Thiol-modified graphene/carbon nanotube composite material and preparation method

A technology of carbon nanotubes and composite materials, applied in the field of nanomaterials, can solve the problems of low efficiency of functional group introduction, low degree of functionalization, and few surface active groups, and achieve the effect of convenient operation, good attraction, and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

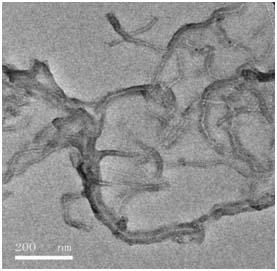

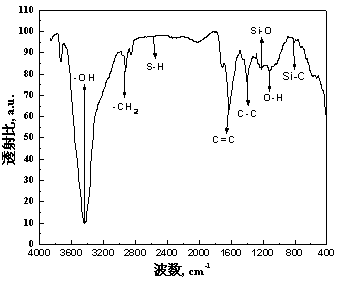

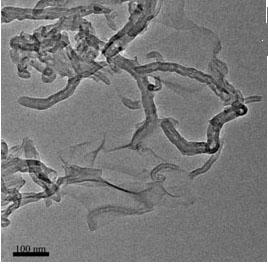

[0015] The preparation method of the graphene / carbon nanotube composite material of described thiol group modification, its steps are:

[0016] (1) Disperse carbon nanotubes in a mixed acid solution, react at 60-80°C for 1-3 hours, then filter and wash, and dry at 80-120°C for 8-12 hours to obtain purified carbon nanotubes;

[0017] (2) Add natural graphite to concentrated sulfuric acid with a mass fraction of 98%, stir mechanically until the graphite is completely dissolved, then add sodium nitrate and potassium permanganate to keep the temperature at 0~10°C, continue stirring for 2.5~4 hours, and Put the mixture in a constant temperature water bath at 35°C, slowly add deionized water, then put the mixture in a water bath at 90~100°C and stir mechanically for 20~40 minutes, add deionized water to dilute to 600ml, and stir for 5-15 minutes , adding 30% hydrogen peroxide by mass fraction, centrifuging the product at a speed of 8000-10000r / min, dispersing the centrifuged solid m...

Embodiment 1

[0025] Step 1, pretreatment of carbon nanotubes:

[0026] Disperse 1 g of original multi-walled carbon nanotubes (prepared by chemical vapor deposition) into a mixed acid solution of 30 ml of concentrated sulfuric acid and 10 ml of concentrated nitric acid, stir and react at 60°C for 3 hours, wash with distilled water until neutral, and dry in vacuum at 80°C for 12 standby after hours;

[0027] Step 2, the preparation of graphene oxide:

[0028] Take 2g of natural flake graphite with an electronic balance, use a graduated cylinder to measure 46ml of concentrated sulfuric acid and pour it into a 1000ml three-neck bottle, cool to 0~5°C, add the weighed 2g of graphite to 46ml of concentrated sulfuric acid, Use an ice bath to cool to 0~5°C and stir until the graphite is completely dissolved, add 1g of sodium nitrate and 6g of potassium permanganate at a certain speed while stirring vigorously, keep the temperature of the mixture below 10°C and continue stirring for 2.5 hours; rem...

Embodiment 2

[0034] Step 1, pretreatment of carbon nanotubes:

[0035] Disperse 2g of original multi-walled carbon nanotubes (prepared by chemical vapor deposition method) into the mixed acid solution of concentrated sulfuric acid and concentrated nitric acid, the volumes of which are 60ml and 20ml respectively, stir and react at 60°C for 3 hours, wash with distilled water until neutral , dried under vacuum at 80°C for 12 hours for later use;

[0036] Step 2, the preparation of graphene oxide:

[0037] Use an electronic balance to take 4g of natural flake graphite; measure 92ml of concentrated sulfuric acid in a graduated cylinder and pour it into a 1000ml three-neck bottle, cool it to 0~5°C, add the weighed 4g of graphite to 92ml of concentrated sulfuric acid, and use Cool in an ice-water bath to 0~5°C and stir until the graphite is completely dissolved. Add 2g of sodium nitrate and 12g of potassium permanganate at a certain speed while stirring vigorously to keep the temperature of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com