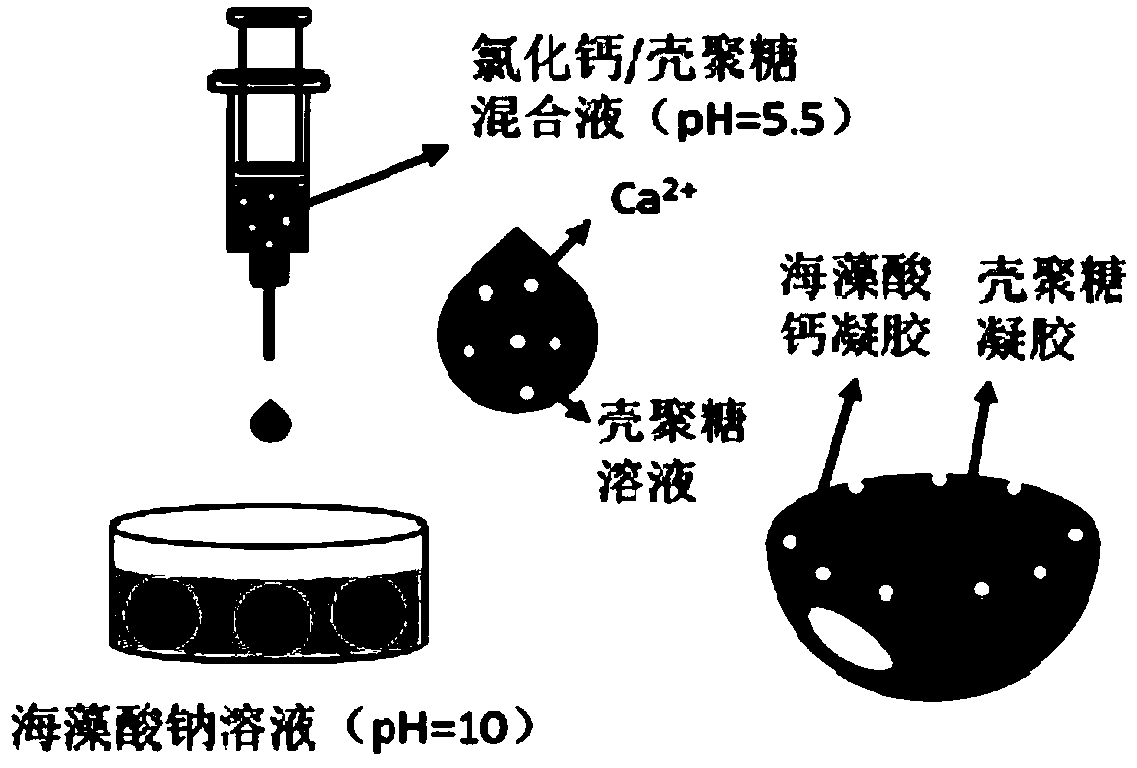

A method for preparing chitosan/sodium alginate natural polymer core-shell microspheres by one-step method

A technology of sodium alginate and polymer core, which is applied in the field of polymer materials and biomedical materials, can solve the problems of complex polymerization conditions and difficult control of the preparation process, and achieve good repeatability, low production cost and simple preparation steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

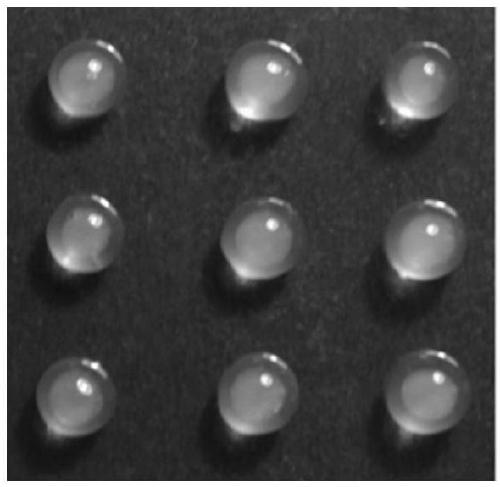

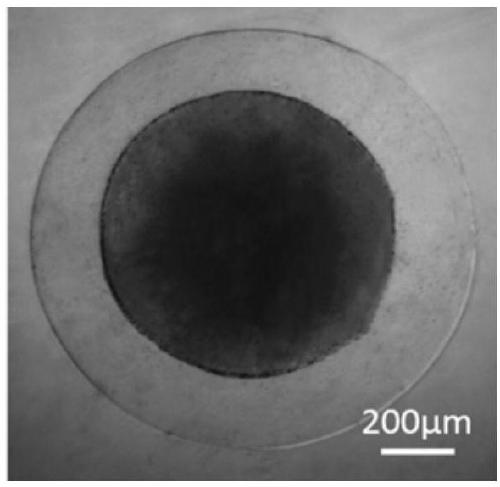

Examples

Embodiment 1

[0026] A method for preparing chitosan / sodium alginate natural polymer core-shell microspheres by one-step method, the preparation method is as follows:

[0027] (1) Prepare calcium chloride / chitosan mixed solution: get 15g chitosan solid powder, join in 500mL deionized water, stir 2 hours under normal temperature, then add the hydrochloric acid solution that molarity is 1.0mol / L to adjust the solution The pH is 5.5, and stirred for 8 hours until the chitosan is fully dissolved, and then filtered through a sand core funnel to prepare a chitosan solution that the mass volume ratio concentration is 3% (w / v); get 1.11g calcium chloride solid powder , added to 100mL of the above-mentioned chitosan solution, stirred at room temperature for 2 hours until the calcium chloride was completely dissolved, and the calcium chloride / chitosan mixed solution with a calcium chloride molar concentration of 0.1mol / L was prepared;

[0028] (2) Preparation of sodium alginate solution: Take 2g of s...

Embodiment 2

[0039] A method for preparing chitosan / sodium alginate natural polymer core-shell microspheres by one-step method, the preparation method is as follows:

[0040] (1) prepare calcium chloride / chitosan mixed solution: get 10g chitosan solid powder, join in 500mL deionized water, stir 2 hours under normal temperature, then add the hydrochloric acid solution that molarity is 1.0mol / L to adjust the solution The pH is 5.5, and stirred for 8 hours until the chitosan is fully dissolved, and then filtered through a sand core funnel to prepare a chitosan solution that the mass volume ratio concentration is 2% (w / v); get 0.222g calcium chloride solid powder , added to 50mL of the above-mentioned chitosan solution, stirred at room temperature for 2 hours until the calcium chloride was completely dissolved, and the calcium chloride / chitosan mixed solution with a calcium chloride molar concentration of 0.04mol / L was prepared;

[0041] (2) Preparation of sodium alginate solution: Take 1 g of...

Embodiment 3

[0044] A method for preparing chitosan / sodium alginate natural polymer core-shell microspheres by one-step method, the preparation method is as follows:

[0045] (1) Preparation of calcium chloride / chitosan mixed solution: get 30g chitosan solid powder, join in 600mL deionized water, stir for 1 hour at normal temperature, then add the hydrochloric acid solution that molar concentration is 1.2mol / L to adjust the solution The pH is 5.0, and stirred for 10 hours until the chitosan is fully dissolved, and then filtered through a sand core funnel to prepare a chitosan solution with a mass-volume concentration of 5% (w / v). Take 3.33g of calcium chloride solid powder, add it to 100mL of the above-mentioned chitosan solution, stir at room temperature for 3 hours until the calcium chloride is completely dissolved, and prepare calcium chloride / chitosan with a calcium chloride molar concentration of 0.3mol / L sugar mixture;

[0046] (2) Preparation of sodium alginate solution: Take 6g of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com