Welding soot purifier

A welding fume and purifier technology, applied in chemical instruments and methods, combined devices, gas treatment, etc., can solve the problems of inability to use the air in the workplace, cracking of waste gas molecules, reducing purification efficiency, etc., to achieve light weight, reduce Damage, increase the effect of purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

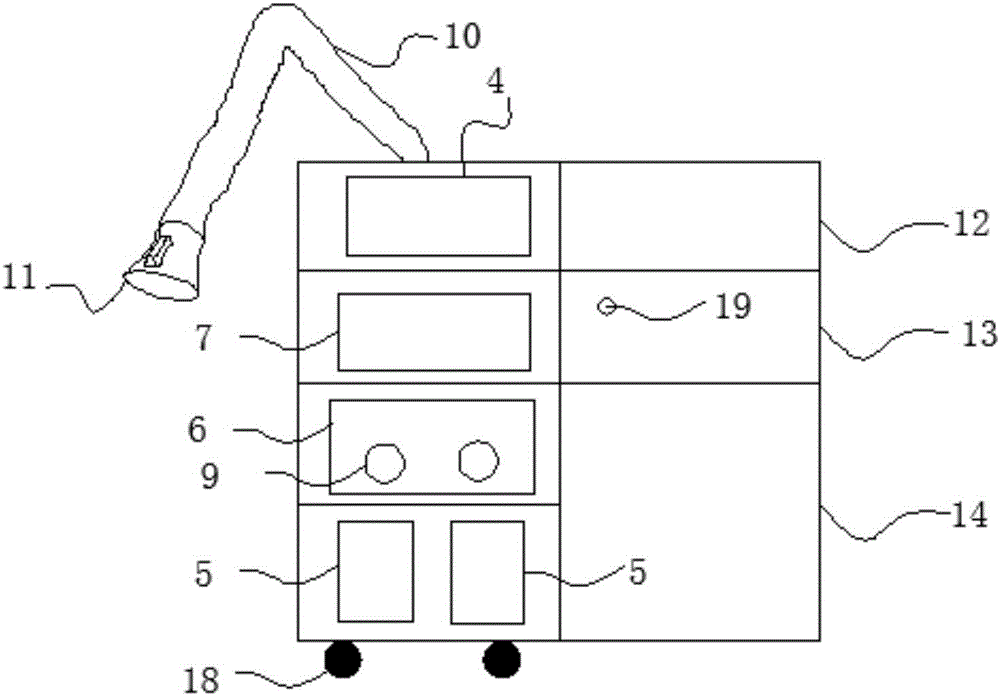

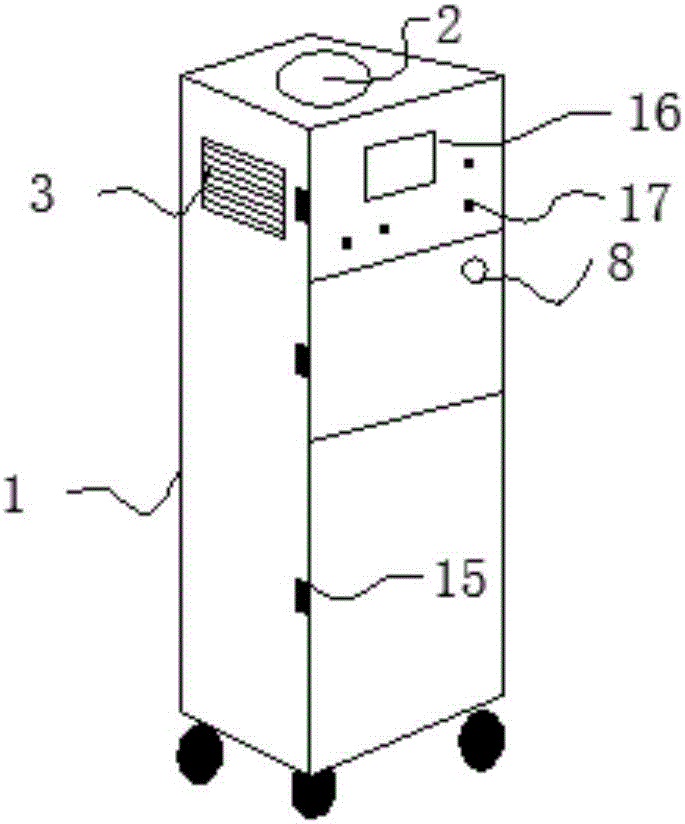

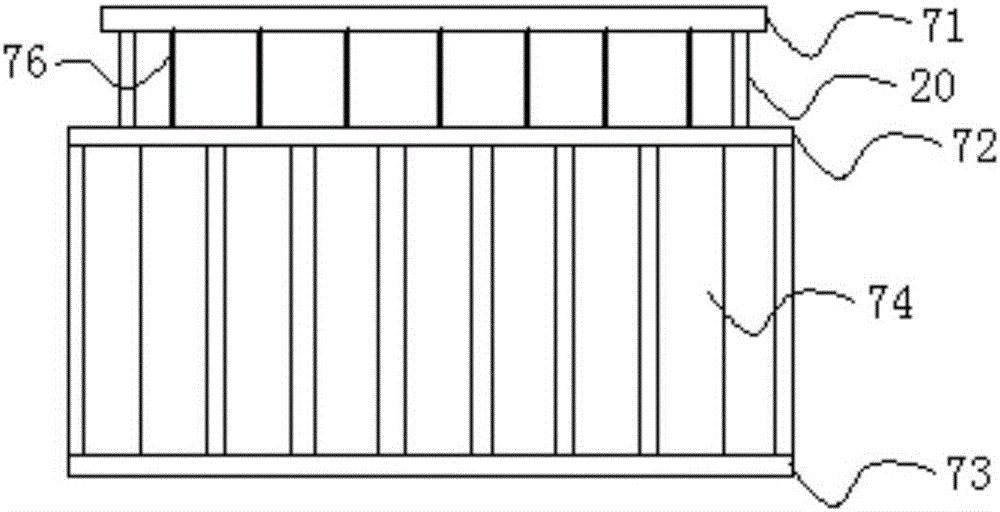

[0032] Embodiment: a kind of welding fume purifier, as Figure 1-4As shown, it includes a housing 1 and a PLC control device 4 arranged in the housing 1. The housing 1 is provided with an air inlet 2 and an air outlet 3. Between the air inlet 2 and the air outlet 3 An air flow channel is formed between them, the air flow channel is located in the housing 1, and the housing 1 is provided with a film-coated filter cartridge 5 and an anion dedusting device 7 in sequence according to the gas flow direction, and the film-coated filter cartridge 5 is provided with At least one (concrete number can be set according to usage), described air passage is also provided with induced draft fan, and described negative ion dedusting device 7 and described induced draft fan are all electrically connected with described PLC control device 4;

[0033] The PLC control device 4 includes a power supply control unit and a PLC control unit, the power supply control unit is electrically connected to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com