Easy-to-weld ultra-thick steel plate with high strength and high toughness suitable for minus 60 DEG C and manufacturing method thereof

A technology of ultra-thick steel plate and high toughness, which is applied in the field of low-temperature special steel plate manufacturing. It can solve problems such as unsatisfactory weldability and achieve excellent high-strength and high-toughness effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1:890℃,1.8min/mm,。 Embodiment 2

[0038] After slow cooling, the steel plate enters the continuous furnace for quenching treatment. Example 1: The heating temperature is 890°C, the time in the furnace is 1.8min / mm, and water quenching is used in a quenching machine. Example 2: The heating temperature is 910°C, the time in the furnace is 2.0min / mm, and water quenching is used in a quenching machine. The quenched steel plate is tempered in a continuous furnace. Embodiment 1: The heating temperature is 630°C, and the furnace time is 4.0min / mm. Embodiment 2: The heating temperature is 660°C, and the furnace time is 4.0min / mm.

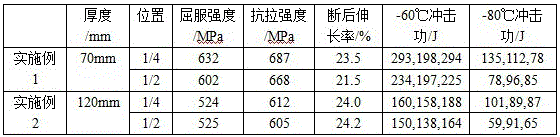

[0039] The chemical composition of the steel plate that embodiment 1 and 2 makes is shown in Table 1, and the mechanical property of steel plate is shown in Table 2, and the microstructure of steel plate is as follows figure 1 and figure 2 shown.

[0040] Table 1 Chemical composition (wt.%) of easy-weldable high-strength and high-toughness lamellar tear-resistant steel sheets in Exampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com