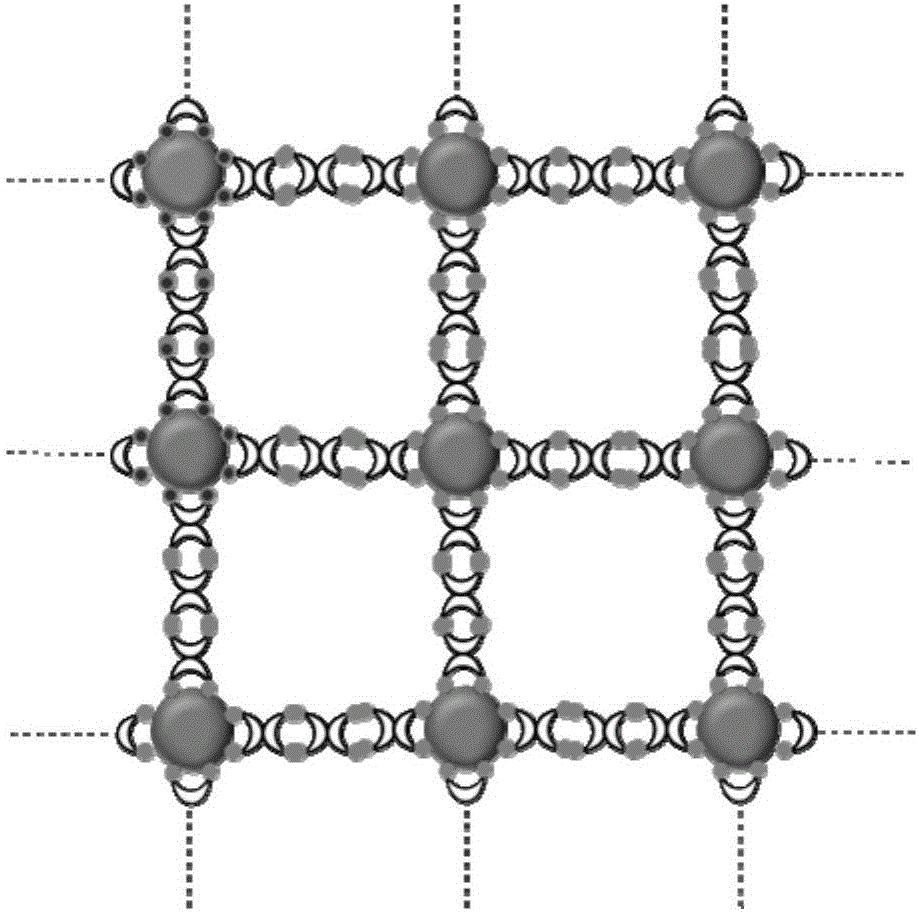

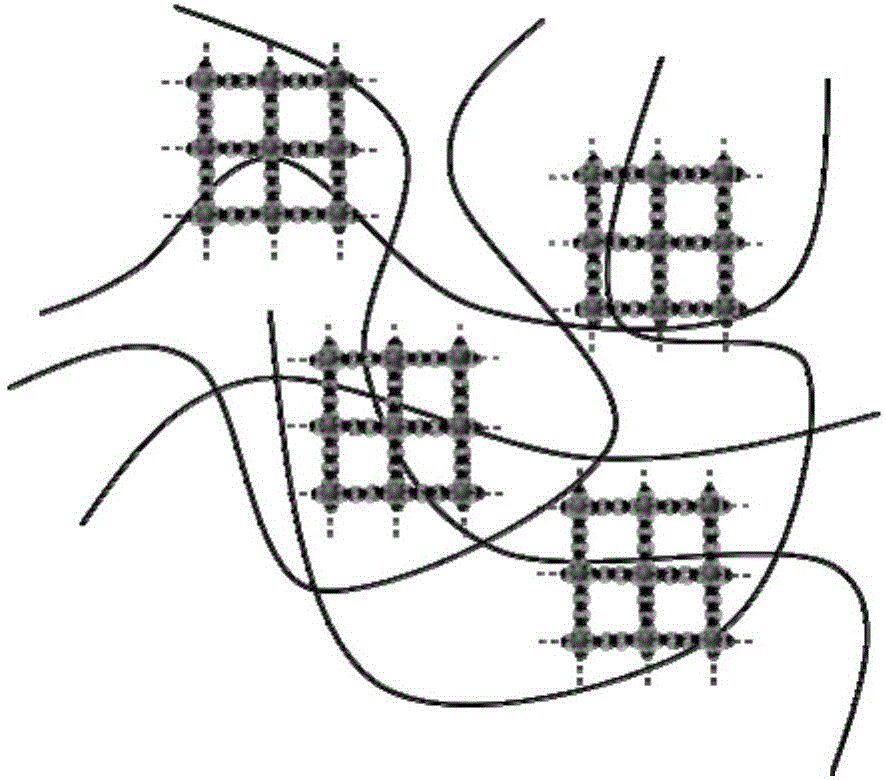

Clustered nanocrystal networks and nanocrystal composites

A technology of nanocrystals and composite materials, applied in the fields of nanotechnology, nano-optics, luminescent materials, etc., can solve problems such as increase in defects, deterioration of initial luminescence properties, negative effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0079] The preparation method according to the invention does not involve any additional solvents and preferably does not involve the use of heavy metals.

[0080] The NC-composites according to the invention can be used in a wide range of applications by merely changing the chemical composition of the nanocrystals.

[0081]For example, clustered nanocrystal networks of CuInS are suitable for display applications; PbS for solar cells; CuZnSnS for solar cells; CuFeSbS for thermoelectric applications; and FeSeS for magnetic applications.

[0082] The present invention also covers products comprising nanocrystalline composites according to the invention, which products may be selected from display devices, light emitting devices, photovoltaic cells, photodetectors, energy converter devices, lasers, sensors, thermoelectric devices, security inks and in catalytic or biomedical applications. In a preferred embodiment, the product is selected from displays, lighting and solar cells....

Embodiment 1

[0086] CuInSeS / ZnS / ZnS-tris[2-(3-mercaptopropionyloxy)ethyl]isocyanurate (CuInSeS / ZnS / ZnS-TEMPIC) clustered NC network in polysiloxane matrix

[0087] 0.2g (i.e. 10% by weight) NC bulk powder (bulk powder) (CuInSeS / ZnS / ZnS:TEMPIC) was mixed into 1.8g (i.e. 90% by weight) of two-component optical polysiloxane (i.e. NuSil Lightspan 6140) . The resulting formulation was mixed for 2 minutes at 3000 rpm in an adapted mixer. Subsequently, the mixture was dispensed into aluminum cups using 1 ml plastic pipettes and heat cured at 150 °C for 15 min. An orange-emitting semiconducting NC-composite was obtained.

[0088] Clustered NC network synthesis:

[0089] 0.08g CuI, 0.4g In(OAc) 3 and 0.16ml stock solution DPPSe was dissolved in 10ml TEMPIC. The mixture was heated at 190°C for 10 minutes. 0.6g Zn(OAc) 2 2H 2 A mixture of O in 5 ml TEMPIC was added to the nuclei solution, and the mixture was heated at 230°C for 60 minutes. Then 0.6g ZnSt 2 The mixture in 5 ml TEMPIC was add...

Embodiment 2

[0091] CuInSeS-pentaerythritol tetrakis(3-mercaptopropionate) (CuInSeS-PEMP) clustered NC network

[0092] Clustered NC network synthesis:

[0093] 0.5g CuI, 2.5g In(OAc) 3 and 1 ml stock solution DPPSe dissolved in 10 g PEMP. The mixture was heated at 210°C for 10 minutes. A red semiconducting colloidal NC solution (CuInSeS-PEMP) was obtained. Subsequently, 5 ml of the resulting solution was quenched with excess acetone at 200 °C. The mixture was allowed to settle at room temperature and then dried in an oven at 120°C for 3 hours. The obtained solid was mechanically ground until a fine powder was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com