to make a dough suitable for extrusion. It is extruded through a die and is in the shape of a slender cylinder (diameter 1.7mm). After drying at 120°C, it is baked at 550°C for 4 hours, and then it is cut into carrier particles (1.7×4.0mm) of uniform size for use.

[0041] Prepare chloroiridic acid and barium nitrate in proportion to impregnate the carrier particles at 40°C. The dry basis weight of the carrier contained in the impregnating solution is 1% Ir and 3% Ba. After aging for 8 hours and drying, the Oxidation at 350°C in air for 4h, and reduction in hydrogen at 300°C for 4h (this step can be completed in a reactor) to obtain the finished catalys...

Embodiment 3

[0044] Add 70g USY (commercially purchased) on a dry basis and 30g small-pore pseudo-boehmite (commercially purchased) on a dry basis into the mixer until uniform, then add 3g of kale powder, 5g of HNO at a volume ratio of 1:1 to the mixture 3 solution and 45g deionized water, grind evenly to make a dough suitable for extrusion. It is extruded through a die and is in the shape of a slender cylinder (diameter 1.7mm). After drying at 120°C, it is baked at 550°C for 4 hours, and then it is cut into carrier particles (1.7×4.0mm) of uniform size for use.

[0045] Prepare chloroiridic acid and barium nitrate in proportion to impregnate the carrier particles at 40°C. The dry basis weight of the carrier contained in the impregnating solution is 1% Ir and 3% Ba. After aging for 8 hours and drying, the Oxidation in air at 350°C for 4h, and reduction in hydrogen at 300°C for 4h (this step can be done in a reactor) to obtain the finished catalyst 3.

[0046] Catalyst 3 was used in a fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com