Efficient production of composite semifinished products and components in a wet pressing method using hydroxy functionalized (meth)acrylates which are duroplastically crosslinked using isocyanates or uretdiones

A technology of isocyanate components and composite materials, applied in the direction of synthetic resin layered products, chemical instruments and methods, lamination, etc., to achieve the effect of improving heat deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

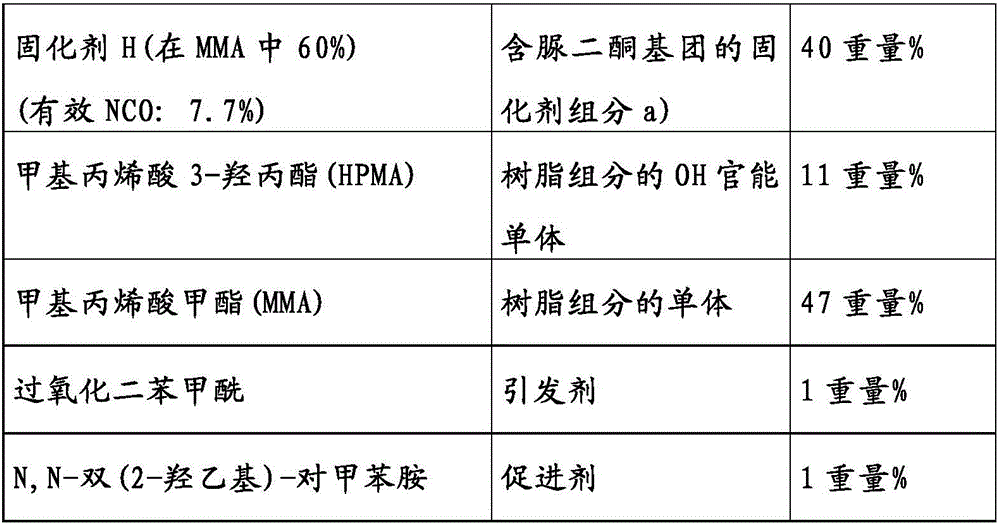

[0131] Table 1

[0132]

[0133] To manufacture the assembly, 10 layers of glass fiber cloth are stacked on top of each other in a metal mold measuring 25×25 cm and purged with nitrogen.

[0134] The ingredients in this table were mixed in a premixer and then dissolved. This mixture can be used at room temperature for about 15 minutes before it gels.

[0135] The matrix is then applied to the fibers. During the closing operation, this matrix distributes and wets the reinforcing fibers within the mold. After 20 minutes, the reaction at room temperature is completely over and the preform (here synonymous with semi-finished product) can be removed from the mold. The preform of Example 1 exhibited a weight loss, based on the matrix, of approximately 2% by weight after the reaction.

[0136] The preform was then pressed in another mold at 180° C. and 50 bar for 1 hour, during which time the matrix material was completely crosslinked. The hard, rigid, chemical and impact r...

Embodiment 2

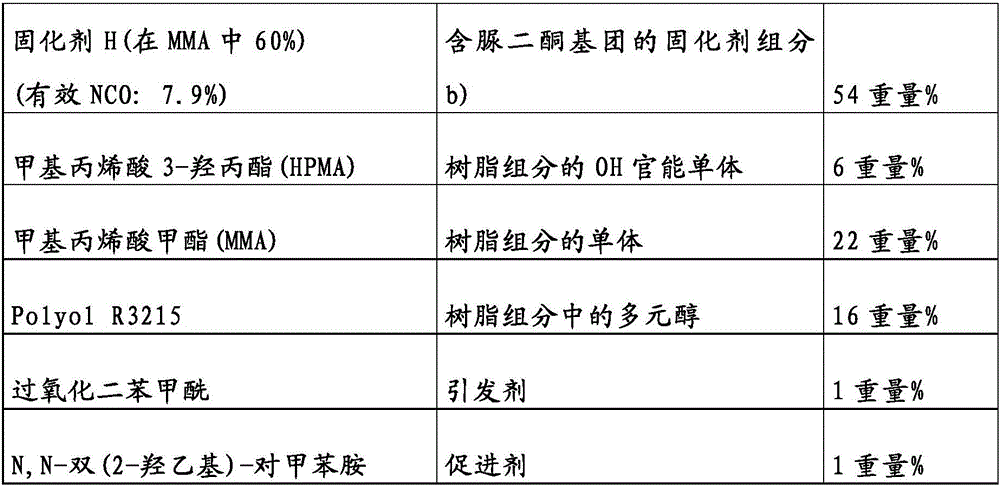

[0138] In Example 2, it proceeds analogously to Example 1. The only difference is the use of a resin component that additionally contains non-(meth)acrylic polyols. The composition is derived from Table 2.

[0139] The implementation procedure of embodiment 2 is carried out according to embodiment 1. The weight loss of the preform after the reaction was determined here to be 1% by weight instead of 2% by weight as in Example 1. The hard, rigid, chemical and impact resistant composite component (sheet) has a glass transition temperature T of 80°C g And overall slightly more flexible than the sheet from Example 1.

[0140] Table 2

[0141]

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com